At this plant, Unibloc® QuickStrip® FoodFirst® 600 Series pumps minimized contamination risk, simplified maintenance, and reduced sanitation time

Read Case StudyTo help food processors meet consumer demands, MP Equipment, Gainesville, GA, provides automated breading and batter coating equipment to the meat, poultry, seafood, and alternative protein processing industry.

Read Case StudyFood processors are challenged to find pumps that meet their requirements for hygienic concerns, ease-of-maintenance and high temperatures. Read how this automated frying equipment OEM solved all of those issues.

Read Case StudyOakley Transport solves seal and pump failure issues with Unibloc pumps - keeping this hauler of liquid food-grade cargo on the road.

Read Case StudyThe QuickStrip FoodFirst pump increased uptime and reduced potential foreign material issues in an application no other pump could handle.

Read Case StudyA chemical manufacturer based in the US required a mobile cleaning skid; to be used on their plant, in the production of intermediate chemicals, for flavors, fragrances, cosmetics, aroma

Read Case StudyA Multi-National manufacturer of Flavoured Iced Tea and Soft Drinks required a solution to their flavour distribution pumps. The area was plagued by unreliable pumps and an intensive

Read Case StudyA major pharmaceutical manufacturer in Dublin, Ireland came to Flotronic Pumps looking for a pumping solution. The application was to decant chemicals safely from 220 litre containers into

Read Case StudyA leading Global Pharmaceutical company took on a project to modernise the taking of samples from reactors. In order to do this they required a bespoke pump which

Read Case StudyAODD PUMP FOR OEM SERVICING THE SNACK FOOD INDUSTRY Snack Engineering is a company based in Northern Ireland who offer specialist support and bespoke machinery mainly to

Read Case StudyA Japanese food manufacturer transferring Kimchi Sauce with Rotary Pumps were having a problem with stainless steel particles caused by stainless steel friction within their Rotary Pump. Metal detectors

Read Case StudyA French Confectionary manufacturer needed to transfer Warm Chocolate containing Whole Almonds. Obvious concerns were the Viscosity of the Chocolate at 6,000Cps, Whole Almonds at up to 13mm and a

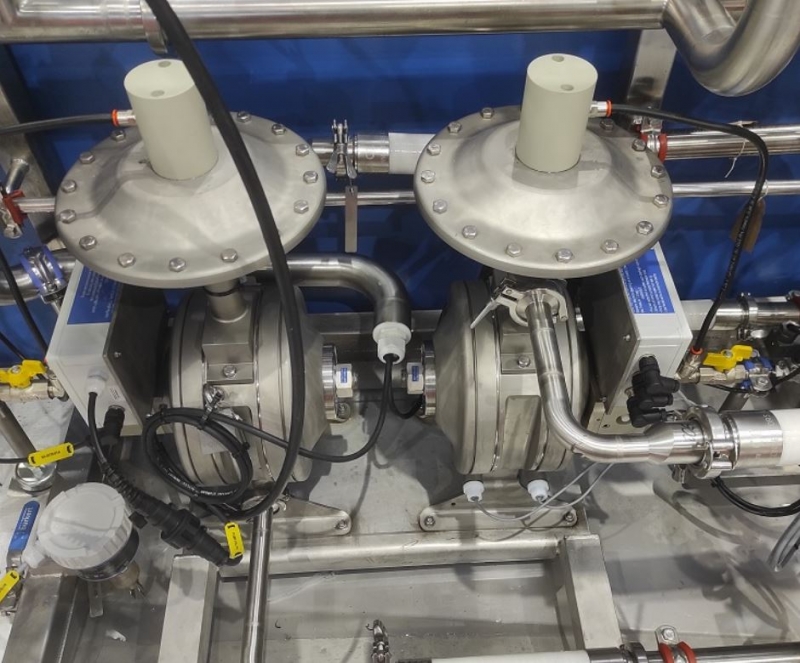

Read Case StudyFlotronic provide Air-Operated Double-Diaphragm Pumps to a Pharmaceutical Skid Manufacturer for Clean Chemical Transfer Solutions. A Global Skid Manufacturer required pumps with very specific application requirements to transfer chemicals in a

Read Case StudyA Skid manufacturer based in the USA, working on behalf of a major Pharmaceutical Manufacturor of a COVID-19 Vaccine, required very reliable pumps on an application pumping CIP chemicals

Read Case StudyA major producer of flavours and fragrances in Germany was faced with problems controlling their flow rates caused by the electric-driven pumps that were being used on their filling machines.

