Hygienic Pumps

Precision-engineered hygienic pumps, AODD pumps, drum pumps and more, from across our Unibloc, Flotronic and Hygenitec brands. All UHT hygienic pump products are built with the highest quality construction for proven reliability in the most demanding environments.

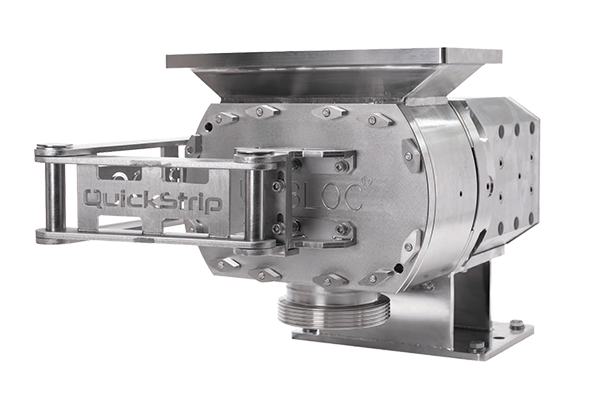

Unibloc®

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

Hygenitec™

Providing a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBCs). Constructed from stainless steel and designed with Tri-Clamp® fittings, these pumps can be disassembled quickly for cleaning.

Unibloc®

A completely hygienic, easy-to-clean pump is critical for pharmaceutical, biotech, and cannabis oil (CBD) applications. Our patented LABTOP pump series is simple and efficient with its “plug and go” design. This mobile solution is the perfect hygienic pump for filtration, chromatography, pilot applications, R&D and more.

Unibloc®

Designed for confined space applications in the food and beverage industries. Innovative, with easy mounting, pump motor alignment, smooth and quiet operation, and a small footprint.

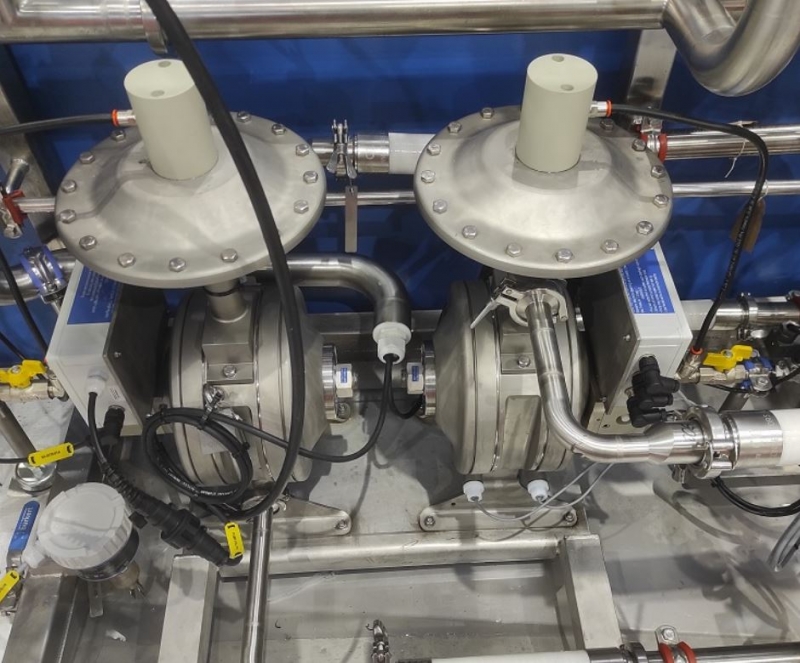

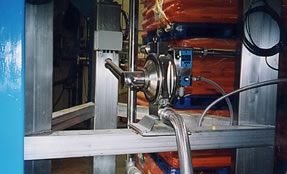

Flotronic®

Our barrel unloading systems combine our unique One-Nut hygienic/sanitary style AODD pump with our barrel unloading skid - allowing you to pump highly viscous materials at increased flow rates.

