AODD Pump Transferring Adhesive

When an International Adhesive manufacturer needed to increase their flow of adhesive they turned to their supplier of Air-Operated Double-Diaphragm pumps.

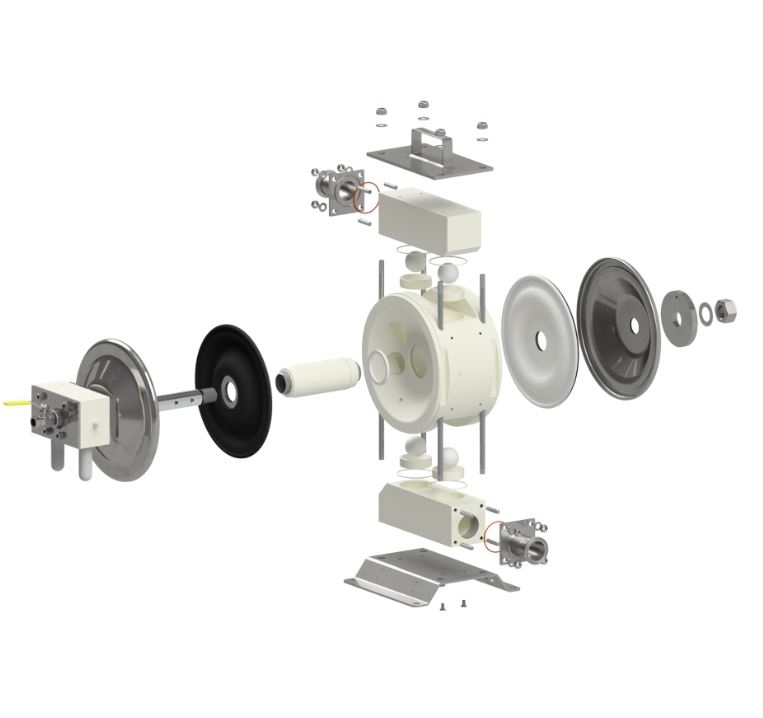

For over six years thier "One Nut" fast maintenance AODD Pumps from FPL had been working successfully at the manufacturers UK plant, replacing the old style diaphragm pumps which suffered from continuous leaks, particularly around the clamp bands.

The pumps are used to transfer the water based adhesive from bulk storage vessels into the mixing farm, where further ingredients are added to alter the adhesive properties to cater for different applications.

A flowrate of 500 litres/min is required and the adhesive has a viscosity of between 500 - 1,000 cp at ambient temperature. The pumps have a flooded suction and discharge the media 3 metres vertical and over a 10 metre distance.

"We switched to Flotronic over five years ago" comments the plant's Maintenance Manager, "because they are so maintenance friendly. In fact pump failures are very rare, but should they occur, then the "One Nut" feature is such a benefit, not like our previous old style pumps which could take hours to strip!".

PROCESS DETAILS

- Water based adhesive

- 500 l/min flowrate

- Viscosity 500 – 1,000 cp

- Flooded suction

- Discharge 3 M vert. 10 M horizontally

PUMP DETAILS

- 500 Series Polyprops

- 3" Flanged

- PTFE Elastomers