Read Case StudyAn International Car Manufacturer needed to Pump Sulphuric Acid at one of their plants in the UK. Obviously this material needed to transferred safely; with pump longevity and the time between

Read Case StudyA Global Personal Care manufacturer required a Sanitary Double Diaphragm Pump to add a food grade ingredient to its process at a very low flow rate. The problem was that

Read Case StudyA Food manufacturer in the UK needed to pump Tomato pieces / purees from 220 ltr 'Bag in a Drum' barrels. The pump needed to be self priming, even on

Read Case StudyFlotronic‘s unique 'One Nut' sanitary style AODP is being utilised by a major UK food manufacturer in the transportation of flavoured waters and oils to their food products

Read Case StudyA prestigious automotive manufacturing plant in the UK required specialist pumps for safely transferring a variety of liquids including but not limited to petrol, diesel and

Read Case StudyA personal care intermediate chemical manufacturer in the USA had an issue pumping a chemical that goes off at ambient temperatures, tending to solidify if left to go cold.

Read Case StudyInternational specialty chemical manufacturer needed to pump ethanol from road tankers into their storage tanks. The Flotronic 710 range of 316L stainless steel Air-Operated Double-Diaphragm Pump is perfect for this

Read Case StudyAn international producer of flexible printed packaging needed to pump solvents safely at one of their plants in the UK. The pumps were needed in an ATEX rated area, and

Read Case StudyEuropean ready meal manufacturer were having problems with incorrect weights of product going into their mixing vessels at one of their 3 plants in the UK. One of the accessories available

Read Case StudyAn international specialist chemical manufacturer; branching out into the production of bulk hand sanitizer needed an hygienic pump that was able to keep up with their production requirements, and deliver

Read Case StudyInternational Paint manufacturer with plants in Europe was having problems with standard AODP due to thermal expansion in pipelines outside the factory. Product was being heated up in the pipelines

Read Case StudyA global contract personal care manufacturer with plants based in the UK are using the Flotronic 'One Nut' sanitary style Air-Operated Double-Diaphragm pump, to pump their full range of personal

Read Case StudyInternational aerosol filler / manufacturer with plants all over Europe needed ATEX certified pumps to pump acetone from IBCs to volumetric filling heads. Their existing piston pump suffered from constant

Read Case StudyOne of the Top 10 decorative paint manufacturers in the World, needed to pump water based decorative paints from their storage tanks to filling lines at one of their plants

Read Case StudyWhen an international Personal / Household care manufacturer needed sanitary Air-Operated Double-Diaphragm pumps for its manufacturing plant based in Hungary; Flotronic were happy to provide one of their

Read Case StudyUK based personal care products manufacturer need to ramp up its hand sanitiser production line. Flotronic were able to supply one of their Sanitary style 316L stainless steel range of

Read Case StudyA global soft drinks manufacturing company – for whom Flotronic Pumps Ltd are the preferred Air-Operated Double-Diaphragm pump supplier – came to Flotronic with a non-Air-Operated Diaphragm Pump

Read Case StudyInternational active pharmaceutical ingredients (API) manufacturing company with plants based in the Republic of Ireland were having problems with tubular diaphragm Pumps. Tubes would fail meaning that oil was able

Read Case StudyLeading contract cosmetics manufacturer based in the UK working with many of the leading Global health and beauty brands, needed a reliable and safe method for pumping the many and

Read Case StudyUnited Stated based pharmaceutical ingredient manufacturer in Rochester, NY had severe issues pumping a zinc oxide / water slurry. The traditional AODD design pump was being overhauled or replaced a minimum

Read Case StudyUK based quilt and pillow makers based in relies upon several Air-Operated Double-Diaphragm Pumps from FPL in their production processes. The company uses 20 million kgs of feathers and 10 million

Read Case StudyWhen an International Adhesive manufacturer needed to increase their flow of adhesive they turned to their supplier of Air-Operated Double-Diaphragm pumps. For over six years thier "One Nut" fast maintenance AODD

Read Case StudyFor over four years now, a UK Based Brewery have been using two Air-Operated Diaphragm Pumps from Flotronic Pumps Limited to transfer yeast at different stages of their brewing process.

Read Case StudyWorld leading paint manufacturer needed to improve their tanker offloading of Acrylic Acid. Having used Flotronic Air-Operated Double-Diaphragm Pumps for many years throughout their site, they asked if Flotronic

Read Case StudyA UK sauce manufacturer who is a supplier to one of the world's most popular fast food chains, has been able to speed up its filling process using a fast maintenance,

Read Case StudyUK based laboratory with expertise in the development and manufacture of branded products for the pharmaceutical, toiletry and household markets. Specialising in liquids, lotions, creams, gels, suspensions and alcohol-based formulations;

Read Case StudyA ready made salad manufacturer based in the UK were having problems pumping their mayonnaise and after trying both progressing cavity and air operated stick pumps they turned to Flotronic

Read Case StudyUK based manufacturers of industrial cleaning and maintenance chemicals have been using the Flotronic 'One Nut' Air-Operated Double-Diaphragm Pump for nearly twelve years at the heart of their process. Three

Read Case StudyAfter replacing their older style 'figure of eight' AODP which regularly failed, with Flotronic 'One Nut' pumps, they have almost forgotten they are there. The Flotronic Air-Operated Double-Diaphragm pumps have

