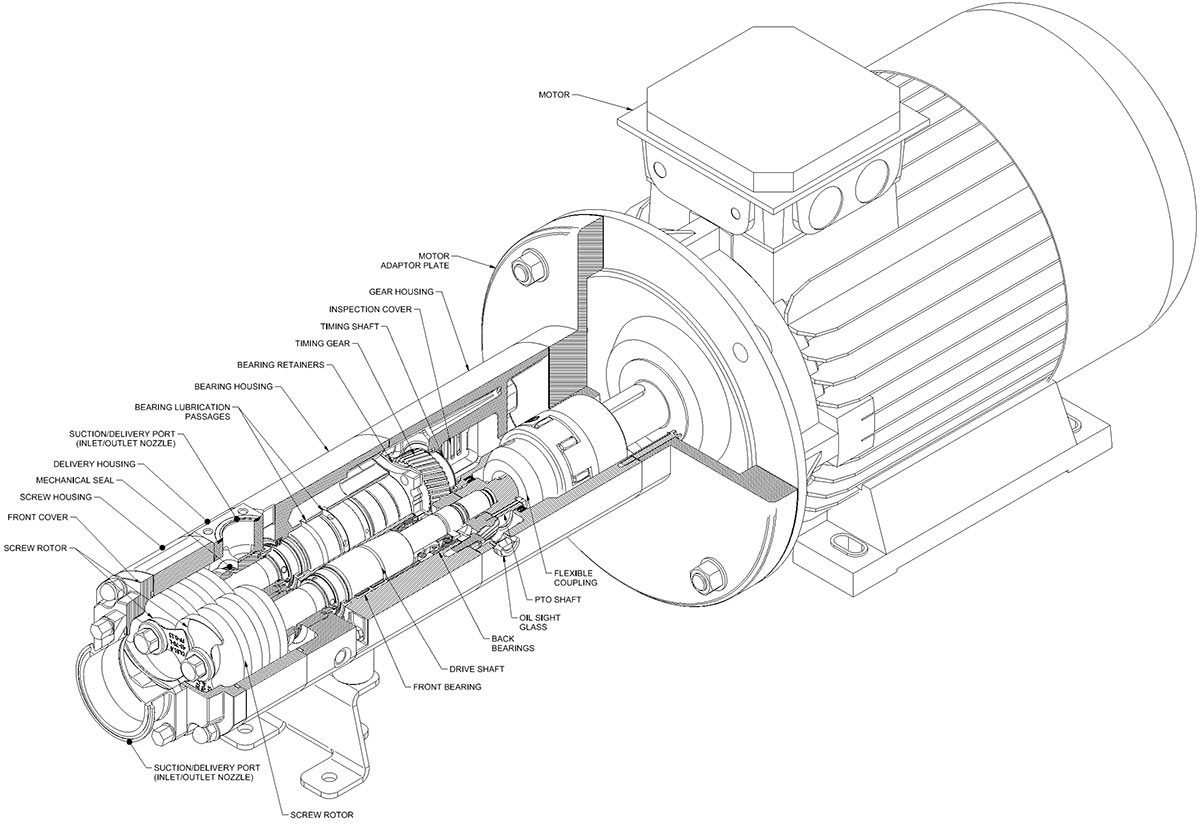

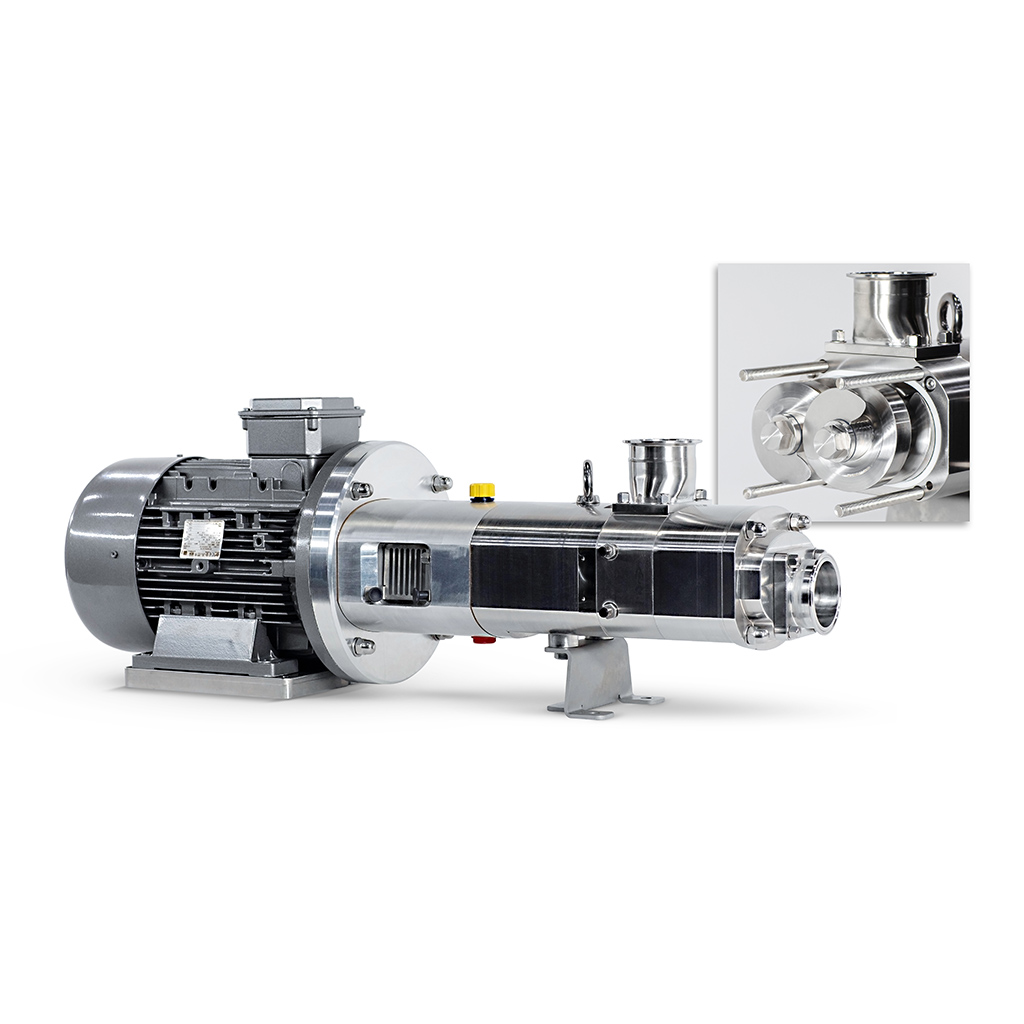

- Twin Screw Pump

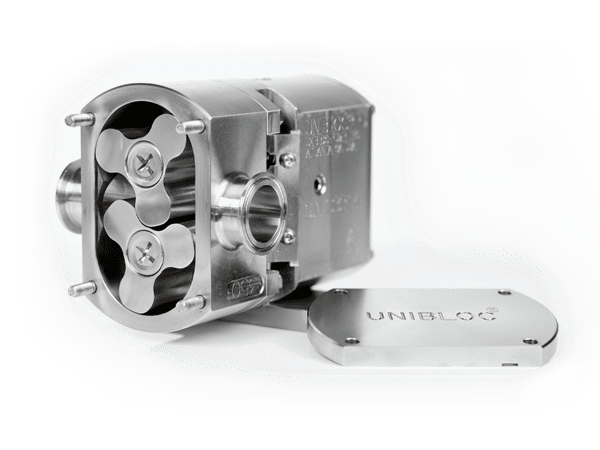

- Twin Screw Closeup

- Twin Screw Closeup

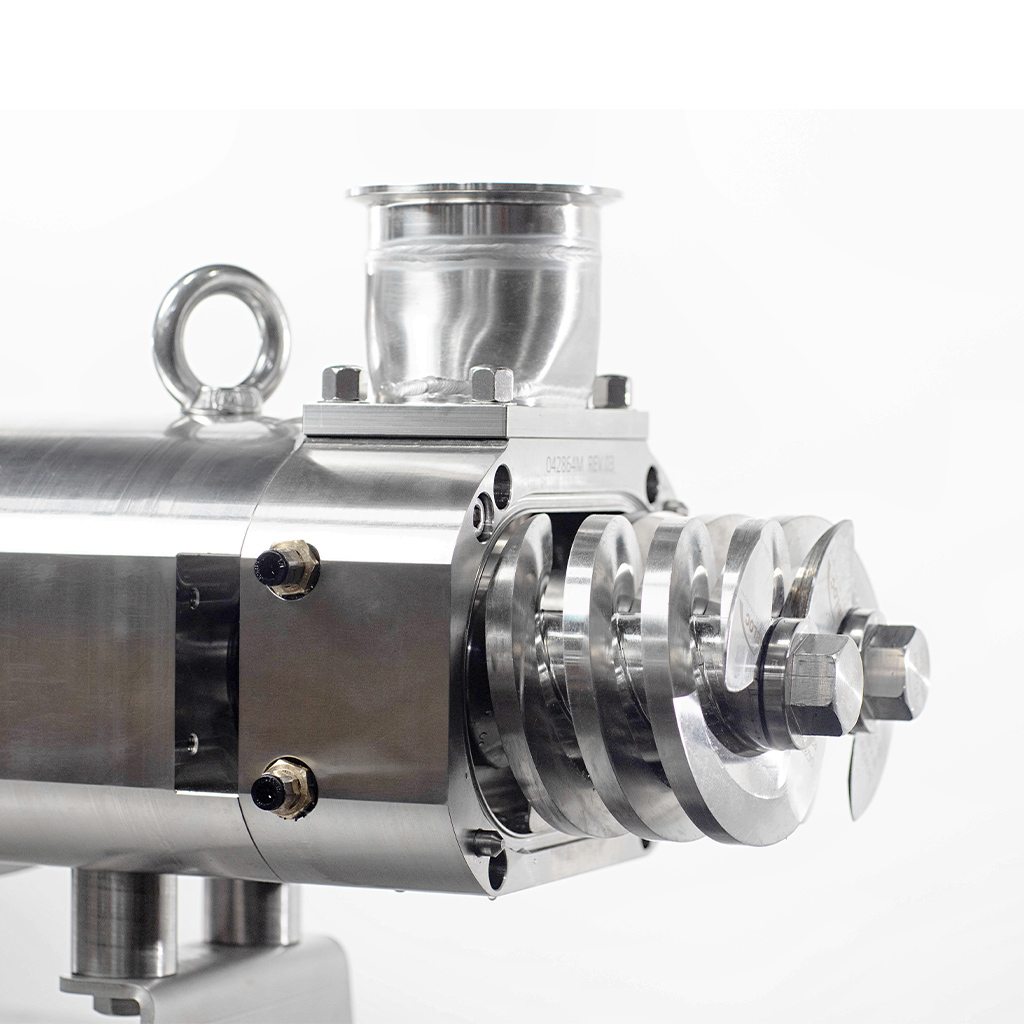

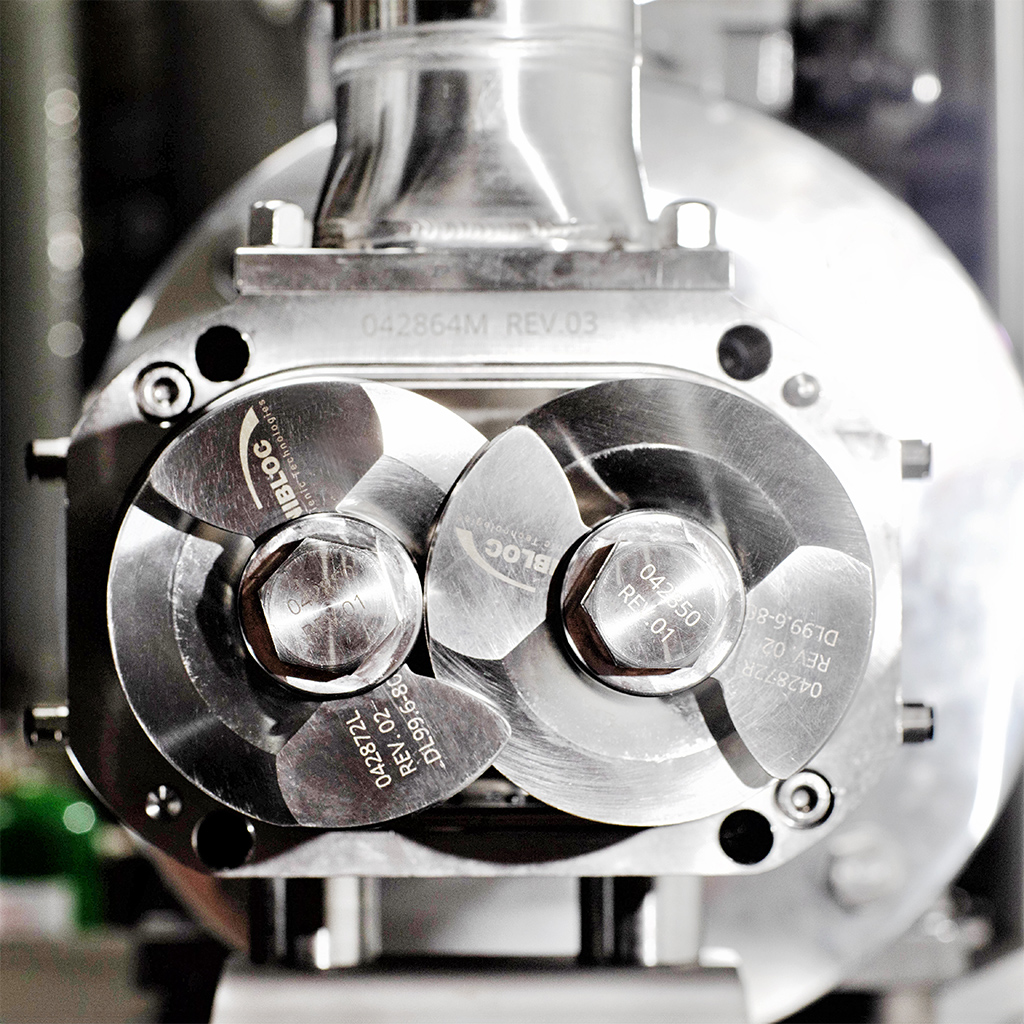

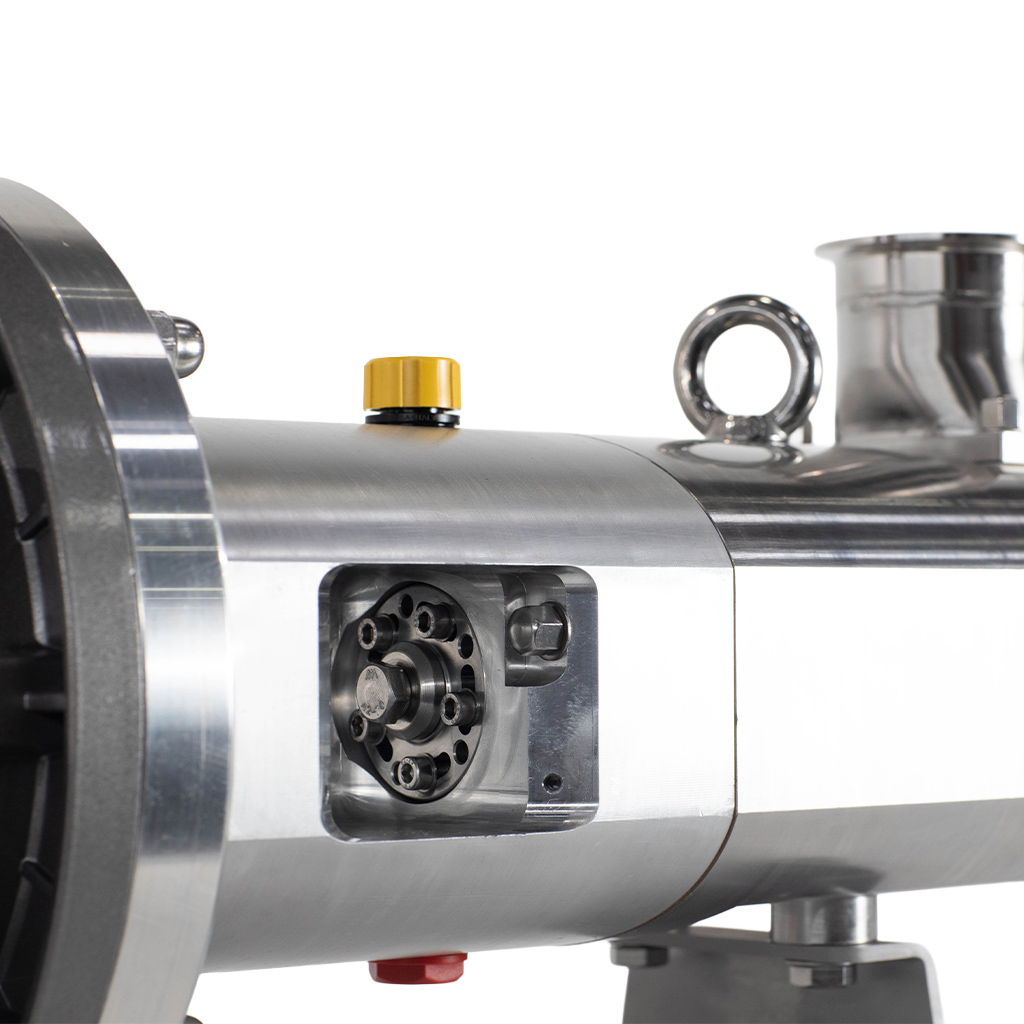

- External Timing Access

- External Timing Access

- Twin Screw Pump

Twin Screw Pump

Twin Screw Closeup

Twin Screw Closeup

External Timing Access

External Timing Access

Twin Screw Pump

Unibloc® Twin Screw Hygienic Pumps

Finally, a Twin Screw Hygienic pump that delivers what ordinary twin screw pumps can’t: Less downtime. Less complexity. More performance.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

Key Features

- External timing adjustment without opening internal oil-filled housings.

- Foolproof one-way screw reassembly.

