Hygienic Double Diaphragm Pump Transferring Essential Oils

As a result of seeing an advert for the 'One Nut' AODP from Flotronic Pumps Ltd, an international essential oils manufacturer based in the UK were impressed with the simplicity of the design and purchased two of their new award winning slimline FDA approved Hygienic Double Diaphragm Pumps to handle Terpenes.

Manufacturing natural concentrated oils, steam distilled oils, alcoholic extracts, flavours, oleoresins and dispersed herb and spice extracts. The company is a leading supplier to the food, beverage, toiletry and cosmetic industries as well as the flavour and fragrance houses.

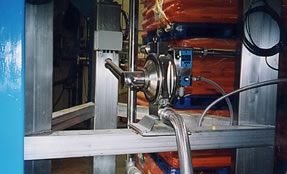

Because of the success of the first two hygienic pumps, they purchased a further FPL 1½" Slimline 316 Stainless Steel AODD pump fitted with virgin PTFE diaphragms to load liquid raw material and flavourings into a steam heated mixing vessel.

Sucking either from 1000 litres IBC’s or 200 litre drums with a lift of 1.5 metres, the media is then pumped into the top of the mixing vessel, a height of 4 metres. The viscosity is typically around 500 cp’s at ambient temperature.

The pump is fitted with a batch counter which regulates the number of pump cycles to achieve pre-determined quantities of product. Cleaning is critical, so the new slimline diaphragm pumps are ideally suited because they are machined from solid 316 Stainless Steel, with no welds and designed to be self draining, which reduces product residue. They have no ball valve seats, resulting in a more hygienic Crevice-fee design.

"Flotronic Pumps were selected" comments - Engineering Manager "because I like the ease of stripping, they have food industry approval, were competitive and are of UK manufacture."

PROCESS DETAILS

- Raw materials & flavourings

- Viscosity 500 cps

- 1.5 m lift

- Ambient temperature

PUMP DETAILS

- 1½" Slimline 316 stainless steel

- PTFE elastomers

- RJT Connections