When it comes to food processing, performance and reliability matter most. In this customer success story, MP Equipment, a trusted designer of industrial food processing systems, shares how partnering with Unibloc Technologies helped them streamline production with pumps that deliver sanitation, durability, and unmatched efficiency.

Watch VideoEveryday processors depend on hygienic pumps to keep operations running smoothly — but not all pumps are created equal. In this video, discover why Unibloc’s Unit Block pumps have become the go-to choice for operators who demand durability, efficiency, and lower operational costs. From mission-critical reliability to smarter sanitation and maintenance, Unibloc pumps are engineered to withstand the toughest processing environments. Hear how operators are reducing downtime, improving performance, and keeping production moving with confidence.

Watch VideoThe Unibloc UHT Twin Screw Pump is designed for high-performance hygienic processing across food, dairy, beverage, pharmaceutical, and biotech applications. Featuring true twin-screw technology, gentle product handling, and exceptional cleanability, the UHT delivers precision flow control without compromise. Engineered for reliability, flexibility, and sanitary excellence, Unibloc pumps help manufacturers protect product integrity while maximizing efficiency and uptime.

Watch VideoSee how a Flotronic® AODD+ pump, with its unique One-Nut® design, greatly accelerates cleaning and maintenance times compared to a traditional AODD pump. Watch this video of a head-to-head comparison of a Flotronic AODD+ pump vs. a traditional double-diaphragm pump and see the difference for yourself. Watch as a worker disassembles a Flotronic AODD+ pump in just three steps while disassembling a traditional air-operated double-diaphragm pump requires 18 steps. There is plenty of time for the first worker to move on to other maintenance or cleaning tasks. Also, there is only one large nut to keep track of, compared to more than 50 parts to keep track of with a traditional pump. That represents 50 fewer opportunities for a small part to be lost into the process fluid. What’s more, a Flotronic AODD+ pump stays in-line for cleaning, while a traditional double-diaphragm pump requires disconnection from the line. Not all hygienic diaphragm pumps are created equal. That’s why we say: You may have tried an AODD, but that’s nothing like a Flotronic AODD+!

Watch VideoMachined from solid material, Flotronic's fully drainable Slimline pumps can be used in a wide range of industries for any liquid transfer. The food and beverage industry commonly employs air-operated double-diaphragm (AODD) pumps because of their flexibility. To ensure food safety, the pumps must be cleaned frequently. Clean-in-Place (CIP) processes are preferred when the application allows, as Clean-out-of-Place (COP) requires a worker to strip down the pump and clean it manually. Although AODD pumps can be cleaned using integrated CIP equipment, most AODD pumps are not compatible with external CIP rigs. Alone among AODD-style pumps, the Flotronic Slimline series can accommodate external rigs for CIP processes. The secret is its inside-out design that eliminates extra pipework. The Flotronic ® One-Nut® pump, fitted with reinforced diaphragms, can be cleaned-in-place at up to 7 Bar without damaging the pump. The pump can be used with external CIP rigs or the pump itself can be used to transfer the CIP materials. Once CIP has been completed, the pump drains completely without manual intervention (when configured with optional slotted seats). Flotronic's Slimline pumps may be more compact than competitor air-operated double-diaphragm Pump (AODD) pumps, but they’re just as capable - offering all the benefits for which Flotronic pumps are renowned, including Flotronic’s innovative, easy-maintenance, One-Nut design, which allows pump maintenance in a matter of minutes.

Watch Video

Welcome to Unibloc® Hygienic Technologies, where excellence meets innovation in poultry pump performance! Poultry processors demand top-notch equipment to drive their production lines efficiently, and our brands are designed precisely for these unique demands.

Our Unibloc Hygienic Technologies family of products delivers cutting-edge solutions that redefine the poultry processing landscape. The QuickStrip® FoodFirst PD pump design, a hallmark of our innovation, guarantees top-tier poultry processing performance, ensuring optimal efficiency and safety every time.

At Unibloc Hygienic Technologies, we bring proven expertise drawn from the most demanding poultry facilities globally. Elevate your poultry pump performance with our innovative solutions.

Peco Foods has thrived for more than 80 years, committed to quality and safety. It faced a challenge at its chicken nugget processing plant in Arkansas due to the complexity of efficiently moving ground chicken at temperatures below freezing. The plant processes 9,000 pounds per hour, so any issues or roadblocks that affect its processing systems, maintenance schedules, and food safety are costly. Find out how our Unibloc® QuickStrip® PD600 series lobe pump addressed every issue in this video.

Watch VideoUnibloc Hygienic Technologies, Inc. (UHT), a global leader in hygienic positive displacement pumps, AODD pumps, drum pumps, and other flow control products, has expanded production capacity at its Bolney, UK facility with a significant investment in additional machining technology. The investment continues UHT’s ongoing strategy of increasing production capacity to reduce production lead times and improve customer service.