- Bi-directional flow reverse pumping feature enables complete emptying capability, minimizing product waste and ensuring thorough cleaning between batches.

- Unlike other screw pumps on the market, this pump uses identical drive and lay screw shafts, simplifying both assembly and spares inventories.

- Meets 3A sanitary standards and supports clean-in-place (CIP) processes.

- Handles everything from small-batch specialty products to high-volume production runs.

Game-Changing External Timing Adjustment

Unibloc® Twin Screw positive displacement (PD) pumps redefine what’s possible in high-pressure hygienic applications. While other pumps require disassembly for timing adjustments, our externally adjustable timing system enables precision adjustments in just five minutes. No disassembly, no contamination risk from opening oil-filled housings on the production line, minimized downtime.

Foolproof One-Way Screw Reassembly

The new Unibloc Twin Screw pump features an innovative design that ensures perfect alignment every time, eliminating guesswork during assembly. With identical drive and lay screw shafts, reassembly is simpler and spare parts inventory is streamlined, reducing complexity across maintenance operations. This design allows technicians to get reassembly right on the first try—without rework.

Ultra-Hygienic Design

Fewer parts than competing screw pumps reduce the risk of foreign object contamination, while our advanced oil reservoir design delivers optimal flow and circulation for superior heat dissipation and extended bearing life.

High-Performance Applications

- Delivers the highest discharge pressure of any hygienic pump.

- Handles viscous products up to 1,000,000 cP.

- Ideal for shear-sensitive products with entrained solids up to 45mm.

- Minimize waste with effective Clean-In-Place (CIP) via reversible operation.

