Flotronic®– Pioneering the One-Nut® Sanitary Air-Operated Double-Diaphragm Plus

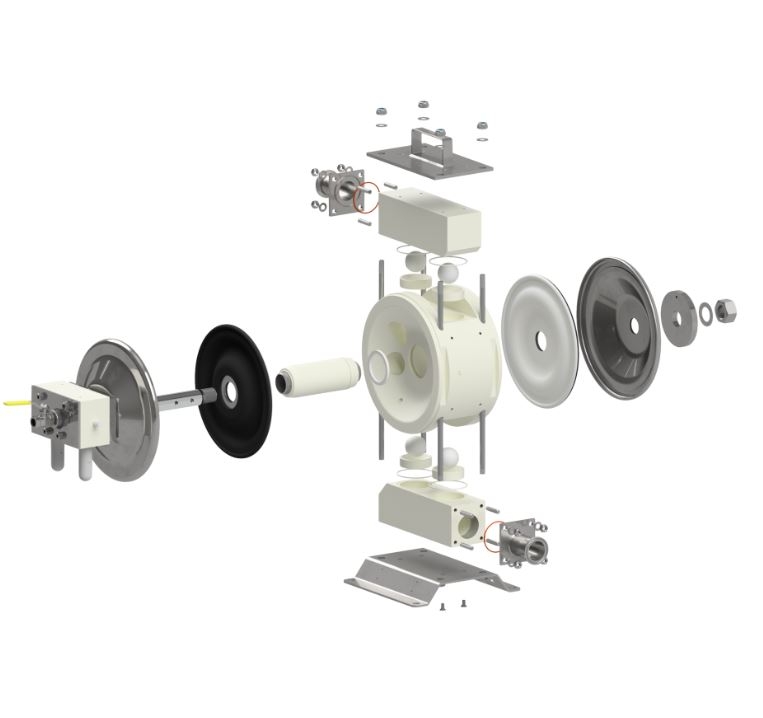

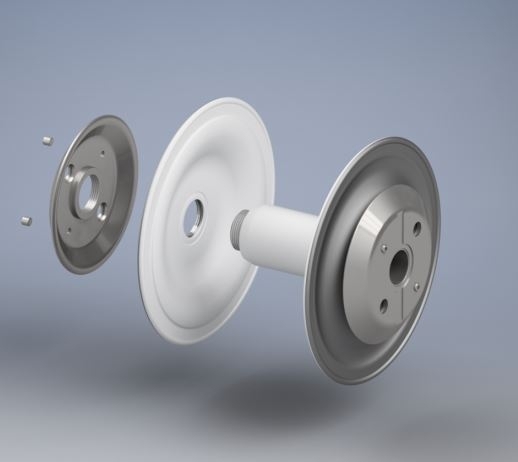

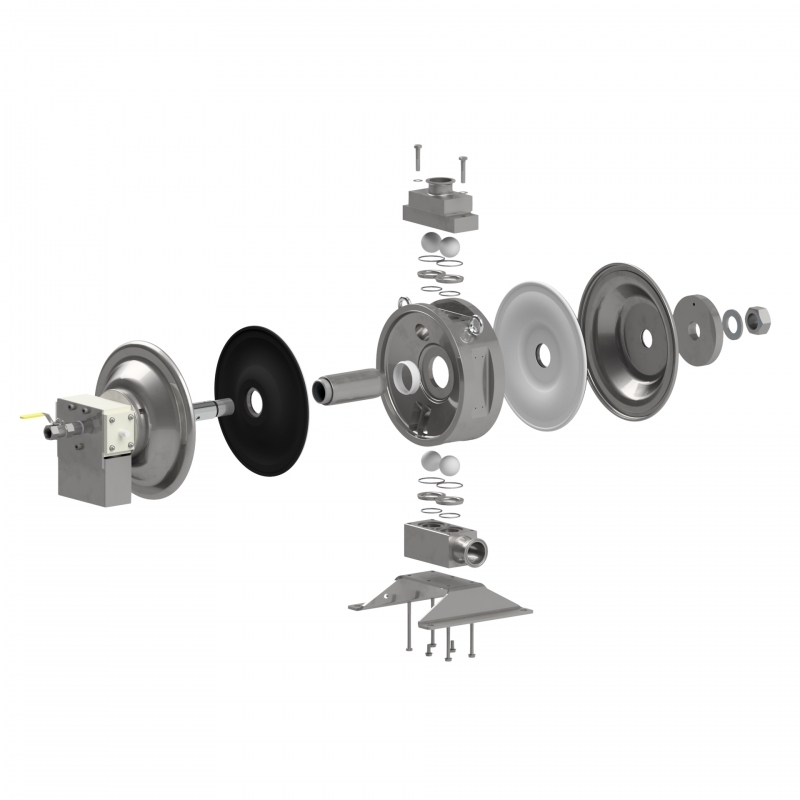

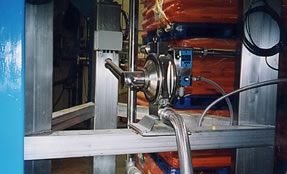

Flotronic® has made its name by developing its unique product, the One-Nut® Air-Operated Double-Diaphragm Plus (AODD+). This pioneering design offers swift disassembly without disconnecting the pump from the process pipework.

