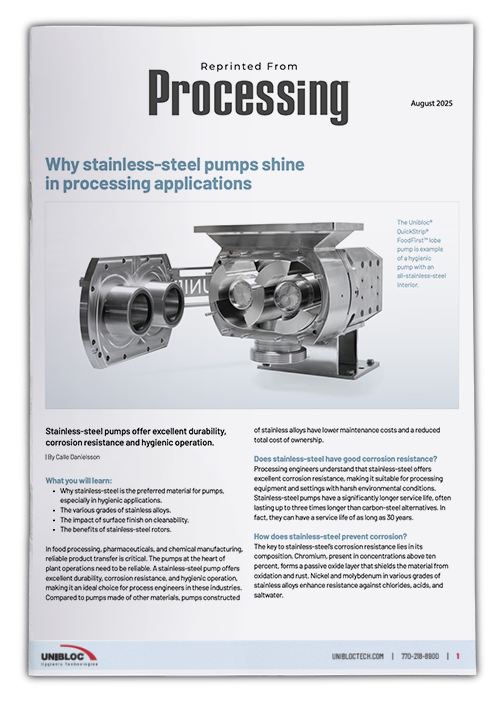

Stainless-steel pumps offer excellent durability, corrosion resistance and hygienic operation. Learn how the various grades of stainless alloys, surface finish and other factors affect which stainless-steel pump is the right fit for you.

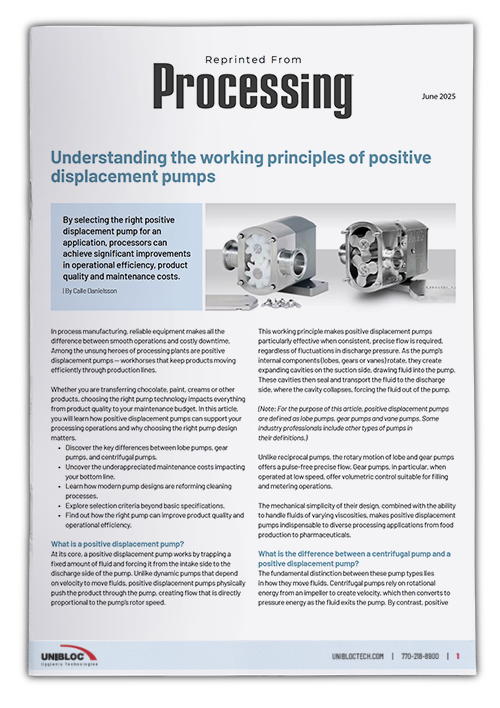

Read ArticleBy selecting the right positive displacement pump for an application, processors can achieve significant improvements in operational efficiency, product quality and maintenance costs. Read how the right equipment makes all the difference.

Read ArticleMany processes involve the hygienic transfer of viscous products, from sauces to silicone. These thick materials pose special challenges to the pumping process. Fortunately, engineering principles are easy to grasp, and once understood, they can help engineers avoid common mistakes.

Read ArticleEvery food processor has a story about plant equipment leaving a bitter taste. For example, operators ran a viscous product through a centrifugal pump designed for thin liquids to accommodate a new product. They discovered the tomato chunks became tomato soup. In many cases, the pump is not to blame; rather, the wrong type of pump is being used for the application.

