AODD Pump Transferring A Range Of Chemicals

UK based quilt and pillow makers based in relies upon several Air-Operated Double-Diaphragm Pumps from FPL in their production processes.

The company uses 20 million kgs of feathers and 10 million metres of cloth each year, in the production of well over half million quilts and nearly 5 million pillows!

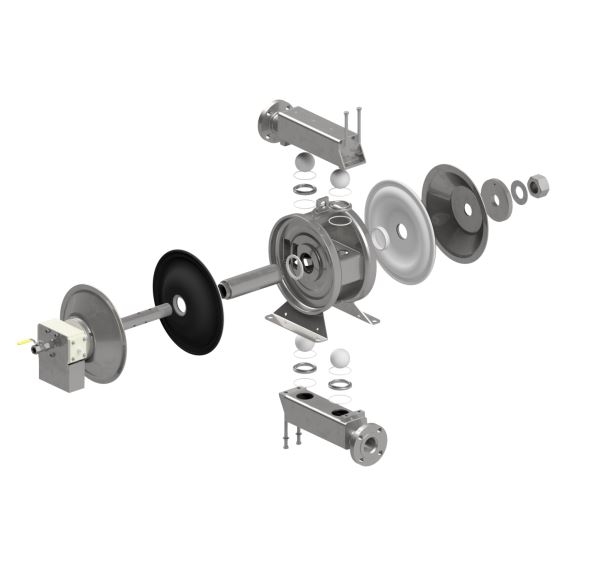

In the Cloth Preparation Department, Flotronic 710 Series AODD pumps are used to transfer a range of chemicals which include brightening agents, fire resistant agents and water proofing chemicals. A 710 Series 11/2 Stainless Steel pump, fitted with PTFE diaphragms delivers the chemicals to the cloth preparation rollers and another 710 Series pump handles the product recovery.

Two further stainless steel pumps are used in the Singeing Machine area handling Caustic and Peroxide. In the Colour Kitchen a further FPL pump is used, transferring water based paints with viscosity?s up to 35 Poise, to a header tank. For this application a Slimline Series 2" LoFlo Aluminium pump with PTFE diaphragms has been in operation since early 1996.

PROCESS DETAILS

- Products pumped include brightening & fire resistance agents, water proofing chemicals, caustic, peroxide and water based paints.

- Viscosity up to 35 Poise

- Temperature ambient

- Flowrates up to 240 ltr/min

PUMP DETAILS

- 710 Series 316 stainless steel

- Sizes 1" & 11/2" BSP

- PTFE diaphragms

- Barrier system

- Slimline Series Aluminium

- 2" Lo Flo BSP

- PTFE diaphragms