Diaphragm Pump for Hand Sanitiser Production

UK based personal care products manufacturer need to ramp up its hand sanitiser production line. Flotronic were able to supply one of their Sanitary style 316L stainless steel range of pumps on a 'next day' delivery, due to the commitment of it's UK based production / manufacturing team.

Pumps used to transfer raw product into mixing vessels, where they are then used to recirculate the product aiding the mixing process. Also used to pump the finished Hand Sanitiser from mixing vessel to pallet ready for transfer to the filling lines.

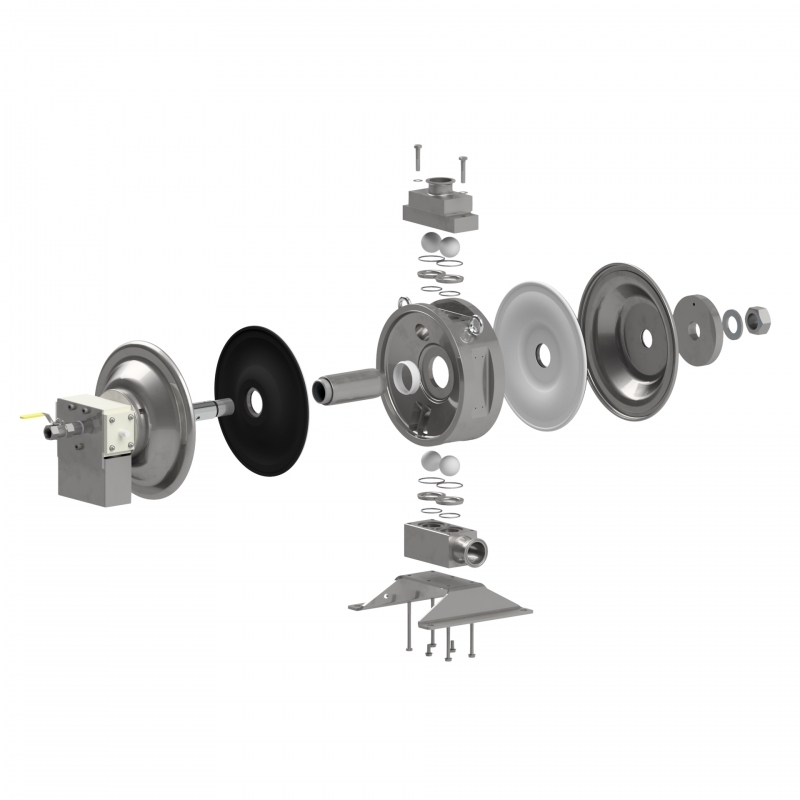

Flotronics unique 'One Nut' design of sanitary style air operated pump was especially important to this user, because of the ease of cleaning and less product hold up, this design of AODP offers.

BENEFITS

- Fully FDA.

- (EU) 1935/2004 approved materials used.

- Sanitary features & Benefits

- Fully CIP

- Ability to fully drain the pump after any CIP cycle without the need to take the pump out of line, no manual intervention required.

- Fully Drainable

- ATEX rated for flammable liquid transfer.

- Fast strip while pumps in-line to inspect.

- 70% less product hold up than traditional Air-Operated Diaphragm Pumps.

- Self Priming - up to 0.8 bar Vacuum.

PROCESS DETAILS

- Used in the transfer of raw material to mixing vessel.

- Recirculating to aid with mixing process.

- Pumping finished product to pallet for transfer to filling lines.

PUMP DETAILS

- Pump Code: F27SSTT6SRJTOR

- Sanitary Style 316L.

- 2" RJT connections

- Max Flow: 450 ltr/min