Flotronic® One-Nut pumps can transfer a wide range of materials of varying degrees of viscosity and solids content. They can pump chemicals, adhesives, cosmetics, drinks, dyes, foodstuff, paints, pharmaceuticals and solvents. Our clients’ products are extremely diverse, ranging from industrial acids to hand creams and various food products.

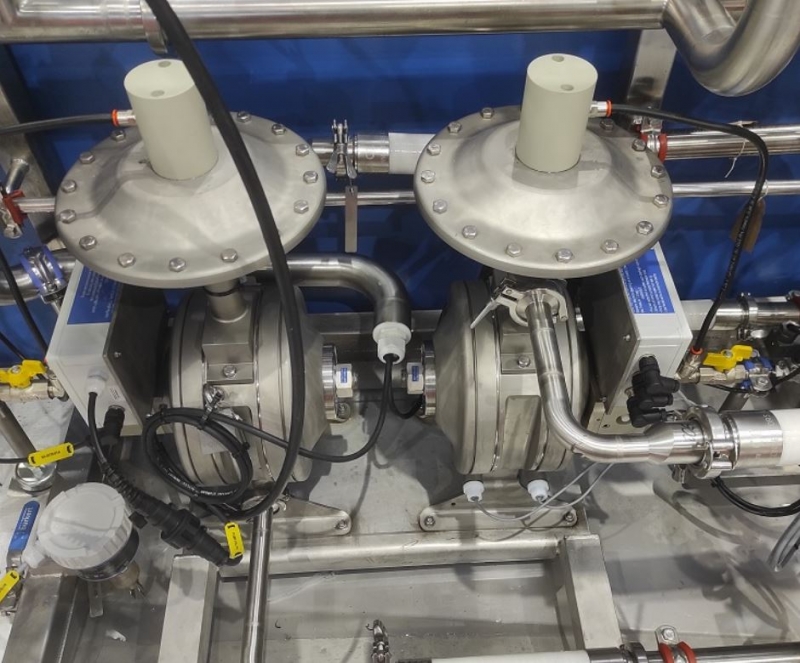

Flotronic® Barrel Unloading System

The Flotronic Barrel Unloading System combines our unique One Nut Sanitary Air-Operated Double-Diaphragm Pump with our Barrel Unloading Skid; perfect for high viscosities.

