Standard Industrial Pump Tubes

Our complete range of pump tubes provide an ideal solution for applications ranging from corrosive chemicals to light oils. Pump tubes are available in polypropylene, PVDF, CPVC, stainless steel and aluminum.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

See below for complete range of Industrial Pump Tubes

Technical Specifications

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Centrifugal

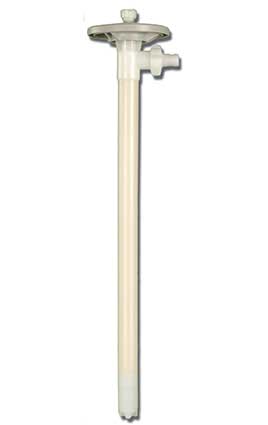

Polypropylene

Engineered for transferring a variety of corrosive liquids. Robust Polypropylene ensures chemical resistance against light to aggressive chemicals. Not suitable for pumping flammable or combustible liquids.

Applications

- Acetic Acid

- Sulfuric Acid

- Hydrochloric Acid (20%)

- Nitric Acid (20%)

- Alkalis

- Ferric Chloride

Centrifugal

Stainless Steel*

Engineered for transferring flammable and combustible liquids as well as light oils and suitable chemicals. Robust Stainless Steel 316 offers excellent strength and durability.

Applications

- Alcohol

- Isopropyl Ether

- Gasoline

- Solvents

- Aquenos Ammonia

- Petroleum Products

Centrifugal

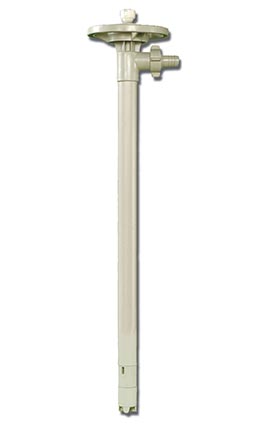

CPVC

Engineered for transferring corrosive chemicals associated with the water treatment industry. Robust CPVC offers excellent durability and chemical resistance. Not suitable for pumping flammable or combustible liquids.

Applications

- Sodium Hypochlorite

- Calcium Chloride

- Potassium Hydroxide

- Calcium Hydroxide

- Chlorinated Water

- Sodium Bromide

Centrifugal

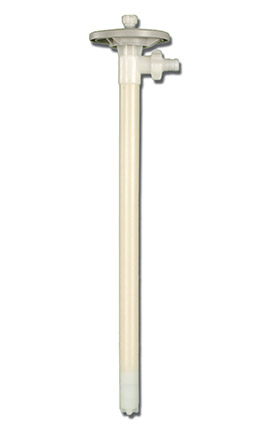

PVDF

Engineered for transferring highly concentrated and aggressive liquids. Robust PVDF offers excellent durability and chemical resistance. Not suitable for pumping flammable or combustible liquids.

Applications

- Concentrated Nitric Acid

- Propionic Acid

- Hydrofluoric Acid

- Sodium Hypoclorite

- Sulfuric Acid-66

- Stearic Acid

Centrifugal

Aluminum*

Engineered for transferring non-corrosive liquids such as machining oils, coolants and hydraulic fluid. Robust Aluminum construction offers excellent strength and durability.

Applications

- Motor Oil (up to 30 wt)

- Anti-Freeze

- Lubricating Oils

- Light Machining Oils

- Hydraulic Fluid

Progressive Cavity

Planetary Gear*

Engineered to transfer viscous materials from drums and intermediate bulk containers (IBC). The progressive cavity design delivers a continuous flow of material with little product degradation. Pumps are available with TEFC and Hazardous Duty motors. Maximum viscosity is 25,000 cps (mPas).

Applications

- Polymers

- Oil & Greases

- Resins

- Paints

- Adhesives

- Varnishes

Progressive Cavity

Direct Drive*

Engineered to transfer viscous materials from drums, intermediate bulk containers (IBC) and large storage vessels. Utilizing the principle of positive displacement, these pumps deliver a continuous flow of material with little product degradation. Pumps are available with a TEFC electric or air powered motors. Maximum viscosity is 100,000 cps (mPas).

Applications

- Polymers

- Oil & Greases

- Resins

- Paints

- Adhesives

- Varnishes

*Pumping of flammable or combustible liquids can generate a static electric discharge, causing fire or explosion resulting in injury or death. Read and understand operating instructions before starting this unit. Follow all federal, state and local safety codes including NFPA 30 - NFPA77. Prior to connecting to air supply, install bond and ground wires and check continuity of each wire. A meter reading of one ohm or less is required for safe liquid transfer. Use only approved metallic pump tube, explosion proof or air motor, metallic drum and receiving vessel when pumping flammables. Air motors are not recognized under any current Underwriter’s Laboratory listing program. Consult a qualified engineer for suitability for use in a hazardous area or on flammables.