The Only AODD Able To Handle High Inlet Pressure

International Paint manufacturer with plants in Europe was having problems with standard AODD due to thermal expansion in pipelines outside the factory. Product was being heated up in the pipelines between bulk storage tanks and the production day tanks.

Standard Air-Operated Double-Diaphragm pumps can not withstand inlet pressures of more than approximately 0.7 bar on the inlet side of the pump. Pressures above this can cause premature diaphragm failure, along with product leakage through the air systems, which can destroy them. This is often a problem when the pumps are used with Clean-in-place rigs where cleaning liquids are pushed at pressure through the process pipe work and any in-line pumps.

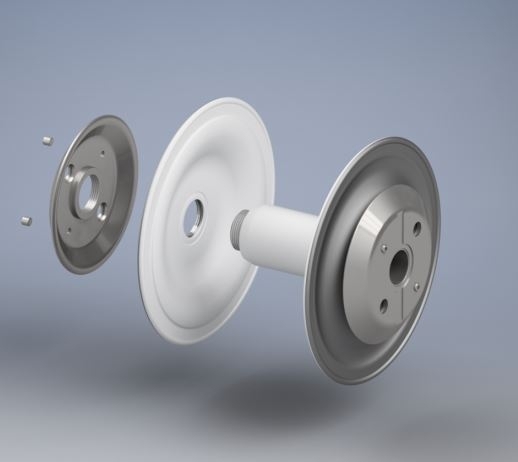

Flotronic Air-Operated Double-Diaphragm pumps can be upgraded with reinforced diaphragms which offer support to the back of the diaphragms when there are high inlet pressures as in the case of thermal expansion and Clean-in-place applications. This means that the Flotronic double diaphragm range can be upgraded to withstand up to 7bar suction inlet pressure.

BENEFITS

- Ability to withstand up to 7bar inlet pressure.

- Clean-in-place without needing to bypass the pump.

- Thermal expansion in the pipework can be dealt with.

- High inlet pressure from bulk tanks higher than 7m can be dealt with.