The Right Pump Gives Fried Foods the Golden Touch

Batter up! According to Pristine Market Insights' Coatings Batters Market Report1, consumers with busy lifestyles want convenient meals, including batter-fried and batter-baked foods. The food industry is hoping to hit home runs by innovating with new batter textures, flavors, and gluten-free batters, all of which are expected to contribute to market growth. Also, in North America, growing interest in Asian cuisine ("What’s Hot" trend cited by the National Restaurant Association) is increasing the popularity of tempura-battered products.

To help food processors meet consumer demands, MP Equipment, Gainesville, GA, provides automated breading and batter coating equipment to the meat, poultry, seafood, and alternative protein processing industry. For more than 50 years, the company’s portioning and processing equipment has provided customers with solutions that are reliable, easy to clean and maintain, and lower the total cost of ownership.

Existing pumps were not giving the color and texture that consumers expected.

Food processors needed batter mixers and applicators that made their products look and taste delicious. The problem is that many processors who supply large retail chains and quick-service restaurant chains use in-line breading equipment that gives a poor color and texture to the finished product. The culprit? Inexpensive centrifugal pumps inside the equipment damage the integrity of the batter.

Managers at MP Equipment felt the best way to compete against larger, entrenched competitors was to solve the batter integrity issue along with other processor pain points. Tom Van Doorn, Director of Sales and Marketing at MP Equipment, said, "Our equipment needed to demonstrate areas of distinction that separated us from our competitors."

MP switched to a gentler pump that offered many benefits.

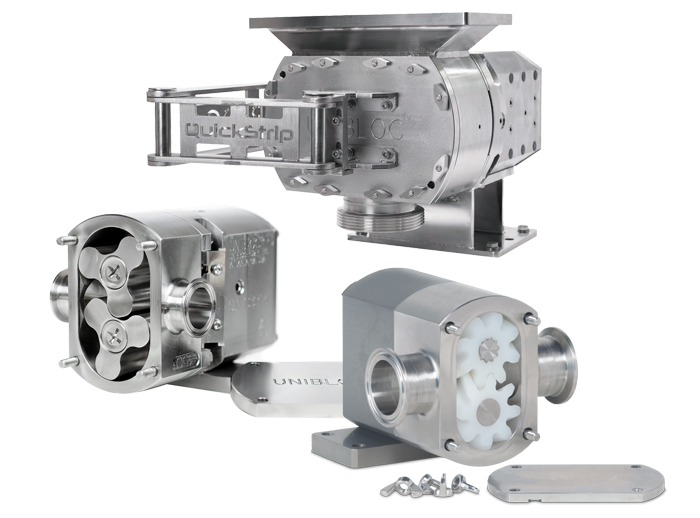

After a careful review of suppliers, the MP Equipment engineering team selected lobe pumps from Unibloc® Hygienic Technologies (UHT). UHT had a proven track record in the food industry for manufacturing hygienic pumps that provide gentle handling and high uptime.

Lobe pumps are a type of rotary positive displacement pump that traps a volume of product in a cavity and gently moves it to the pump outlet. In contrast, centrifugal pumps spin at high speed, causing shear that can damage the structure of the product being pumped. While centrifugal pumps are inexpensive and familiar to maintenance workers, they are not the best type of pump for batters, especially tempura, which has a high viscosity.

What's more, MP managers believed that its end customers could see the quality and food-safe design of the UHT pumps. "It’s machined out of a single billet of stainless-steel," said Van Doorn. There are no seams where food could collect and harbor bacteria. "It’s a uniquely high-quality pump," he said. Managers hoped this perception would help to distinguish MP Equipment’s systems in the marketplace and justify their higher price.

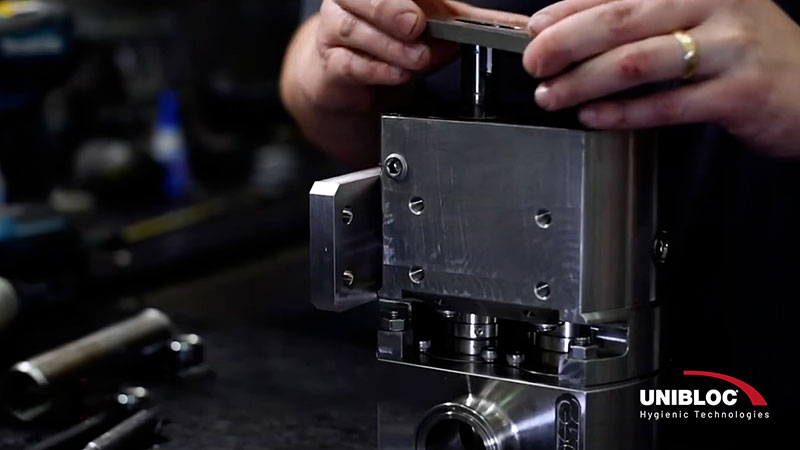

The engineers loved the way that the Unibloc® QuickStrip® FoodFirst pump lowers maintenance costs. The pump requires no tools for disassembly. The heavy pump cover is supported by a Safety Swing Arm, speeding cleaning. There are no rotor bolts that crews need to torque. In fact, cleaning crews can strip, clean, and return the pump to service in 20 minutes rather than two hours, as compared to a conventional pump. This ability would, the team hoped, make the MP Equipment system more attractive to customers.

