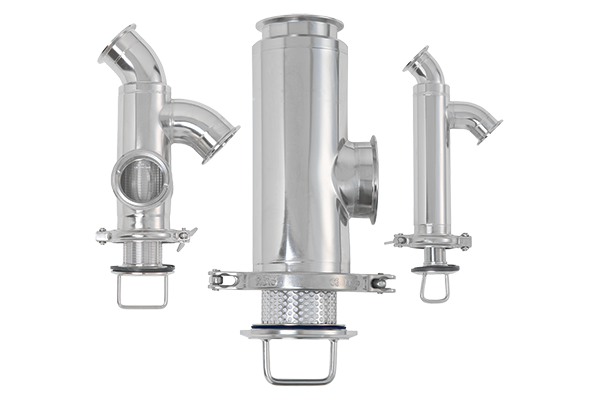

Pump Strainers

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of hygienic Y strainer and L strainers in both standard and high-capacity configurations.

Hygenitec™

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of sanitary strainers in both standard and high capacity configurations.

WHAT IS A SANITARY STRAINER?

A sanitary strainer is a piece of equipment that removes large particles from smaller particles required in the food & beverage and pharmaceutical industries. Furthermore, these strainers must maintain a 3A Certification to ensure the purity of the consumable products while allowing for ease of maintenance and cleaning.

Industrial sanitary strainers are essential to a safe and clean hygienic application, which is why we offer strainer customization. With Unibloc, you can choose between strainer size variations and mesh options in order to address processing needs. We even offer a choice between tempered glass or acrylic dual sight glass. The special requirements and application of sanitary strainers means you need a manufacturer you can trust to accommodate your needs.

From the Blog

View BlogWhy Flotronic® air-operated double-diaphragm pumps are so different we had to call them AODD+. Air-operated double-diaphragm pumps (AODD) pumps have been around since the 1950s. They are valued in a wide variety of applications because of their versatility. However, the proven, practical design of conventional AODD pumps has a significant drawback: they take too long to clean. Manually cleaning an AODD pump typically consumes two hours of labor or more.

Read BlogMeat Processing: Strategies for Reducing Maintenance Costs

The variety of available beef and pork products keeps increasing to meet consumers’ desire for convenience and choice. The more modern the processing facility is, the more plant managers and the industry can keep pace. Yet, automation is not as widespread as it seems, and, with budget constraints, companies must look for technologies that can improve their business operations in identifiable ways.

Read BlogHow Some Meat Processors Are Addressing Labor Issues Using Technology

Beef and pork processors have a lot on their plates. Not only must they keep down production costs, they have to do it while managing challenges posed by a scarce and low-skilled workforce. This blog post covers:

Read Blog