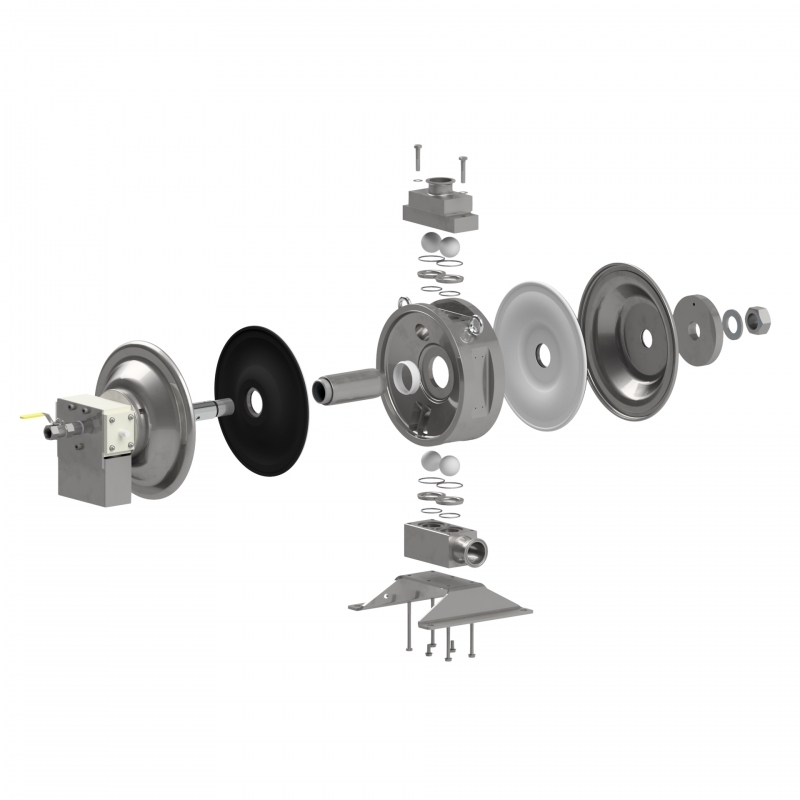

Flotronic®

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut Pump meets your application requirements.

Hygenitec™

Customize your sanitary drum pump with a selection of accessories, including discharge spouts, pump hangers, discharge hose, and Tri-Clamp® fittings.

