Positive Displacement Pumps for Dairy

Our precision-engineered positive displacement pumps suit the needs of any dairy application and help you fight downtime for optimal efficiency.Dairy processing involves a variety of materials and consistencies – from smooth, rich ice creams to all styles of cheeses, yogurts and more. In all types of dairy processing, you need positive displacement (PD) pumps that can handle a range of viscosities and pressures. Your dairy pumps should be easily reassembled after cleaning out of place (COP) to keep your production downtime minimum. No matter the product, successful processing requires a pump with low shear and consistent throughput.

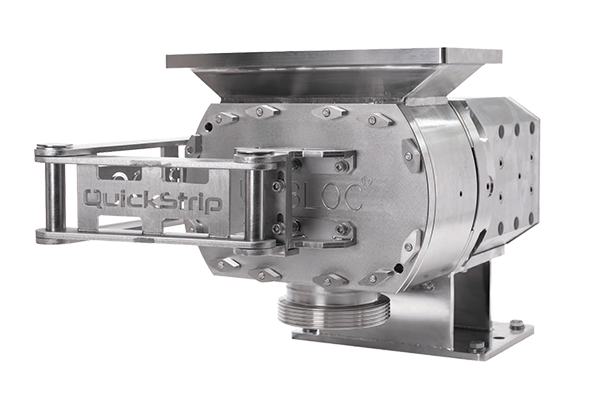

Your processing demands are unique, which is why our innovative PD lobe and gear pumps are precision-engineered in all stainless steel (which inspectors love) and feature a compact design that delivers smooth, low-shear performance while maintaining product integrity. Our PD pump solutions have been proven to simplify dairy processing without sacrificing the quality of any dairy product.

An example is yogurt applications in which they need to transfer flavors (such as strawberry or blueberry) out of drums. Often the drums have a hygienic liner that can be a challenge for a traditional pump (it will suck the product and bag into the pump). However, a UHT Standard pump product offers a special BagLiner series pump for this exact application.

Features and Benefits

Our sanitary pumps excel in the dairy industry and provide many benefits:

- Flat, crevice-free front cover that eliminates product dead zones

- CIP and COP capability

- Compact design

- Horizontal or vertical mounting versatility

- Elimination of pump and motor alignment issues

- Safe design with no accessible moving parts

- Easy maintenance

- Diaphragm rupture detection systems

From the Blog

What 3A Certification Means for Sanitary Pumps in the Dairy Industry

Comparing Gear Pumps to Lobe Pumps—Making the Proper Selection

Inside the Food and Beverage Industry: Air-Operated Double Diaphragm Pumps

Upcoming Events

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Explore Solutions

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

Providing a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBCs). Constructed from stainless steel and designed with Tri-Clamp® fittings, these pumps can be disassembled quickly for cleaning.

Designed for confined space applications in the food and beverage industries. Innovative, with easy mounting, pump motor alignment, smooth and quiet operation, and a small footprint.

Our barrel unloading systems combine our unique One-Nut hygienic/sanitary style AODD pump with our barrel unloading skid - allowing you to pump highly viscous materials at increased flow rates.

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut Pump meets your application requirements.

Customize your sanitary drum pump with a selection of accessories, including discharge spouts, pump hangers, discharge hose, and Tri-Clamp® fittings.

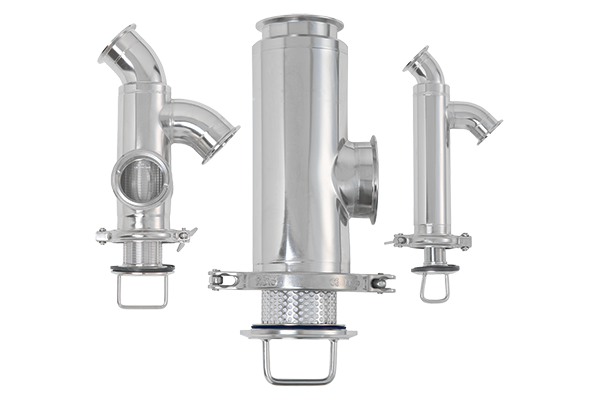

Engineered to remove pockets of air during the critical chromatography processes, our hygienic bubble traps feature an ultra-clean and installation-friendly design. We offer a wide array of sizes and port configurations.

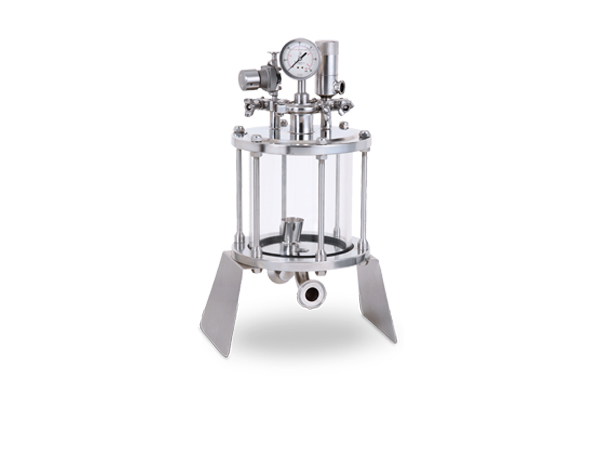

Sanitary sight glasses, available in various sizes, glass materials and pressure ranges, give you extra efficiency and protection while supervising your active process.

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of sanitary strainers in both standard and high capacity configurations.

View a complete selection of sanitary valves including pressure relief valves, check valves and butterfly valves.

Air-Operated Double-Diaphragm Plus Pumps

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs. These pumps are fully drainable, machined from solid materials of stainless steel or Hastelloy® and are perfect for hygienic applications.