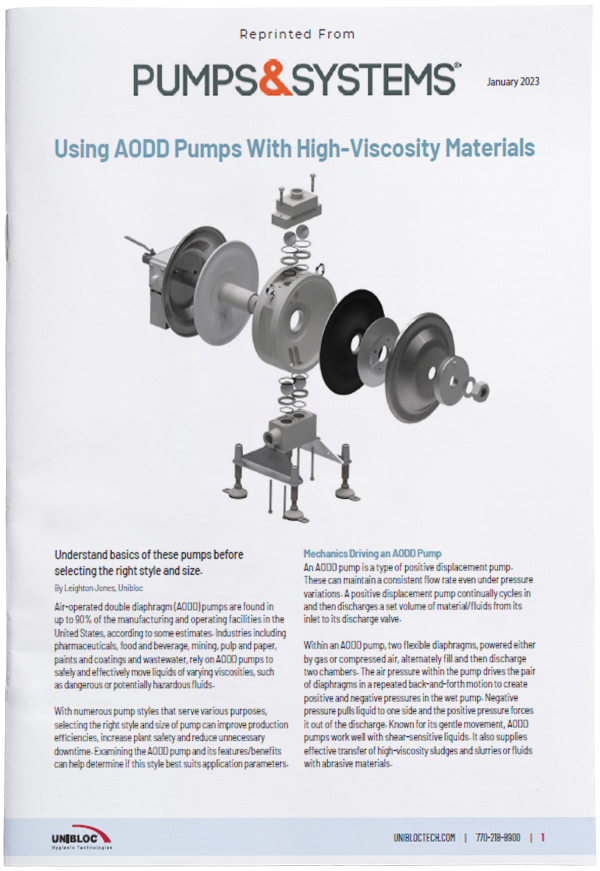

Read ArticleOne estimate shows that at least 75% of food manufacturers in the UK have an air-operated double diaphragm (AODD) pump. To avoid negative impacts on operations and maintenance budgets, operators should understand when an AODD pump is the ideal choice.

Read ArticleThe ongoing shortage of skilled workers in the food processing industry underscores the need for easily serviceable and reliable equipment.

Read ArticleFood & Beverage Magazine editors select Unibloc® QuickStrip® series pumps for its Top Pick Industry Excellence award.

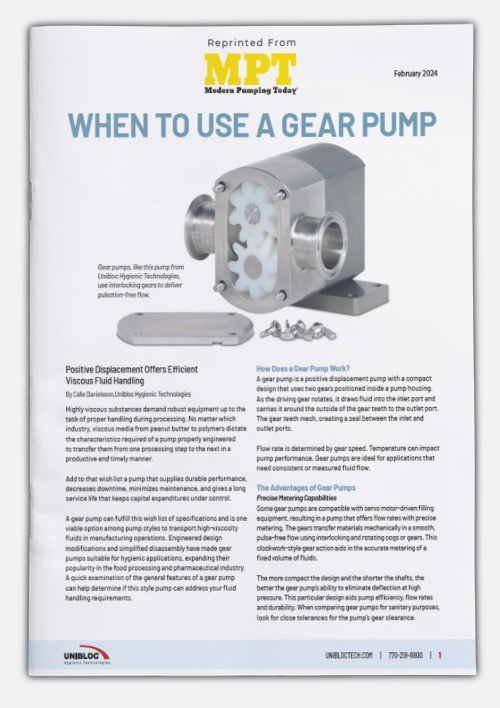

Read ArticleNo matter which industry, viscous media from peanut butter to polymers dictate the characteristics required of a pump properly engineered to transfer them from one processing step to the next in a productive and timely manner.

Read ArticleWith numerous pump styles that serve various purposes, selecting the right style and size of pump can improve production efficiencies, increase plant safety and reduce unnecessary downtime. Examining the AODD pump and its features/benefits can help determine if this style best suits application parameters.

Read ArticleA well-made and properly designed sanitary pump used as intended should last for many years with minimal maintenance. Still, as with any machine, sanitary pumps do have wear items and operating parameters that, when compromised, can impact the life span of equipment and ultimately the quality of the product produced in the facility.

Read ArticleEn los establecimientos de procesamiento de carne, una bomba con fugas es un problema común y frustrante al que se enfrentan los ingenieros de mantenimiento.

Read ArticleThe sanitary pumps used in food and beverage and pharmaceutical processing have special requirements that impact their overall cost. This is because of their critical role in safety and their need to be thoroughly cleaned. When selecting a pump for a processing line, total cost of ownership (TCO) should not be left until the end of the discussion.

Read ArticleIn the wake of the COVID-19 pandemic, the United States is currently experiencing a labor shortage impacting both manufacturers and consumers. From products, equipment, and supplies stranded offshore to a shortage of manpower throughout the supply chain, this is a challenging time for manufacturers.

Read ArticleSanitary pumps are used in nearly every food and beverage processing plant to transport oils, slurries, additives, flavorings, sugars, meats/poultry, and more from hoppers to grinders, mixers, formers and primary packaging lines. These pumps must be properly maintained and serviced to meet food safety standards and ensure productivity and product integrity.

Read ArticleOh no! There are no results matching this filter combination.

Try another filter combination, or .