Beauty and Personal Care

The beauty and personal care industry thrives on luxurious textures but achieving them can be a complex process. Selecting the right processing equipment, especially pumps for transferring raw materials from IBC containers to delicate final containers requires careful consideration.Cosmetics, beauty products, skincare products, and healthcare creams and ointments can be highly viscous, making them difficult to pump. Yet, the pumping must be gentle to retain the integrity of shear-sensitive products. Suspended particles, as well, must not be damaged by pumping. Some beauty products contain ingredients that are abrasive, potentially causing excessive wear.

This industry is characterized by short runs, frequent batch changes, and frequent cleaning of pumps and storage containers. Given the amount of cleaning required, managers prefer pumps that can be cleaned in place or cleaned quickly if manual cleaning is necessary.

Beauty and personal care products tend to have a high value per ounce. The less product remaining in the pump between batches, equals less waste.

We offer pumps designed to face these challenges.

Frequent cleaning

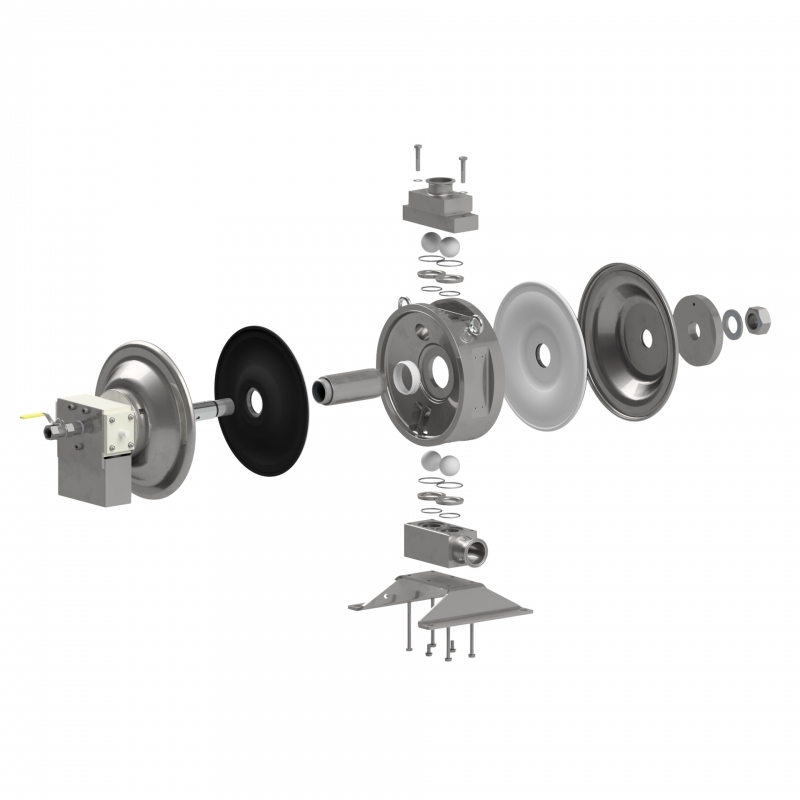

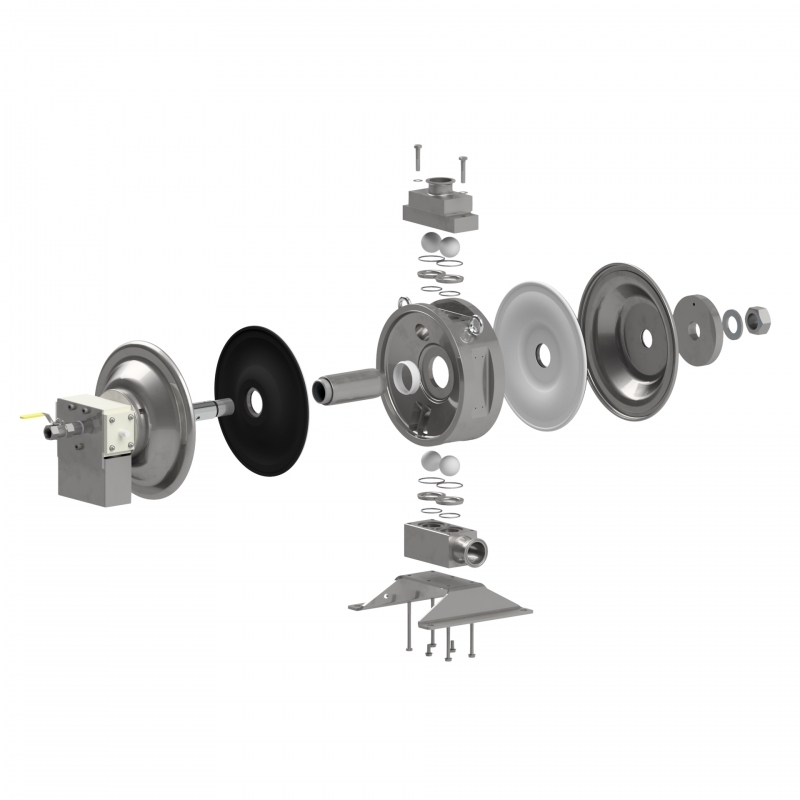

Flotronic® One-Nut® AODD pumps are CIP-able and fully self-draining—no waste of valuable product. In COP applications, the pump can be disassembled by removing one nut. This unique design slashes cleaning time to 15 minutes and offers 60% less wasted product than other designs.

Unibloc® lobe pumps are CIP-able and easy to clean via COP. With tool-free disassembly, fewer parts, and one-way part assembly, technicians can clean the pump with little training. Cleaning takes 20 minutes instead of an hour, freeing up labor for other tasks.

