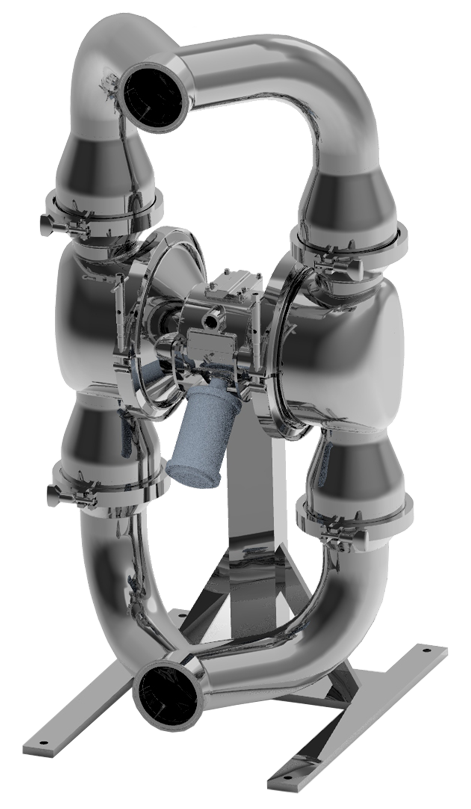

Air-Operated Double-Diaphragm Plus Pumps

Featuring One-Nut Technology

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs, with One-Nut technology that takes AODD+ pump performance far beyond the traditional. This fast maintenance concept literally turns the conventional pump inside-out.

Flotronic® Good Food Pump- Food Grade AODD Pump

Double Diaphragm Pump ideal for pumping your food products, especially on high viscosity low shear applications. Designed for ‘quick strip’ which is tool free or the pumps can be ‘cleaned in place’ (CIP), manufactured throughout from FDA compliant approved materials. The 'Good Food' pump gives food industry customers very specific benefits.

A compact and self-draining Diaphragm Pump available in FDA approved 316L stainless steel, aluminium, Duplex 22, and Hastelloy®; used in an array of industries.

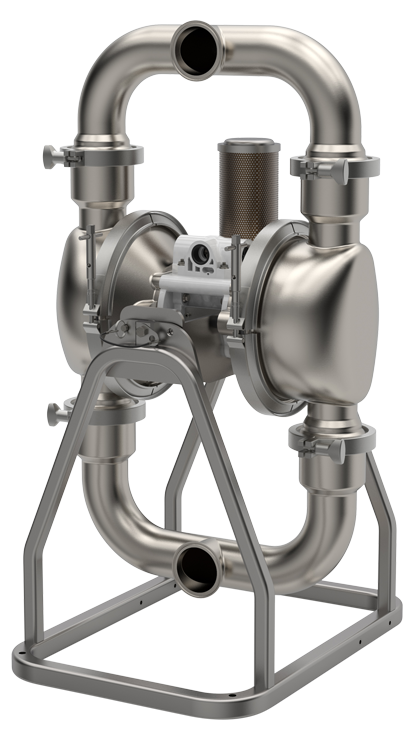

Flotronic® 710 Series Stainless Steel Pump

Fabricated 316L stainless steel or Hastelloy® on all wetted metal parts offers unrivaled versatility. These FDA compliant Air-Operated Double-Diaphragm Pumps are used extensively throughout the industry.

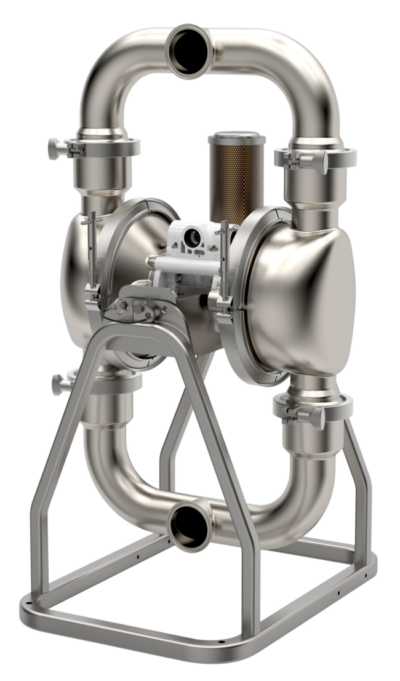

Flotronic® Sanitary AODD+ Pump

Designed with 3A in mind using FDA, USP Class VI and (EC) 1935/2004 approved materials; our range of Sanitary Diaphragm Pumps help maintain and improve hygienic conditions on your site.

Flotronic® One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut pump meets your application requirements.

Hygenitec™ Large Solids AODD Pump

Designed specifically for hygienic applications requiring the transfer of solids up to 3.8” (96.5mm). Applications include the transfer of fruit and vegetables suspended in water, pie fillings, wine processing and ice cream production.

Hygenitec™ Poultry Processing AODD Pump

The Poultry Processing pump was designed to transfer chicken tenders, disjointed wings, giblets and waste products. The pump features a unique Flap Check design which protects the integrity of the product. Available in vertical or horizontal configurations.

Hygenitec™ Food Grade AODD Pump

FDA compliant pumps are engineered for food and cosmetic applications and are constructed with the FDA approved materials for food contact. These pumps are stainless steel and feature Tri-Clamp® fittings for quick knockdown and cleaning.

Constructed with polished stainless steel 316, these pumps are designed for sanitary process applications where a hygienic design is critical. The pumps are mounted on a swivel stand and can be cleaned in place.

3A certifed pumps feature over-molded diaphragms, a swivel stand and can be cleaned in place (CIP). These pumps are constructed with polished stainless steel and feature an oil-free air valve.