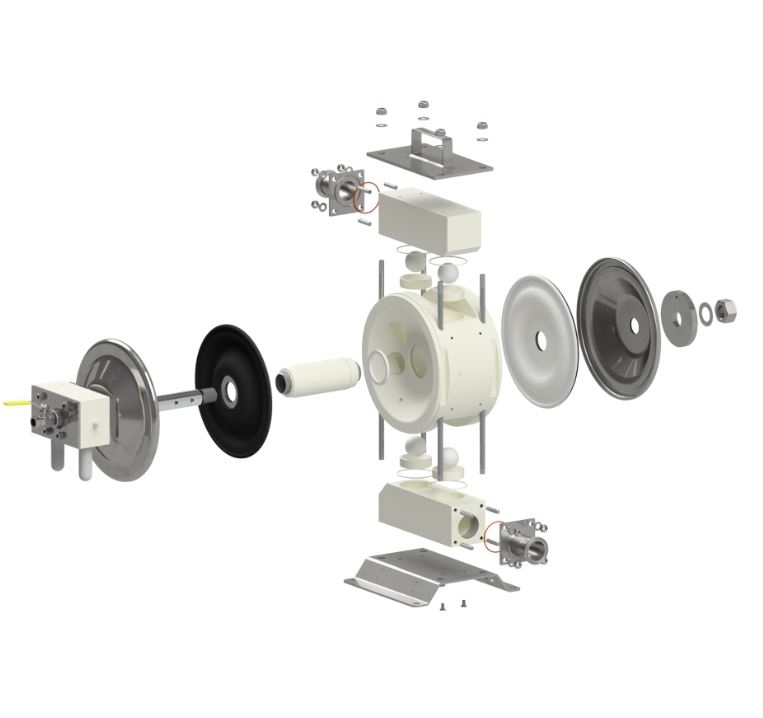

FDA Compliant PTFE AODD Pump machined from a solid block of Virgin or anti-static PTFE, housed completely inside a stainless steel casing, providing safe transfer of your hazardous liquids.

The Minichem is a totally unique design of FDA Compliant PTFE Double Diaphragm Pump machined from one solid block of PTFE, removing the need for separate manifolds.

Flotronic® 500 Series Plastic Pump

Unique Polypropylene / PVC plastic Double Diaphragm Pump design normally used for pumping / transferring solvents, acid or chemicals, often as a low cost option to stainless steel.

Flotronic® One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut pump meets your application requirements.

Flotronic® Sanitary AODD+ Pump

Designed with 3A in mind using FDA, USP Class VI and (EC) 1935/2004 approved materials; our range of Sanitary Diaphragm Pumps help maintain and improve hygienic conditions on your site.

