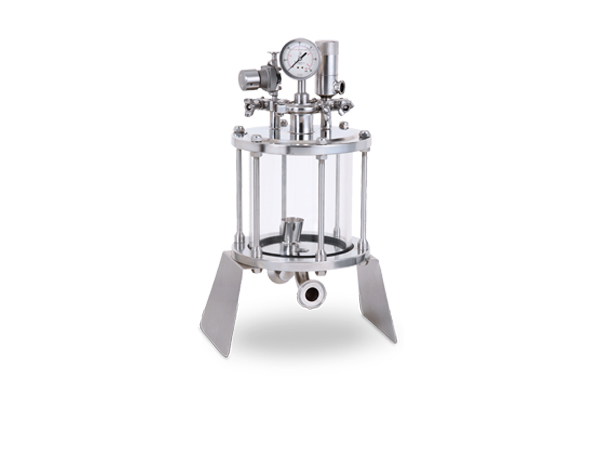

Bubble Traps

Engineered to remove pockets of air during the critical chromatography processes, our hygienic bubble traps feature an ultra-clean and installation-friendly design. We offer a wide array of sizes and port configurations.

Hygenitec™

Engineered to remove pockets of air during the critical chromatography processes, our hygienic bubble traps feature an ultra-clean and installation-friendly design. We offer a wide array of sizes and port configurations.

WHAT IS A BUBBLE TRAP?

A bubble trap is a device that removes air bubbles from aqueous solutions in-line or downstream in a fluidic system. Unfortunately, air bubbles in the fluidic flow can cause significant problems for applications because the bubbles unexpectedly change the intrinsic physical properties of the microfluidic environment. This change can increase the internal pressure abruptly in a fluidic/microfluidic system. It may lead to sudden shear force variations, which change the compliance of the system or even blocks small channels. Bubble traps are instrumental in ensuring a safe performance in any sanitary hydraulic system.

Unibloc’s bubble trap design comes with a number of benefits, including the electropolished 316L stainless steel material we use. We manufacture multiple sizes and port configurations for maximum customization, to give our customers the options they need for successful application. Our bubble traps come with comprehensive documentation, including material test reports and surface finish certification, so customers can count on our rigorous quality control.

From the Blog

View BlogWhy Flotronic® air-operated double-diaphragm pumps are so different we had to call them AODD+. Air-operated double-diaphragm pumps (AODD) pumps have been around since the 1950s. They are valued in a wide variety of applications because of their versatility. However, the proven, practical design of conventional AODD pumps has a significant drawback: they take too long to clean. Manually cleaning an AODD pump typically consumes two hours of labor or more.

Read BlogMeat Processing: Strategies for Reducing Maintenance Costs

The variety of available beef and pork products keeps increasing to meet consumers’ desire for convenience and choice. The more modern the processing facility is, the more plant managers and the industry can keep pace. Yet, automation is not as widespread as it seems, and, with budget constraints, companies must look for technologies that can improve their business operations in identifiable ways.

Read BlogHow Some Meat Processors Are Addressing Labor Issues Using Technology

Beef and pork processors have a lot on their plates. Not only must they keep down production costs, they have to do it while managing challenges posed by a scarce and low-skilled workforce. This blog post covers:

Read Blog