Positive Displacement Pumps

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

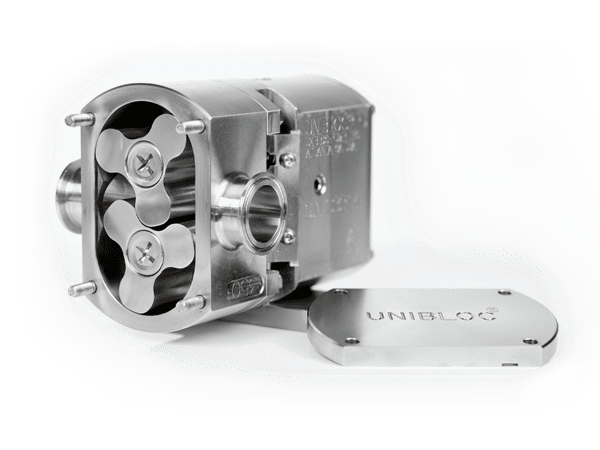

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications.

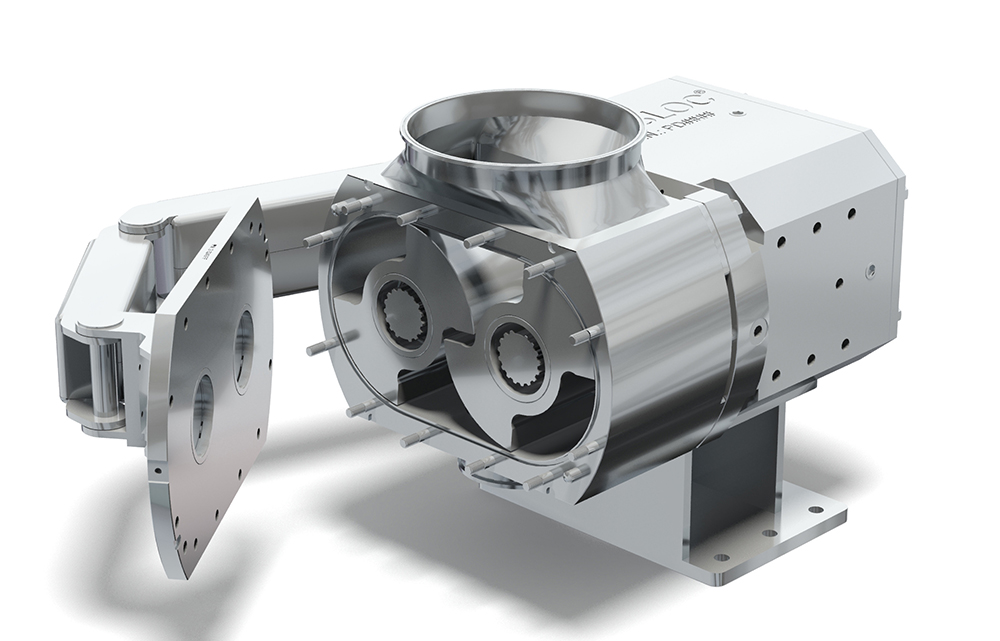

A fully machined gearbox at its core, this lobe pump sets the highest industry standards for performance, providing sanitary solutions for a variety of applications.

"Looking for bigger and better? The Unibloc® UltraLobe™ FoodFirst 700 Series Pumps answer that quest with a lobe pump that possesses all the qualities of our popular QuickStrip FoodFirst 600 Series—and delivers more. Double or triple your throughput in a similar footprint to the 600 series. Maximize the ROI of every square foot of your plant space while preserving safety"