Watch VideoWith our recent acquisitions of industry leaders Flotronic and Standard Pump, Unibloc has now become Unibloc Hygienic Technologies (UHT). Building on a tradition of innovation from three separate organizations, these products and teams of experts have come together to provide our customers with the technology and support they need every day.

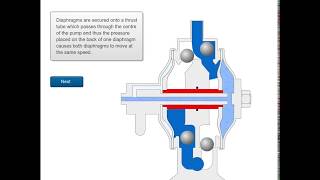

Watch VideoHow an Air-Operated Double-Diaphragm pump works. Showing the Unique Flotronic Pumps Inside Out design of Air-Operated Double-Diaphragm pump, which allows strip and build in less than 15 minutes. The only AODD that can withstand more than 1bar inlet pressure.

Watch Video15 Minute video showing a FULL service on the unique Flotronic Air-Operated Double-Diaphragm pump. Easier strip and rebuild than any traditional AODP.

Watch VideoFlotronic - Air-Operated Double-Diaphragm pump/barrel unloading system on concentrated tomato paste.

Triple concentrate tomato paste in 240 Kg drums - no problem for the Flotronic AODP - emptying the drum in 2.5 minutes - less than 1% product left in drum. Sanitary style pump with inflatable seal used on follower plate ensures easy cleaning.

Watch VideoVideo of emptying concentrated tomato puree from 240 Kg taper drum. Sanitary Air-Operated Double-Diaphragm pump mounted in our barrel unloading system with inflatable seal, ensures easy Strip-down and clean, and can be cleaned in place if required.

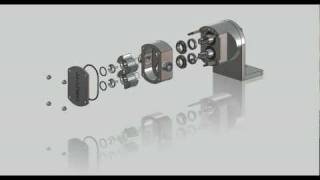

Watch VideoAnimation of the Polypropylene version of our 'One Nut' Air-Operated Double-Diaphragm pump showing ease of Strip-down and the very limited number of components when compared to any traditional AODP.

Watch VideoChange diaphragm in less than 5 minutes while the pump remains in-line with the process pipework.

Watch VideoChanging a diaphragm on a pump fitted with our Guardian Diaphragm Rupture Protection system - The Guardian system protects the local environment, personnel and the pump air system in the event of any diaphragm failure.

Watch VideoExample shown is a Standard PTFE divider seal being fitted to a Stainless Slimline pump with 10" Diaphragms - same method on most of the Flotronic diaphragm pump range, including the 500 series Plastic and the Minichem / Chemflo PTFE pump ranges.

Watch VideoFitting fully bonded PTFE diaphragms to a Flotronic pump - Note: method is the same across the range of our standard pumps.

Watch VideoFlotronic's unique Air-Operated Double-Diaphragm design allows air valve replacement without needing to strip the pump; meaning it can be done while the pump remains 'in-line'.

Watch VideoRemoving Standard Divider Seal - Note Divider Seal Groove is machined deeper at the top to make removal easy.

Watch VideoUK based food manufacturer needed to speed up the pumping of molasses (15,000 Cps) from plastic IBC, to 18 litre container prior to weighing. Trial to prove the Flotronic Air-Operated Double-Diaphragm pump. Pumped at 1Kg per second. Then cleaned in place without stripping pump down.

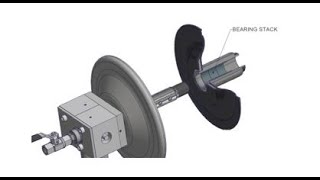

Watch VideoTie Rod & Thrust Tube assembly - Tie Rod always enters the Thrust tube at the end where the internal bearings are closest.

Watch VideoAnimation of the Unique 'One Nut' Air-Operated Double-Diaphragm

Watch VideoPumping warm chocolate containing whole almonds - The Flotronic Good Food Pump is the perfect Air-Operated Diaphragm Pump for this application.

Watch VideoIn This example the PTFE Snap Fit Divider seal is being inserted into A Sanitary Style 316L pump with 12" Diaphragms - insertion technique is the same for all Snap Fit Divider Seals - Special Tool supplied with pumps.

Watch VideoRemoving a Snap Fit Divider Seal from a 12" Stainless Slimline Pump - Technician is seen pushing out the seal with his finger - You may need to use any blunt ended instrument (Preferably Plastic) to achieve the same.

Watch VideoAnimation showing the Strip-down of a Sanitary Style 316L Stainless Steel Air-Operated Diaphragm Pump from Flotronic Pumps.

Watch VideoFlotronic Drum / Barrel Unloading system pumping Silicone Elastomer (500,000Cps) from Barrel to Mixing vessel, 210 litres in 4 minutes.

