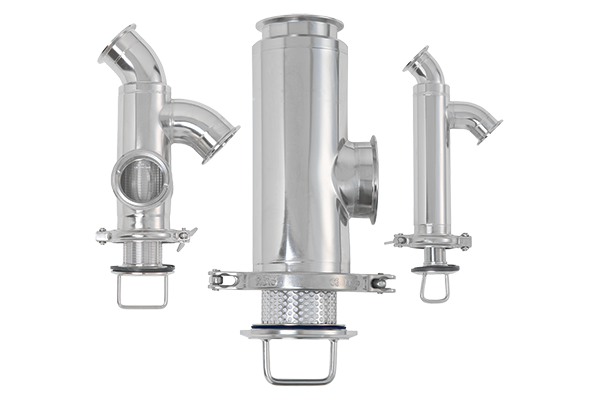

Pump Strainers

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of hygienic Y strainer and L strainers in both standard and high-capacity configurations.

Hygenitec™

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of sanitary strainers in both standard and high capacity configurations.

WHAT IS A SANITARY STRAINER?

A sanitary strainer is a piece of equipment that removes large particles from smaller particles required in the food & beverage and pharmaceutical industries. Furthermore, these strainers must maintain a 3A Certification to ensure the purity of the consumable products while allowing for ease of maintenance and cleaning.

Industrial sanitary strainers are essential to a safe and clean hygienic application, which is why we offer strainer customization. With Unibloc, you can choose between strainer size variations and mesh options in order to address processing needs. We even offer a choice between tempered glass or acrylic dual sight glass. The special requirements and application of sanitary strainers means you need a manufacturer you can trust to accommodate your needs.

From the Blog

View BlogTwin Screw vs. Lobe Pump? Which Pump is the Better Choice for Suspended Solids?

As food processors respond to rising consumer demand for protein-enriched products, from high-protein yogurts to enhanced dairy beverages, production lines face increasing challenges with thick, viscous formulations. With the food processing automation market approaching $40 billion by 2030, the industry seeks equipment capable of handling complex products without compromising throughput or quality.

Read BlogComparing Hygienic Pump Technology Pros and Cons: A Process Engineer’s Guide

In hygienic processing environments, pump selection plays a far greater role than simply moving product from point A to point B. The pump directly influences product integrity, ensuring easy cleaning, reducing food safety risks, minimizing maintenance efforts, and lowering total cost of ownership. For process engineers working in food, beverage, personal care, or pharmaceutical applications, understanding which hygienic pump technology is best designed for each application is essential to building reliable, repeatable processes.

Read BlogChallenging Pump Applications, Meet Your Match

The ultimate guide to knowing when to use twin screw pump technology —don’t let viscosity slow you down

Read Blog