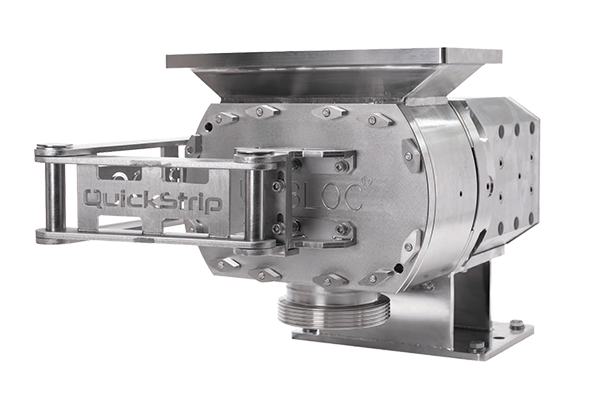

CleanPlus™ lobe pumps offer bolt-free rotors that avoid the damage caused by improperly torqued rotor bolts. Their stainless-steel rotors eliminate the possibility of contamination from plastic wearing into the product. Best of all, the QuickStrip® design dramatically slashes the time required for Clean-out-of-Place (COP) cycles. By the way, the patented FlushCap bearing makes CleanPlus pumps fully compatible with Clean-in-Place (CIP) processes.

High viscosity

Hygenitec® positive displacement drum pumps can transfer viscous products up to 500,000 cPs. The Flotronic AODD pumps are also capable of pumping products up to 500,000. Unibloc lobe pumps can transfer products up to 1,000,000 cPs.

Abrasion

Flotronic AODD pumps can transfer products containing particles up to 25mm cube. Unibloc lobe pumps are available with steel rotors that are abrasion resistant.

Product integrity

Unlike centrifugal pumps, our AODD, lobe, and drum positive-displacement pumps are ideal for shear-sensitive products.

Hygienic

Our company specializes in hygienic pumps that are certified FDA-compliant for pharmaceutical and food-grade applications. Our lobe pumps use crevice-free housings and have fewer dead spots than some competing designs.

From the Blog

Highlighting Flotronic® Slimline Pump Advantages: Unique Features Rise Above the Competition

Introducing the Flotronic® 14-Inch Slimline Pump: Handle Greater Volume and Higher Viscosities

5 Industries That Benefit From AODD Pumps

Upcoming Events

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Explore Solutions

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

Providing a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBCs). Constructed from stainless steel and designed with Tri-Clamp® fittings, these pumps can be disassembled quickly for cleaning.

Designed for confined space applications in the food and beverage industries. Innovative, with easy mounting, pump motor alignment, smooth and quiet operation, and a small footprint.

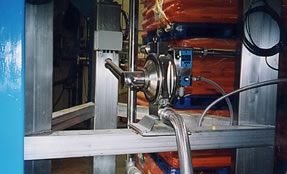

Our barrel unloading systems combine our unique One-Nut hygienic/sanitary style AODD pump with our barrel unloading skid - allowing you to pump highly viscous materials at increased flow rates.

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut Pump meets your application requirements.

Customize your sanitary drum pump with a selection of accessories, including discharge spouts, pump hangers, discharge hose, and Tri-Clamp® fittings.

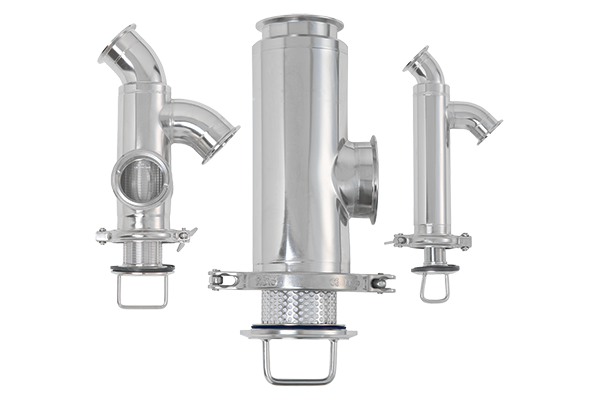

Engineered to remove pockets of air during the critical chromatography processes, our hygienic bubble traps feature an ultra-clean and installation-friendly design. We offer a wide array of sizes and port configurations.

Sanitary sight glasses, available in various sizes, glass materials and pressure ranges, give you extra efficiency and protection while supervising your active process.

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of sanitary strainers in both standard and high capacity configurations.

View a complete selection of sanitary valves including pressure relief valves, check valves and butterfly valves.

Air-Operated Double-Diaphragm Plus Pumps

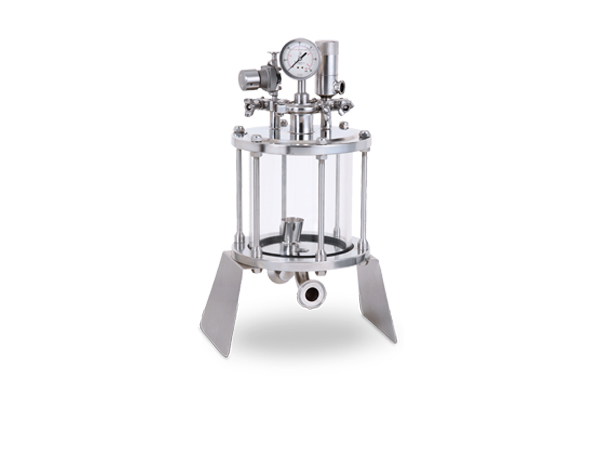

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs. These pumps are fully drainable, machined from solid materials of stainless steel or Hastelloy® and are perfect for hygienic applications.