Standard Pump Fluid Handling Equipment

Serving the Chemical, Water Treatment, Plating, Adhesives, Automotive, and General Industrial Industries in 52 Countries, UHT’s Standard Pump brand started manufacturing Drum Pumps in Georgia in 1992 and has since expanded to include industrial drum pump packages, DEF pumps, metering systems and pump lifts.

Designed to safely transfer corrosive chemcials from drums, IBC's and Tote tanks. When you need fluid handling equipment for your chemical, industrial, water treatment or automotive application, you can have confidence in the safety and performance of our Drum Pumps.

Standard Diesel Exhaust Fluid Pump

Engineered to transfer Diesel Exhaust Fluid (DEF) / AdBlue directly from drums and intermediate bulk containers (IBC). These pumps meet stringent North American and European safety standards.

Standard Industrial Pump Motors

Standard Pump motors are designed to operate in the most demanding of environments. An extensive line of Explosion Proof, TEFC, Open Drip-Proof and air motors provide durability and safety regardless of the environment.

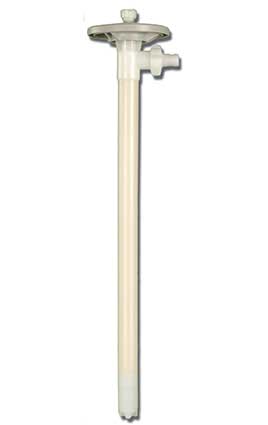

Standard Industrial Pump Tubes

Our complete range of pump tubes provide an ideal solution for applications ranging from corrosive chemicals to light oils. Pump tubes are available in polypropylene, PVDF, CPVC, stainless steel and aluminum.

Standard Industrial Drum Pump Accessories

Customize your industrial Drum Pump with selection of accessories. Hand Nozzles provide a safe solution for controlling and dispensing corrosive chemicals. Barrel Adapters vertically stabilize pumps in drums and Fume Barriers reduce aggressive fumes in the atmosphere.

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Safety Comes Standard

As with all UHT’s brands, Standard Pump products adhere to stringent safety guidelines and are committed to providing high-quality equipment – so when you need fluid handling for your applications, you can have confidence in the safety and performance of our Standard Pump line of products.

For two generations, the Standard Pump product lines have stood for quality Industrial Drum Pumps that customers rely on for:

- Precision design and quality construction

- A safe solution for transferring corrosive media

- A diverse range of pump solutions for a wide variety of demanding applications

Quick Links

From the Blog

View BlogTwin Screw vs. Lobe Pump? Which Pump is the Better Choice for Suspended Solids?

As food processors respond to rising consumer demand for protein-enriched products, from high-protein yogurts to enhanced dairy beverages, production lines face increasing challenges with thick, viscous formulations. With the food processing automation market approaching $40 billion by 2030, the industry seeks equipment capable of handling complex products without compromising throughput or quality.

Read BlogComparing Hygienic Pump Technology Pros and Cons: A Process Engineer’s Guide

In hygienic processing environments, pump selection plays a far greater role than simply moving product from point A to point B. The pump directly influences product integrity, ensuring easy cleaning, reducing food safety risks, minimizing maintenance efforts, and lowering total cost of ownership. For process engineers working in food, beverage, personal care, or pharmaceutical applications, understanding which hygienic pump technology is best designed for each application is essential to building reliable, repeatable processes.

Read BlogChallenging Pump Applications, Meet Your Match

The ultimate guide to knowing when to use twin screw pump technology —don’t let viscosity slow you down

Read Blog