- The family of four pumps has flow capacities from 200 to 1200 gallons (757 to 4542 liters) per minute with volumetric efficiency greater than 90%.

- The pumps can operate at temperatures up to 248° F (120 °C) and at system pressures of 360 psi (24.8 bar) to enable their use with a wide range of products.

- Operating speeds up to 3600 RPM for increased productivity.

Benefits

- Advanced design and fewer parts lead to easier, simpler, faster maintenance.

- External access to timing adjustments – without having to open messy oil-filled housings.

- Preserves the integrity of shear-sensitive, high-viscosity products, handling everything from small-batch specialty products to high-volume production runs.

- Smooth, consistent non-pulsating flow even at high flow rates.

- Dual-duty design — a single pump for processing at low speeds or effective CIP at higher speeds.

| Screw Diameter | Ports | PSI (Bar) | RPM | Flow per Minute |

|---|---|---|---|---|

| 3-inch (080 mm) |

3-inch | 360 psi (24.8 bar) |

3600 | 200 gallons/min (757 liters) |

| 4-inch (100 mm) |

3-inch | 360 psi (24.8 bar) |

3000 | 300 gallons/min (1135 l/min) |

| 5-inch (130 mm) * |

5-inch | 360 psi (24.8 bar) |

1800 | 380 gallons/min (1438 l/min) |

| 7.5-inch (190 mm) * |

8-inch | 360 psi (24.8 bar) |

1800 | 1200 gallons/min (4542 l/min) |

*Availability pending.

Brochures

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Complementary Products

A compact and self-draining Diaphragm Pump available in FDA approved 316L stainless steel, aluminium, Duplex 22, and Hastelloy®; used in an array of industries.

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications.

A fully machined gearbox at its core, this lobe pump sets the highest industry standards for performance, providing sanitary solutions for a variety of applications.