Watch VideoUltraMass Flow Meter Water Test Demonstration

Watch VideoTechnical illustration on how to assemble and disassemble a Standard Pump SP-800 series pump.

Watch VideoStandard Pump Inc. manufactures fluid handling equipment for the chemical, water treatment, automotive, food and cosmetic industries. Headquartered in Duluth, Ga. Standard Pump has a distribution network that expands into over fifty countries. Learn more about our vision, capabilities and culture.

Watch VideoCheck out our “how to operate” videos and start stripping downtime, cost and number of tools needed to reassemble.

Watch VideoUnibloc-Pump is proud to present the revolutionary Compac™ Series of coupled pump solutions. This innovative design delivers a user friendly, simplified pump system. From the unique and straightforward design of the Compac Direct, to the unmatched versatility of the Compac Flex, the Compac Series offers a complete line of sanitary lobe and gear pumps for a wide range of industries and applications. Check out our “how to operate” videos and start stripping downtime, cost and number of tools needed to reassemble.

Watch VideoUnibloc Pump is the innovation leader in premium sanitary positive displacement pumps for pharmaceutical, meat & poultry, tanker truck fleets, food & beverage, dairy, brewery and more industries. Fight downtime with a Unibloc Pump. Lobe and Gear pumps, plus innovative strainers, valves, sight glasses and more. Check out our “how to operate” videos and start stripping downtime, cost and number of tools needed to reassemble.

Watch VideoPrecision engineered from stainless steel, our PD 600 series of pumps house free-floating rotors containing no rotor bolts. Unibloc's innovative pump design is suited for food processing applications requiring daily strip-down sanitation. Check out our “how to operate” videos and start stripping downtime, cost and number of tools needed to reassemble.

Watch VideoUsed for filtration by the most respected beverage manufacturers in the world, Unibloc has the largest selection of strainers. From large diameter to small, and from high volume transfer to very viscous product needs, we have strainers in both Y and L configurations. We offer sizes from three-quarter to six inches. Check out our “how to operate” videos and start stripping downtime, cost and number of tools needed to reassemble.

Watch VideoDiscover QuickStrip technology from Unibloc Pumps, the perfect solution for daily sanitary/food processing applications. Easy to assemble, easy to use. Check out our “how to operate” video and start stripping downtime, cost and number of tools needed to reassemble. Learn more www.uniblocpump.com. Our patented QuickStrip technology is designed to better handle the challenges of daily sanitation. Much of the damage sustained by on pump components occurs during the sanitation process, resulting in expensive repair and re-machining. Our QuickStrip rotors and wear pads withstand wear and tear by providing plastic on metal contact, not metal on metal. They also offer tool-free disassembly, resulting in decreased downtime, an easier to maintain pump and lower cost of ownership.

Watch VideoDiscover QuickStrip technology from Unibloc Pumps for use in sanitary/food processing facilities. With its patented COP Clean-out-of-place design, Unibloc QuickStrip pumps cut downtime, reduce cost and minimize the number of tools needed during pump breakdown or reassembly. Learn more www.uniblocpump.com Our patented QuickStrip technology is designed to better handle the challenges of daily sanitation. Much of the damage sustained by on pump components occurs during the sanitation process, resulting in expensive repair and re-machining. Our QuickStrip rotors and wear pads withstand wear and tear by providing plastic on metal contact, not metal on metal. They also offer tool-free disassembly, resulting in decreased downtime, an easier to maintain pump and lower cost of ownership.

Watch VideoUnibloc Pump Truck Pumps are known for being the most reliable, easy to maintain, food-grade pumps on the road today. Engineered to handle the rigorous demands of daily loading and unloading. They are lightweight, compact and offer versatile mounting options. Our innovative O-lip shaft seals are the longest lasting, most dependable seals in production thus eliminating common and costly seal leak issues.

Watch VideoUnibloc Pump Truck Pumps are known for being the most reliable, easy to maintain, food-grade pumps on the road today. This step-by-step video demonstrates how to replace double O-lip seals for the Unibloc Pump PD551 sanitary positive displacement pump for truck pumps in the tanker transportation industry. Our transportation solutions are engineered to handle the specific demands of loading and unloading tankers, while utilizing minimal space on the vehicle. Our light-weight Road Tanker pump features a compact design, with front loaded shaft seals and rotors designed specifically for low repair cost, easy cleaning and maintenance. They’re constructed from stainless steel with the cleanest pump head in the industry, and the compact bearing housing has proven to withstand the everyday rigors of the transportation industry. Parts • Seals: 5272 • Tools: 6230 and 6130 • Sleeves: 4939B-CRO • Shim Kit: PD501-Front Shim