Read Case StudyIt is well known that Air-Operated Double-Diaphragm pumps are often specified in the chemical industry where explosive/flammable environments exist, but less commonly known in alcoholic drinks production. But not

Read Case StudyA renowned UK producer of luxury bathing products, some years ago switched from electrically driven pumps to the unique 'One Nut' fast maintenance double diaphragm pumps from FPL and saved both time

Read Case StudyLeading soft drinks manufacturer based in the UK needed to speed up their concentrates pumping so turned to Flotronic Pumps and following a successful trial purchased a number of their

Read Case StudyOne of the UK’s leading manufacturer of pies and sausages, with factories in Nottingham and Trowbridge purchased two Good Food Pumps from Flotronic Pumps Ltd and have saved a significant

Read Case StudyUSA owned flavourings company based in the UK, relies upon Hygienic Air-Operated Double-Diaphragm Pumps from FPL in the production of speciality flavours, used in the food and pharmaceutical

Read Case StudyBritish speciality chemical manufacturer has streamlined its blending operations – and reduced downtime - using six 710 series Hiflo Double Diaphragm Pumps from Flotronic Pumps Ltd. The media being pumped ranges from

Read Case StudyOne of the worlds leading fragrances, flavours and food ingredients companies are using the Flotronic Air-Operated Double-Diaphragm Pumps as their site standard, replacing the older style 'figure of

Read Case StudyAs a result of seeing an advert for the 'One Nut' AODP from Flotronic Pumps Ltd, an international essential oils manufacturer based in the UK were impressed with the simplicity of

Read Case StudyWell know pizza manufacturing company were planning their new pizza factory in the UK, they turned to Flotronic Pumps to pump their range of tomato toppings and as a result have

Read Case StudyWhen an international toothpaste manufacturer needed to expand and upgrade their toothpaste flavour dosing system they turned to Flotronic Pumps. Due to increasing customer choice the number of flavours had steadily

Read Case StudyZotefoams PLC manufacture a range of closed cell crosslinked polyolefin foams using a unique, environmentally friendly, nitrogen expansion process. Switching from traditional designed double diaphragm pumps to the 'One Nut' fast

Read Case StudyWhen Schefenacker Vision Systems UK Ltd, a major producer of car door mirrors, were looking to improve their Paint Kitchen they trialed a "One Nut" Air-Operated Double-Diaphragm Pump

Read Case StudyUK based manufacturer of speciality chemicals has reduced its pump maintenance time from half a day to less than half an hour, using a 'one nut', polypropylene Air Operated Double

Read Case StudyUK leading cereal bar producers has recently expanded their production of cereal bars by investing in a new production facility at a cost of between Euro 5 and 6 million

Read Case StudyFour years and no maintenance required. Yes that’s what one specialist coatings manufacturer has found since installing the Flotronic 500 Series ‘One Nut’ Double Diaphragm Pump. A specialist manufacturer of coatings to the

Read Case StudyUK based creamery replacing older style diaphragm pumps with their "One Nut" quick maintenance pump, Flotronic Air-Operated Double-Diaphragm Pumps are used for pumping caustic and nitric acid as

Read Case StudyWhen Klockner Pentapack switched from drums to pallecons they reviewed their pumping needs. Previously they had been using air operated piston drum pumps but the switch to pallecons enabled them to

Read Case StudyFor over five years 'One Nut' Air-Operated Double-Diaphragm Pumps from Flotronic have been working reliably in the medicated confectionery plant, requiring minimal servicing. A top end contract manufacturer supplying shops in almost

Read Case StudyA leading soft drinks manufacturer had a serious problem with pipework pulsation from a rotary lobe pump, resulting in pipes being ripped from their supports and a fracture to an

Read Case StudySunjuice Ltd, part of the Jamaica Producers Group, is the European market leader in freshly squeezed juices, crushes and smoothies. Essential to their success has been the importance of supplying

Read Case StudyAn international, food processor needed a hygienic AODP for the production lines at one of their sauce production plants based in the North of the UK Flotronic was able to supply two of their

Read Case StudyAs their business grows, SIAS Foods (UK) Ltd realised that they needed to improve their handling of fruit pulps, when they saw an advert for the Good Food Pump from Flotronic.

Read Case StudyA leading supplier of specialty chemicals, turned to Flotronic when they had to transfer a 'dense' chemical with an SG of over 2.0 as the existing AODD pumps could not cope.

Read Case StudyWhen Sutton & Son (St Helens) Ltd were looking for a mobile pump to fit on their Emergency Response Units, following a successful trial, they settled on the Chemflo all

Read Case StudyThe customer, a specialty chemical manufacturer in the Midlands, produce a range of specialty products destined for a variety of applications including: surface finishing processes for the automotive, aerospace, telecommunications,

Read Case StudyWhen Revage Cosmetics, a contract manufacturer in Horley were faced with pumping a Dead Sea Mud they first tried progressing cavity, peristaltic and piston pumps without success.

Read Case StudyOh no! There are no results matching this filter combination.

Try another filter combination, or .