Food Processing Pumps

Our hygienic pumps excel in food processing and provides many benefits from CIP and COP capability, compact design, mounting versatility and more.Pumps used in the food processing industry ultimately must meet two standards:

- Separate the product from the mechanical elements that move the product.

- Maintain the integrity of the processed product.

Each food pump variation accommodates these challenges differently. Likewise, individual sectors prefer a specific pump type and design that suits their processing needs. Unibloc Hygienic Technologies makes a pump to fit your application and meet your processing requirements. The food processing industry works with a diverse, often expensive range of ingredients, which requires highly controlled pumping and transportation. Many product components are of particularly high viscosity and often include abrasive additives and solid particulates. In addition to this, the requirement to comply with FDA & (EC) 1935/2004 regulations makes selecting the right equipment imperative.

Features and Benefits

Our sanitary pump excels in the food processing industry and provides many benefits:

- Flat, crevice-free front cover that eliminates product dead zones

- CIP and COP capability with easy Strip-down and cleaning

- Compact, unique and shear design

- Horizontal or vertical mounting versatility

- Eliminates pump and motor alignment issues

- Safe design with no accessible moving parts

- Ability to disassemble and clean pumps

- Products feature Tri-Clamps and simple designs to aid the disassembly process

- High Viscosity, including barrel unloading systems that can support high viscosity applications

- Self-draining

- FDA-compliant and hygienic versions of all pumps available

From the Blog

Control Your Plant’s Destiny—FDA-Compliant Pumps Can Aid Food Safety

Maintenance Made Easy with the Unibloc® UltraLobe™ FoodFirst 700 Series

How the Unibloc® UltraLobe™ FoodFirst 700 Series Pump Ensures Safe and Clean Fluid Handling

Upcoming Events

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Explore Solutions

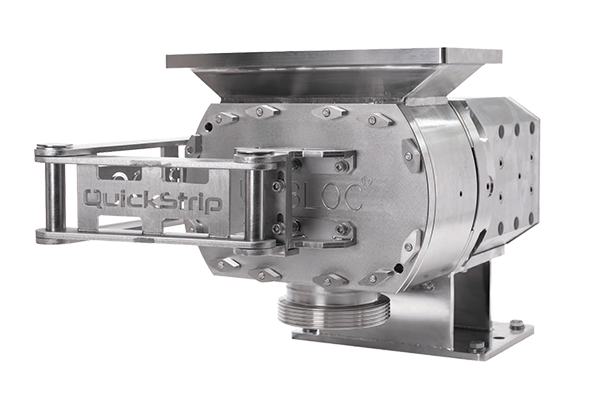

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

Providing a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBCs). Constructed from stainless steel and designed with Tri-Clamp® fittings, these pumps can be disassembled quickly for cleaning.

Designed for confined space applications in the food and beverage industries. Innovative, with easy mounting, pump motor alignment, smooth and quiet operation, and a small footprint.

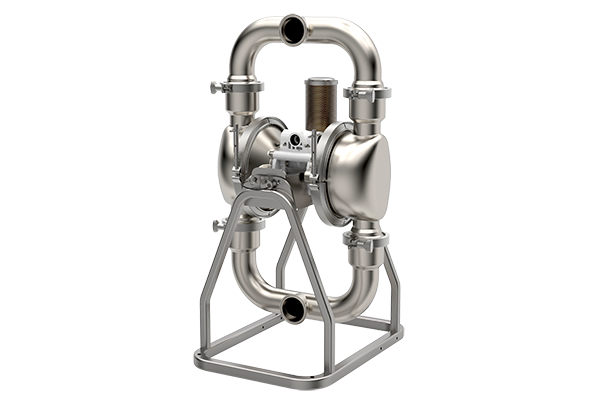

Our barrel unloading systems combine our unique One-Nut hygienic/sanitary style AODD pump with our barrel unloading skid - allowing you to pump highly viscous materials at increased flow rates.

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut Pump meets your application requirements.

Customize your sanitary drum pump with a selection of accessories, including discharge spouts, pump hangers, discharge hose, and Tri-Clamp® fittings.

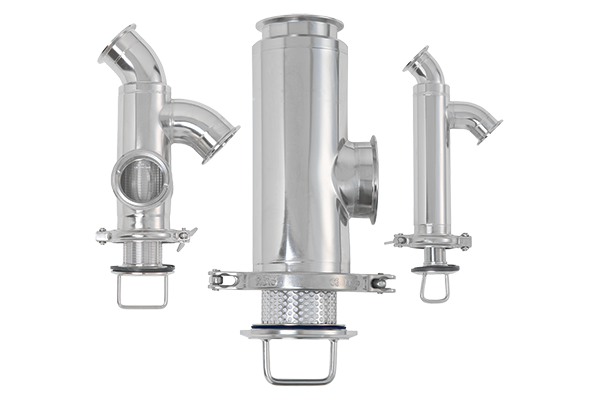

Engineered to remove pockets of air during the critical chromatography processes, our hygienic bubble traps feature an ultra-clean and installation-friendly design. We offer a wide array of sizes and port configurations.

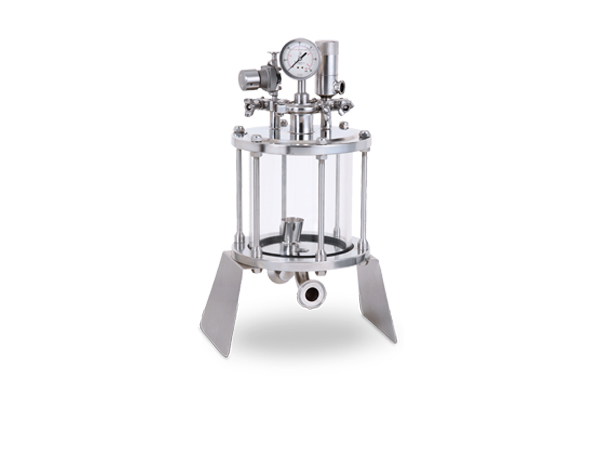

Sanitary sight glasses, available in various sizes, glass materials and pressure ranges, give you extra efficiency and protection while supervising your active process.

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of sanitary strainers in both standard and high capacity configurations.

View a complete selection of sanitary valves including pressure relief valves, check valves and butterfly valves.

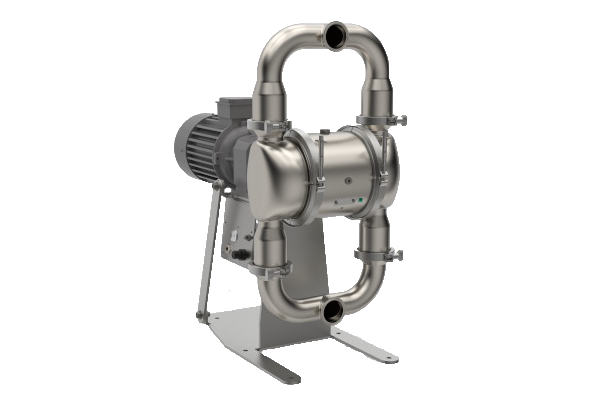

Electrically Operated Double Diaphragm Pumps

EODD pumps combine the advantages of an Air-Operated Double-Diaphragm Plus pump (AODD+) and the energy efficiency of an electric motor. EODD pumps can operate against a closed valve, run dry, and produce very little noise. Additionally, the pumps can operate in a low pulsation mode.

Air-Operated Double-Diaphragm Plus Pumps

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs. These pumps are fully drainable, machined from solid materials of stainless steel or Hastelloy® and are perfect for hygienic applications.