Pumps for Beef and Pork Processors

Transferring ground meat poses unique challenges in terms of product safety, labor utilization, and pump maintenanceWe understand that the threat of recalls keeps beef and pork plant managers up at night. If bacteria are present, the grinding process can spread the contamination and move it deeper into the product where it is less likely to be eliminated during cooking. Also, foreign objects can be hidden in ground meat during processing, so they avoid detection during inspection.

Labor is another headache for managers. Good workers are scarce, especially for cleaning crews on the third shift. A lot of their efforts are devoted to manually cleaning pumps, a process that typically requires time-consuming disassembly and reassembly. Even the training may be taxing if turnover is high.

For meat processors, the cost of downtime is astronomical, while maintenance budgets are low. Anything that can increase reliability and reduce maintenance costs is welcome. Managers seek ways to reduce pump damage during cleaning, prevent worker injury, minimize the need for repairs, and speed up pump cleaning and maintenance times.

We know meat.

Our hygienic lobe pumps help beef and pork processors:

- Expedite cleaning and maintenance times by making pump disassembly fast and simple.

- Promote food safety with an exceptionally hygienic design.

- Avoid worker injury with tool-less disassembly and the Safety Swing Arm, a supported hinged cover.

- Reduce the risk of foreign-object contamination by having fewer small parts.

- Retain the physical integrity of the ground meat through gentle handling.

A pump design for the special needs of beef and pork processors.

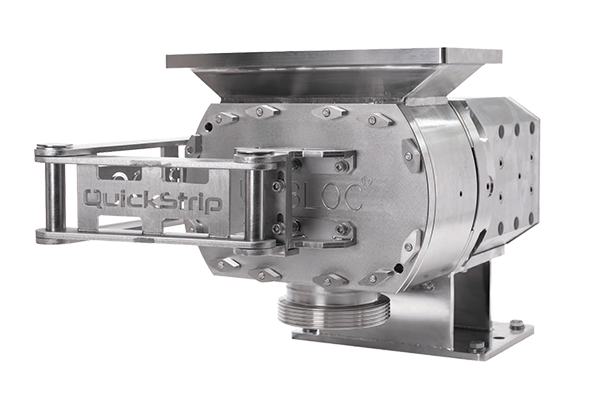

Drawing from our deep expertise in hygienic applications, we developed the Unibloc® QuickStrip® FoodFirst design to address the concerns of the meat processing industry.

The design starts by eliminating crevices that could harbor meat and bacteria. Unlike many pumps, Unibloc pumps feature a flat front cover with no spots for food to collect. The pump housing is created from a single piece of stainless-steel, so there are no seams. In contrast to pumps designed for metal-on-metal contact between the rotor and the cover, a Unibloc QuickStrip pump has no wear points that could introduce metal into the meat.

We designed the pump for fast, simple disassembly and reassembly. Compared to ordinary pumps, it has a concise design that limits excess and unnecessary parts that could enter the product stream by accident. Training is a snap because fewer steps are required, and parts are designed for one-way installation. Cleaning crews don’t even need tools for daily pump maintenance. Typically, a worker can clean the pump in 20 minutes rather than the hour that is usually required for other pump designs. This frees up workers for other tasks, efficiently utilizing workers’ time.

The Unibloc QuickStrip design helps to stretch maintenance budgets in other ways. Parts are unlikely to be damaged during cleaning. Because tools are not required for disassembly, it’s likely that the workers won’t gall the pump, leading to maintenance issues. Additionally, workers won’t risk injury with tools, avoiding a loss in productivity. Even the heavy front cover is supported by a unique safety swing arm, preventing a worker from dropping it on their foot and avoiding certain contamination by placing it on the floor.

Don't let unreliable pumps slow you down. Our lobe pumps have design features that support reliable operation every shift, every line, every day. Choose the lobe pumps built for the demands of beef and pork processing. With their robust design, superior durability, and unwavering reliability, you'll be investing in maximum productivity and long-term success.

Have questions or want more information about how our pumps can solve your operational challenges? Please reach out to us.

From the Blog

Meat Processing: Strategies for Reducing Maintenance Costs

How Some Meat Processors Are Addressing Labor Issues Using Technology

Minimizing Food Safety Risks in Meat Processing: The Role of Hygienic Pumps

Upcoming Events

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Explore Solutions

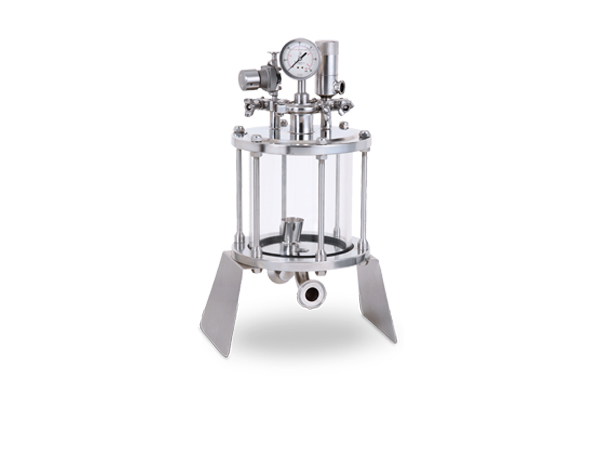

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

Providing a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBCs). Constructed from stainless steel and designed with Tri-Clamp® fittings, these pumps can be disassembled quickly for cleaning.

Designed for confined space applications in the food and beverage industries. Innovative, with easy mounting, pump motor alignment, smooth and quiet operation, and a small footprint.

Our barrel unloading systems combine our unique One-Nut hygienic/sanitary style AODD pump with our barrel unloading skid - allowing you to pump highly viscous materials at increased flow rates.

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut Pump meets your application requirements.

Customize your sanitary drum pump with a selection of accessories, including discharge spouts, pump hangers, discharge hose, and Tri-Clamp® fittings.

Engineered to remove pockets of air during the critical chromatography processes, our hygienic bubble traps feature an ultra-clean and installation-friendly design. We offer a wide array of sizes and port configurations.

Sanitary sight glasses, available in various sizes, glass materials and pressure ranges, give you extra efficiency and protection while supervising your active process.

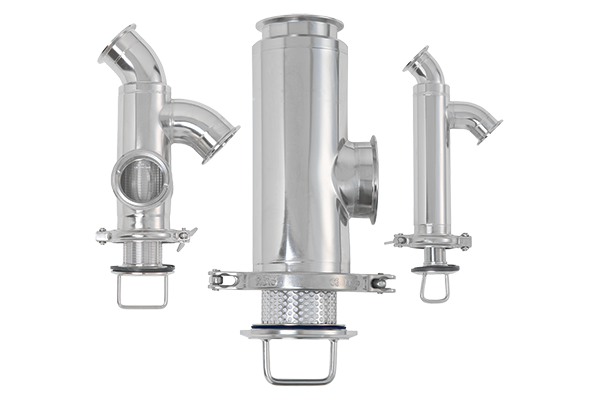

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of sanitary strainers in both standard and high capacity configurations.

View a complete selection of sanitary valves including pressure relief valves, check valves and butterfly valves.

Air-Operated Double-Diaphragm Plus Pumps

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs. These pumps are fully drainable, machined from solid materials of stainless steel or Hastelloy® and are perfect for hygienic applications.