Food Fryer OEM Delivers Lower Total Cost of Ownership by Switching to Unibloc® Pumps

Background

A leading OEM of automated frying systems serving the food processing industry has built its reputation on delivering highly engineered frying and filtration equipment to processors worldwide. Its systems operate in some of the most demanding conditions in food manufacturing—transferring hot oil through continuous production cycles.

In these extreme environments, pump performance isn't just about flow rates. It's about hygiene, reliability under thermal stress, and maintenance simplicity. When equipment fails or requires extensive servicing, production stops, costs escalate, and food safety protocols are put at risk. For an OEM integrating dozens of components from multiple vendors into complex automated systems, the pump must be a solution—not a source of service calls.

Challenge

For years, this OEM relied on a common brand of positive displacement pumps across its equipment portfolio. While maintenance crews were familiar with these pumps, several persistent challenges emerged:

Hygienic concerns. The painted cast-iron construction and internal design raised sanitary questions from customers seeking cleaner, more modern solutions for food contact applications.

Maintenance complexity. Routine seal changes required extensive disassembly—decoupling motors, removing multiple components, and managing stacked mechanical seals with springs, polymers, and Teflon tape arranged in precise sequences. With five or six additional steps compared to modern alternatives, each service event increased the probability of reassembly errors.

High-temperature limitations. Operating in 400°F hot oil systems with viscous media and occasional crumb contamination demanded pumps engineered specifically for thermal expansion and extreme conditions.

Rising costs and service frequency. As competitor pump prices increased while construction quality remained unchanged, the total cost of ownership—including more frequent seal kit replacements and service interventions—became difficult for the OEM to justify.

In high-turnover environments where maintenance workers stay weeks rather than years, the complexity of the pumps compounded the risk of pump damage. Customers reported that training in general became a recurring challenge and that improper maintenance threatened both equipment performance and food safety.

Solution

More than 20 years ago, this OEM began integrating Unibloc® pumps from Unibloc Hygienic Technologies (UHT) into its filtration systems. The systems required positive displacement pumps because backflow restriction was critical. The results built trust quickly. As the OEM's lead mechanical designer noted, "When we put it on machines, we didn't usually hear about problems with it. That gave us a vote of confidence." In addition, the OEM began to see Unibloc pumps in competitors’ equipment, confirming they had made the right choice.

That confidence led to expanded applications. Today, Unibloc pumps are standard across the OEM's frying and filtration equipment lines, handling fresh oil supply, maintaining fryer levels, and managing filtration return flows.

Shifting gears: why Unibloc pumps became the standard.

Over time, the OEM standardized on Unibloc pumps for a number of reasons. Foremost was reliability. The OEM’s engineer said, "When you're dealing with hundreds of different components from dozens of vendors, you tend to go with the ones you get the fewest complaints about."

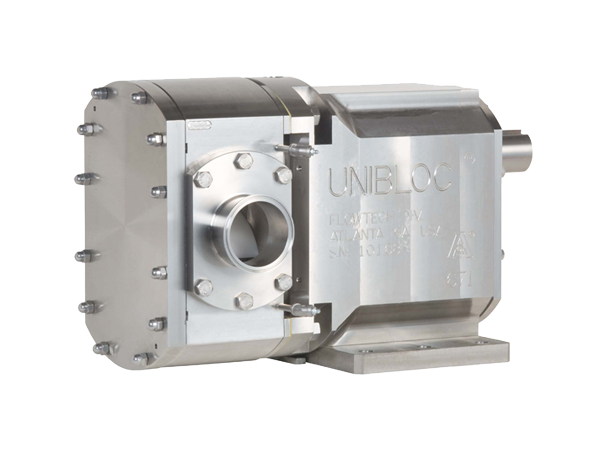

Also, the OEM valued the advanced, robust pump design. First was its all-stainless hygienic construction. Unlike painted cast-iron alternatives, the housing for Unibloc pumps was milled from a single billet of stainless-steel to avoid seams that could harbor bacteria. The design eliminated sanitary concerns and aligned with modern food safety expectations.

Also, the design was specially built with components that had proven high-temperature capability. Configured with high-temperature seals and optimized rotor clearances, Unibloc pumps reliably handled 400°F hot oil applications—conditions that caused other pumps to fail due to thermal expansion and internal binding.

The OEM’s customers loved the pump design for its time-saving accessibility. Customer maintenance crews didn’t need to disconnect piping, decouple motors, or work blindly through complex disassembly sequences. "The components are right in front of your face," explained the OEM's lead designer. "You literally take the cover off, and the impellers and seals just slide off from there."

The food processors also liked the intuitive, error-proof servicing. With fewer steps and one-way part assembly, the pump was simple to maintain. Even workers in the OEM’s own shop said that they appreciated that there's no guessing, no hidden components, and no risk of incorrect seal stacking or sequencing errors.

Results

After more than two decades of continuous use across hundreds of food processing equipment systems, the results speak clearly:

Fewer service interventions. Customers rarely contact the OEM about Unibloc pump issues, in contrast to legacy pump performance. Seal kit orders are significantly lower than with the older pumps.

Expanded performance range. Confident in the pump's reliability, the OEM has scaled applications from 30 GPM to 90+ GPM by adjusting drives and reducers, with no negative consequences even under increased demands.

Proven reliability and lower TCO. Compared to the pumps they replaced, Unibloc units generate far fewer service calls for the OEM. As costs for the older pumps escalated while their design stagnated, Unibloc pumps delivered better value—equal or greater capacity at comparable or lower cost, plus superior hygienic design and reduced maintenance costs for customers.

"We've been using Unibloc pumps for over 20 years—they just work."

"The Unibloc pump has a place in our industry. For the most part, our customers trust it."

"The old pump was costing just as much, if not more, for the same or less capacity. It became a really easy decision for us."

Recipe for Success

This case study demonstrates what "proven pump performance" means in practice: equipment that works reliably, in extreme conditions, with minimal intervention. For OEMs and processors alike, Unibloc® pumps deliver on three critical promises—Proven Total Cost of Ownership, Sanitary Performance by Design, and When Minutes Matter Maintenance Simplicity.

About Unibloc Hygienic Technologies

Unibloc Hygienic Technologies (UHT) delivers precision-engineered positive displacement and air-operated double-diaphragm pumps designed for the most demanding hygienic applications. Built for proven pump performance, UHT pumps are engineered to outperform, built to outlast, and designed to save more—giving processors and OEMs the durability, ease of maintenance, and Total Cost of Ownership savings they need to compete. Learn more at unibloctech.com.