Industrial Pumps

When you need fluid handling equipment for your chemical, industrial, water treatment, printing, manufacturing, or automotive application, you can have confidence in the safety and performance of our pumps.Because safety comes standard with our pumps, you know you’re installing the best-engineered solution backed by our unmatched warranty. When you need fluid handling equipment for your chemical, industrial, water treatment, printing, manufacturing, or automotive applications, you can have confidence in the safety and performance of UHT products.

Our product line offers a comprehensive range of chemically resistant Drum Pumps for the most demanding applications such as transferring concentrated nitric and sulfuric acid. Standard pump products use high quality materials like Polypropylene, PVDF and Hastelloy to ensure the operator’s safety. They are easy to maintain, and many units offer diaphragm rupture systems to address employer and environmental safety issues.

Automotive

The automotive industry deals with a diverse (and often expensive) range of paints and other process materials that need to be pumped safely and controlled. These materials can be exceptionally challenging; many are of particularly high viscosity and often contain abrasive additives.

Printing

The printing industry handles a diverse range of inks and fluids, some of which present highly challenging process characteristics. Fluids in this industry can be of especially high viscosity, and they often contain abrasive additives.

Manufacturing/Chemical Processing

The manufacturing industry deals with everything from coatings to solvents to coolants to hydraulic fluids and everything in between. Many of these process materials are hard to handle, caustic, abrasive and at times hazardous, and therefore require the very best performance from your pump.

- Transferring any product up to 300,000 Cps

- Ability to pump particles up to 25mm cube

Water Treatment

One of the largest end-user segments of the diaphragm pump market is the water treatment industry. Diaphragm pumps are essential for treatment processes like coagulation, iron sequestration, disinfection, and helping with odor control, phosphorous control, and solid conditioning.

From the Blog

Important Chemical Considerations for Industrial Pumps

Chemical Drum Pumps and the Dangers Involved

The 5 Most In-Demand New Features of Chemical Drum Pumps

Upcoming Events

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Explore Solutions

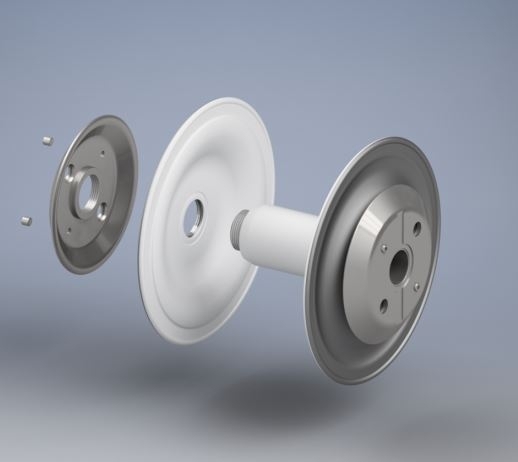

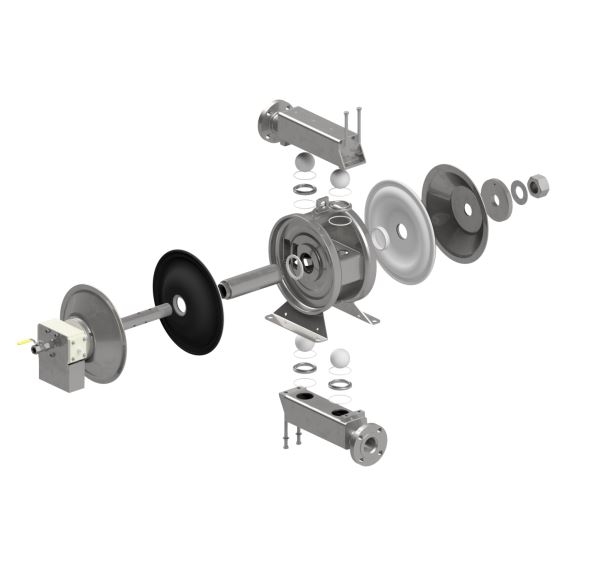

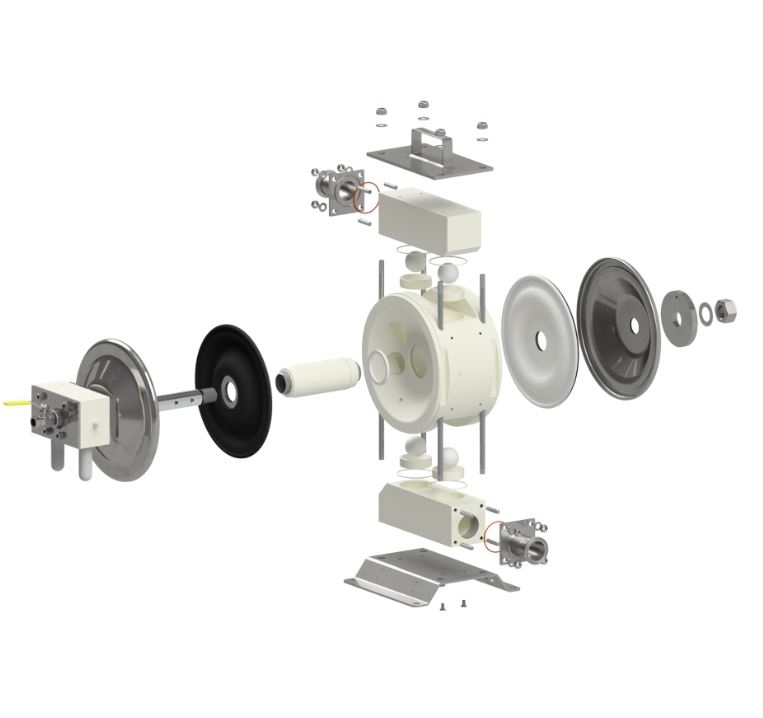

One-Nut Double Diaphragm Industrial Pumps

The One-Nut Air-Operated Double-Diaphragm pump takes pump performance far beyond traditional style doubled diaphragm pumps. This fast maintenance concept literally turns the conventional pump inside out.

Because safety comes standard with our Drum Pumps, you know you’re installing the best-engineered solution. When you need fluid handling equipment for your chemical, industrial, water treatment, or automotive application, you can have confidence in the safety and performance of our Drum Pumps.

Industrial Drum Pump Accessories

Customize your industrial drum pump with a selection of accessories. Hand Nozzles provide a safe solution for controlling and dispensing corrosive chemicals. Barrel Adapters vertically stabilize pumps in drums and Fume Barriers reduce aggressive fumes in the atmosphere.