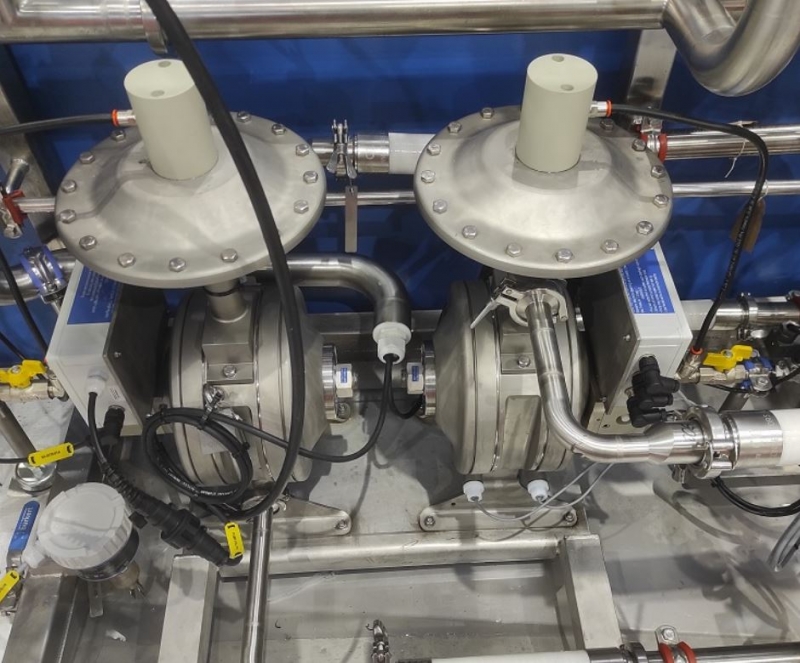

Diaphragm Pump For Pharmaceutical Skid

Flotronic provide Air-Operated Double-Diaphragm Pumps to a Pharmaceutical Skid Manufacturer for Clean Chemical Transfer Solutions.

A Global Skid Manufacturer required pumps with very specific application requirements to transfer chemicals in a Non-ATEX, clean area.

The requirement called for a chemically compatible pump, with rupture containment, electronic leak detection, auto shut off, and integral pulsation damper.

All of these features were required in a pump able to fit into a relatively small space, yet still able to supply sufficient flow rates for the transfer to take place successfully.

THE SOLUTION

Flotronic Pumps were able to provide 316L Stainless Steel Slimline AODD Pumps, with Guardian Rupture Containment .

Electronic Leak Detection sensors fitted within the Guardian Containment Chambers and connected to a Leak Detection Control Box; were installed to instantly detect any primary diaphragm rupture.

In the case of a diaphragm rupture, liquid is contained within the Guardian Chamber and a signal is given via the Leak Detection Control Box to a solenoid operated valve to shut down the air to the pump, stopping it instantly. This stops any possible contamination of the product, and stops any product from escaping from the pump.

In addition the integral Pulsation Damper removed pulsation from the lines, and a filter regulator to control and clean the air supply.

PUMP DETAILS:

- 316L Stainless Steel 1” Slim with Stainless Steel non-wetted parts, Triclamp flanges.

- Polypropylene air valve.

- Stainless Steel Guardian rupture containment.

- Electronic Leak Detection

- Auto shut-off valve (normally closed).

- Pulsation Dampener

- Filter regulator