Watch VideoUnibloc Pump Truck Pumps are known for being the most reliable, easy to maintain, food-grade pumps on the road today. This step-by-step video demonstrates shimming a Unibloc Pump PD551 sanitary positive displacement pump for truck pumps in the tanker transportation industry. Our transportation solutions are engineered to handle the specific demands of loading and unloading tankers, while utilizing minimal space on the vehicle. Our light-weight Road Tanker pump features a compact design, with front loaded shaft seals and rotors designed specifically for low repair cost, easy cleaning and maintenance. They’re constructed from stainless steel with the cleanest pump head in the industry, and the compact bearing housing has proven to withstand the everyday rigors of the transportation industry. Parts: Seals: 5272 Tools: 6230 and 6130 Sleeves: 4939B-CRO Shim Kit: PD501-Front Shim

Watch VideoUnibloc Pump Truck Pumps are known for being the most reliable, easy to maintain, food-grade pumps on the road today. This step-by-step video demonstrates relief valve servicing for the Unibloc Pump PD551 sanitary positive displacement pump for truck pumps in the tanker transportation industry. Our transportation solutions are engineered to handle the specific demands of loading and unloading tankers, while utilizing minimal space on the vehicle. Our light-weight Road Tanker pump features a compact design, with front loaded shaft seals and rotors designed specifically for low repair cost, easy cleaning and maintenance. They’re constructed from stainless steel with the cleanest pump head in the industry, and the compact bearing housing has proven to withstand the everyday rigors of the transportation industry. Parts: Seals: 5272 Tools: 6230 and 6130 Sleeves: 4939B-CRO Shim Kit: PD501-Front Shim

Watch VideoUnibloc Pump Truck Pumps are known for being the most reliable, easy to maintain, food-grade pumps on the road today. This step-by-step video demonstrates how to replace double O-lip seals for the Unibloc Pump PD551 sanitary positive displacement pump for truck pumps in the tanker transportation industry. Our transportation solutions are engineered to handle the specific demands of loading and unloading tankers, while utilizing minimal space on the vehicle. Our light-weight Road Tanker pump features a compact design, with front loaded shaft seals and rotors designed specifically for low repair cost, easy cleaning and maintenance. They’re constructed from stainless steel with the cleanest pump head in the industry, and the compact bearing housing has proven to withstand the everyday rigors of the transportation industry. Parts: Seals: 5272 Tools: 6230 and 6130 Sleeves: 4939B-CRO

Watch VideoA single mechanical seal consists of two flat seal faces, amalgamated together by a spring while sliding against one another. A film is produced between the two seal faces from the process fluid/lubricant cooling the seal’s internals, creating a protective barrier. An absence of the film results in frictional heat and ultimately, the breakdown of the mechanical seal. To keep your single mechanical seal operating properly, ensure that: • the seal is receiving the proper quality and quantity of lubricating oil • there is no debris being introduced to the sealing faces • the sealing faces and/or O-rings aren’t damaged during installation This step-by-step video demonstrates how to replace single mechanical seals for the Unibloc Pump PD300 – 575 series of sanitary positive displacement pumps. A single mechanical seal is typically used when the process fluid that is pumped presents little to no risk to the environment.

Watch VideoLearn how to perform daily maintenance on Unibloc PD500 Series Pumps Unibloc Pump has been a leader in positive displacement pump manufacturing for over 30 years. We were the first to offer an all stainless steel housing and base plate. We cast one piece that includes flanges to minimize the amount of parts that need FDA approval. Our dedicated engineers don’t stop working until a solution is created and the job is complete. We offer a variety of precision engineered, high-quality positive displacement pumps that fit a variety of applications in a multitude of industries. We are not the largest sanitary pump manufacturer out there, but we are the premier pump manufacturer with the most willing, ready and able staff to meet the toughest industry demands.

Watch VideoLearn how to perform daily maintenance on Unibloc PD602-677 Series Pumps Precision engineered from stainless steel, our PD 600 series of pumps house free-floating rotors containing no rotor bolts. Unibloc’s innovative pump design is suited for food processing applications requiring daily strip-down sanitation.

Watch VideoUnibloc Pump lobe positive displacement (PD) pumps set the bar with their dynamic gearbox foundation. These PD pumps offer a solid basis for consistency and precision and provide the broadest selection of sanitary pumping solutions. In this video, learn how to replace the double mechanical seal for PD450 (300-575 Series). About Unibloc Pump: At Unibloc Pump, we are proud to live up to our reputation of providing exceptional craftsmanship and an uncompromising commitment to customer service. Since 1984, Unibloc has provided the food and beverage, meat and poultry, pharmaceutical and more industries with precision-engineered sanitary pumps, strainers and valves to take on the toughest jobs. We are the premier designers of simple, easy-to-Clean-in-place (CIP) or Clean-out-of-place (COP) pumps that fight downtime, achieve a lower cost of operation and meet deadlines with confidence.

Watch VideoOh no! There are no results matching this filter combination.

Try another filter combination, or .