Hygenitec™

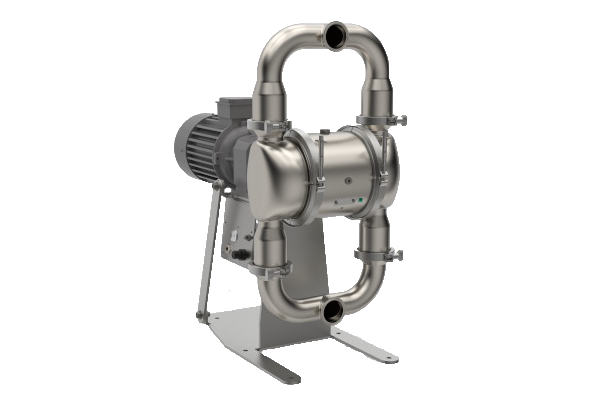

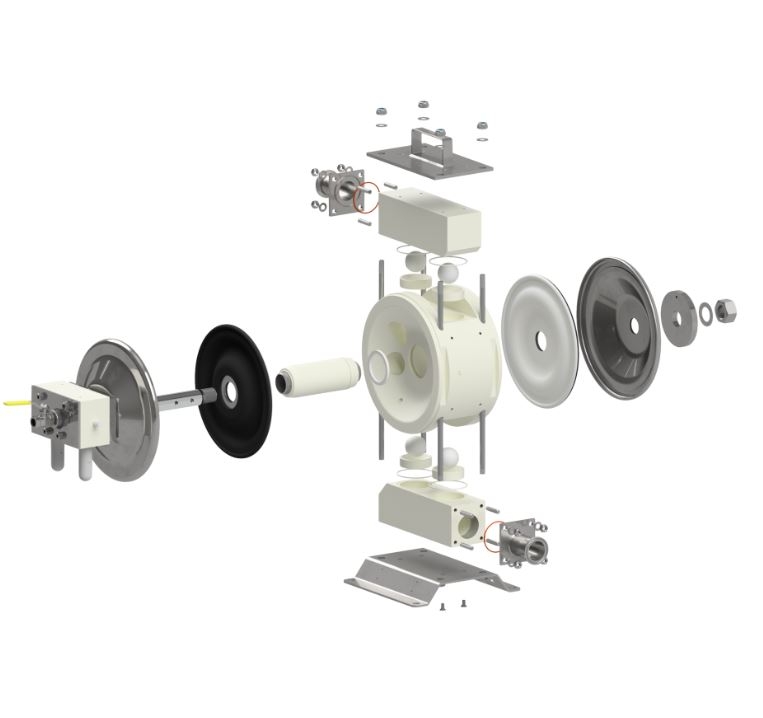

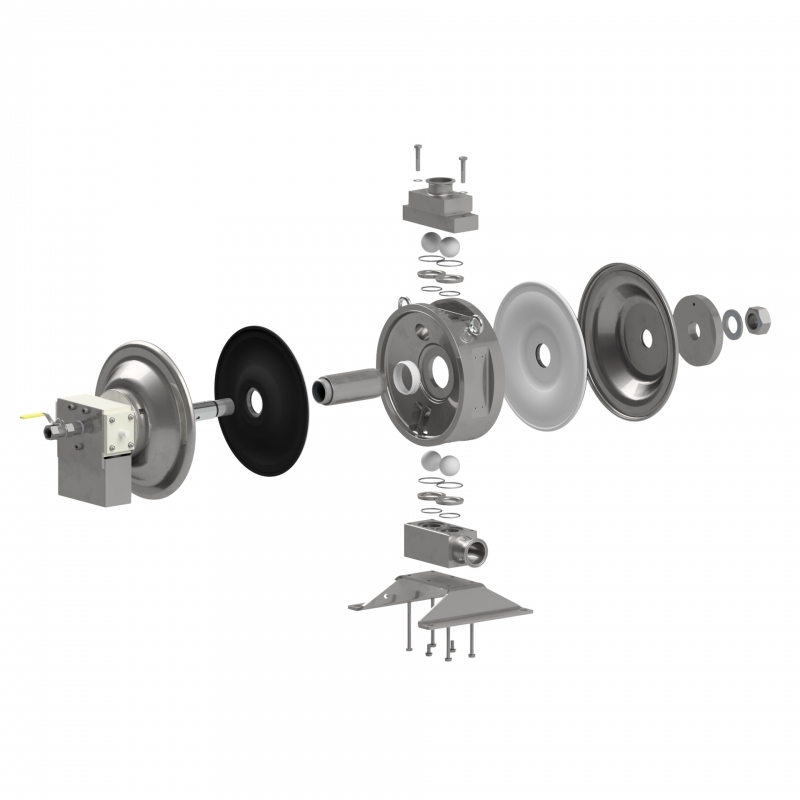

Electrically Operated Double Diaphragm Pumps

EODD pumps combine the advantages of an Air-Operated Double-Diaphragm Plus pump (AODD+) and the energy efficiency of an electric motor. EODD pumps can operate against a closed valve, run dry, and produce very little noise. Additionally, the pumps can operate in a low pulsation mode.

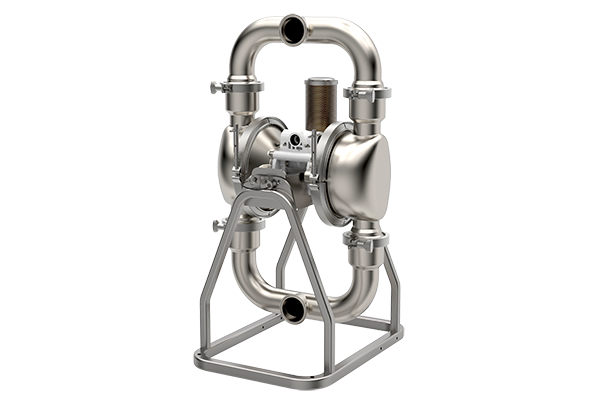

Hygenitec™

Air-Operated Double-Diaphragm Plus Pumps

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs. These pumps are fully drainable, machined from solid materials of stainless steel or Hastelloy® and are perfect for hygienic applications.

WHAT IS A SANITARY POSITIVE DISPLACEMENT PUMP?

A sanitary positive displacement (PD) pump moves fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms, or vanes.

Although there are quite a few pump options, the majority can be placed into two categories: reciprocating and rotary.

A Reciprocating Positive Displacement pump works by the cyclical strokes of either a piston, plunger, or diaphragm. Rotary positive displacement pumps use the continuous motion of gears to move fluids, rather than the backwards and forwards motion of reciprocating pumps. The rotating element develops a liquid seal with the pump casing and creates suction at the pump inlet. Fluid is drawn into the pump and then enclosed within the teeth of its rotating cogs or gears and transferred to the discharge. The simplest example of a rotary positive displacement pump is the gear pump.

From the Blog

View BlogWhy Flotronic® air-operated double-diaphragm pumps are so different we had to call them AODD+. Air-operated double-diaphragm pumps (AODD) pumps have been around since the 1950s. They are valued in a wide variety of applications because of their versatility. However, the proven, practical design of conventional AODD pumps has a significant drawback: they take too long to clean. Manually cleaning an AODD pump typically consumes two hours of labor or more.

Read BlogMeat Processing: Strategies for Reducing Maintenance Costs

The variety of available beef and pork products keeps increasing to meet consumers’ desire for convenience and choice. The more modern the processing facility is, the more plant managers and the industry can keep pace. Yet, automation is not as widespread as it seems, and, with budget constraints, companies must look for technologies that can improve their business operations in identifiable ways.

Read BlogHow Some Meat Processors Are Addressing Labor Issues Using Technology

Beef and pork processors have a lot on their plates. Not only must they keep down production costs, they have to do it while managing challenges posed by a scarce and low-skilled workforce. This blog post covers:

Read Blog