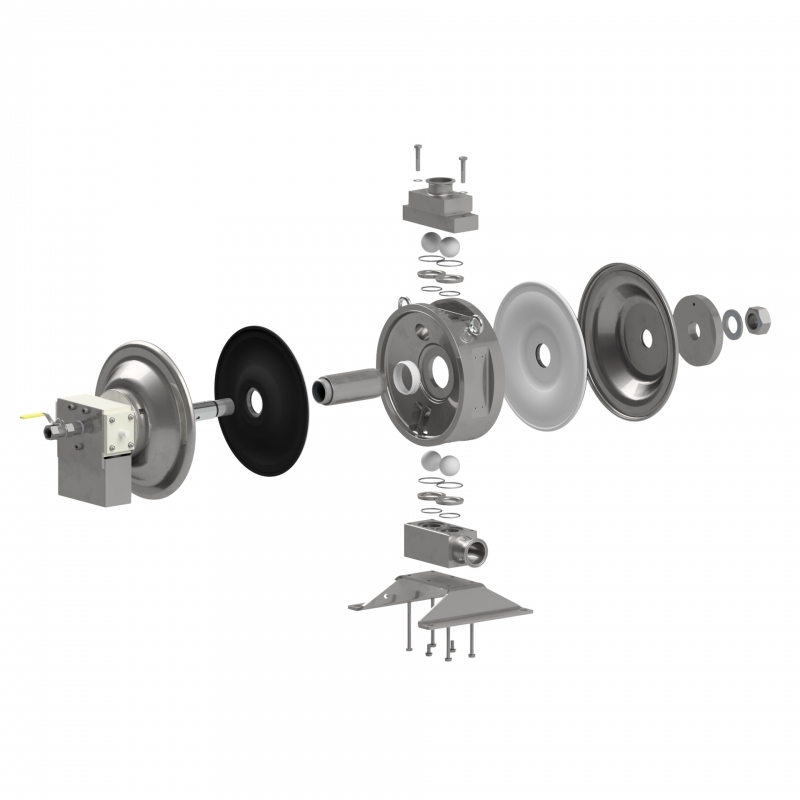

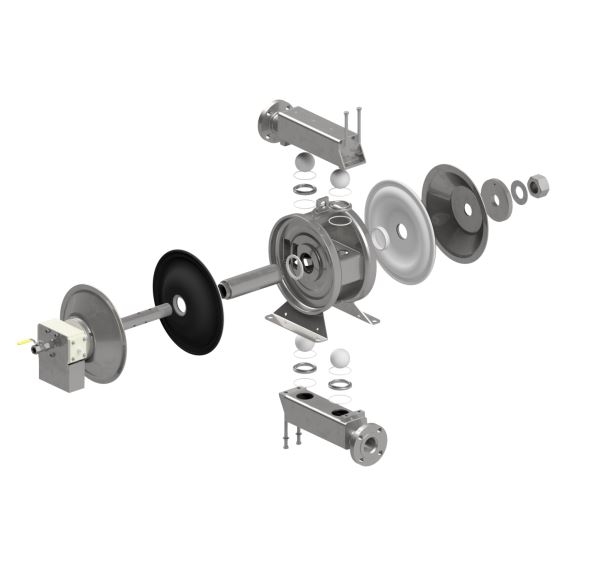

Flotronic® 710 Series Stainless Steel Pump

Fabricated 316L stainless steel or Hastelloy® on all wetted metal parts offers unrivaled versatility. These FDA compliant Air-Operated Double-Diaphragm Pumps are used extensively throughout the industry.

A compact and self-draining Diaphragm Pump available in FDA approved 316L stainless steel, aluminium, Duplex 22, and Hastelloy®; used in an array of industries.

Flotronic® Good Food Pump- Food Grade AODD Pump

Double Diaphragm Pump ideal for pumping your food products, especially on high viscosity low shear applications. Designed for ‘quick strip’ which is tool free or the pumps can be ‘cleaned in place’ (CIP), manufactured throughout from FDA compliant approved materials. The 'Good Food' pump gives food industry customers very specific benefits.

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Supplying Sanitary AODD+ Pumps to Industries Worldwide

The pioneering sanitary One-Nut Air-Operated Double-Diaphragm Plus (AODD+) pumps changed the industry by providing:

- Reduced downtime through simplified assembly/disassembly

- Savings in easier maintenance and increased performance

- Best-in-class, when Clean-in-place is a requirement

- Easy / quick maintenance

- Self-draining

- 60% less product left in the pump than any competitor AODD pump, for reduced waste and more efficient cleaning

- Ability to CIP or SIP (steam in place) at up to 7Bar / 100 psi

UHT engineers can provide bespoke pumping solutions to meet your needs, with applications experts working together with you to put the right solution into your production facility.

Quick Links

From the Blog

View BlogWhy Flotronic® air-operated double-diaphragm pumps are so different we had to call them AODD+. Air-operated double-diaphragm pumps (AODD) pumps have been around since the 1950s. They are valued in a wide variety of applications because of their versatility. However, the proven, practical design of conventional AODD pumps has a significant drawback: they take too long to clean. Manually cleaning an AODD pump typically consumes two hours of labor or more.

Read BlogMeat Processing: Strategies for Reducing Maintenance Costs

The variety of available beef and pork products keeps increasing to meet consumers’ desire for convenience and choice. The more modern the processing facility is, the more plant managers and the industry can keep pace. Yet, automation is not as widespread as it seems, and, with budget constraints, companies must look for technologies that can improve their business operations in identifiable ways.

Read BlogHow Some Meat Processors Are Addressing Labor Issues Using Technology

Beef and pork processors have a lot on their plates. Not only must they keep down production costs, they have to do it while managing challenges posed by a scarce and low-skilled workforce. This blog post covers:

Read Blog