Just as important, the engineers liked how the UHT pump was designed to reduce the chance of foreign objects entering the product stream. The Unibloc pump has no small parts in the pump head that maintenance crews could lose during cleaning. In addition, because the rotor is made of stainless-steel, this eliminated the chance of plastic wearing into the product.

There were other benefits to the design. Because pump seals are front-loaded, the pump can remain in place when a technician replaces the seals. Also, the pump eliminates mis-torqued rotor bolts as a cause of catastrophic pump damage.

All of these pump features aligned with MP Equipment’s focus on reliability, easy cleaning, food safety, and reduced maintenance. They installed the pumps in their 30-gallon and 70-gallon batter mixers and their batter applicators.

Based on customer feedback, the pump’s performance exceeded expectations, and the pumps have become a standard part of the equipment design.

"We have had some customers who have asked us to supply competitor pumps on their batter mixers, and we refuse to do it," Van Doorn said. "We can't guarantee our performance if we put a substitute in there."

Besides satisfying customers, the Unibloc pumps allowed the company to shift sales conversations away from price toward savings and return on investment. "These pumps are unique,” said Van Doorn. "They're extremely high quality. They offer gentle product handling, and leading hygienic design. They are easy and fast to clean thoroughly, and you can put them back together without tools."

How the right pump saved a multimillion dollar contract.

An operations manager for a major food processor called the customer team at MP Equipment, which is staffed 24 hours a day. His company battered and fried poultry and sold them as packaged foods to retailers. A very large retailer was complaining about the appearance of the products. A critical account was in jeopardy. Could MP Equipment help?

Quickly, MP Equipment arranged for a demonstration of its batter systems. Because the system's pump handled the batter gently, it gave a better result. "We put in a test machine and they bought it the next day," said Van Doorn. "They have continued to buy our applicators and batter mixers ever since."

"The fact that we use Unibloc pumps gives a better result," said Van Doorn. "The product, after it's through its process and cooked, has a very nice golden-brown appearance versus a kind of a gray appearance by the batter that's made with our competitors' equipment."

By switching to MP Equipment’s automated batter mixers and coaters, systems using the UHT pump, the company saved an account worth millions of dollars per year.

Working with Unibloc® Hygienic Technologies

MP Equipment offered a line-feeding solution for whole muscle and bone-in products. A custom system called the MP Meat Horn feeds a sheet meat line using two side-by-side conveyors. To increase reliability and reduce cost, a customer wanted to replace the system’s two pumps with a single large pump. Some of the engineers said it would not be possible.

The managers contacted UHT and explained what they wanted: a single pump system that would take product from a large dual cone hopper and push out the product in dual sheets.

The UHT engineering team helped MP Equipment to develop an improved MP Meat Horn having a single pump, effectively cutting customer pump maintenance needs in half and lowering the initial cost of the equipment.

About MP Equipment

MP Equipment, a Middleby brand, specializes in total processing line solutions—from consultation through integration. Its technology powers turnkey systems for high-capacity processing lines. Their products cover almost any process that a protein processor requires:

- Cutting.

- Forming.

- Slicing.

- Breading.

- Batter mixing.

- Batter application.

- Frying.

- Marination.

- Grinding.

- Freezing

About Middleby

Middleby is headquartered in the United States with over 10,000 employees worldwide in 100 countries. A publicly traded corporation, Middleby is a worldwide manufacturer of commercial kitchen equipment, residential appliances and systems for industrial food processing, packaging, and baking.

About Unibloc Hygienic Technologies

An industry leader in flow control technology and performance. Unibloc Hygienic Technologies offers precision-engineered positive displacement pumps, AODD pumps, drum pumps, and other highly engineered products for demanding flow control applications. UHT serves a variety of hygienic industries, including food, beverage, bakery/confection, meat and poultry, brewery, pharmaceutical, and transportation under the Unibloc®, Flotronic®, Standard Pump, and Hygenitec™ subsidiary brands. UHT’s highly efficient, easy-to-maintain products are designed to outperform and outlast competitive pumps in ways that drive Total Cost of Ownership lower.

Sources