Unibloc Food Grade Pump | Innovative Food Pump Technologies

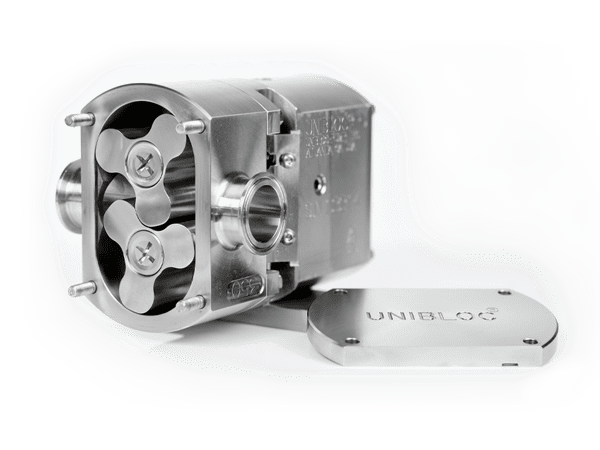

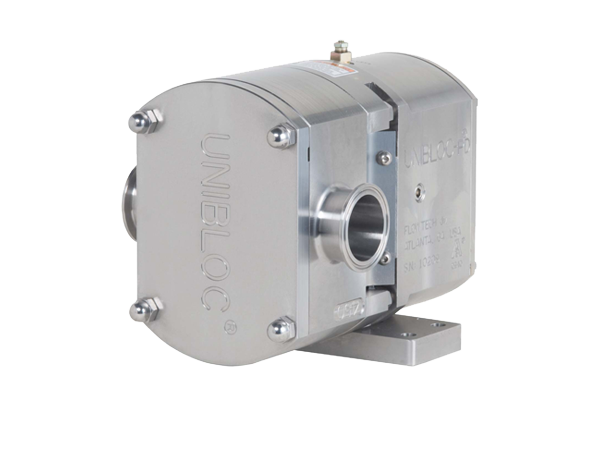

Unibloc has been a leader in food grade pump manufacturing for over 30 years. We pioneered the application of an all-stainless steel housing and base plate in our food pump. We were the first to cast one piece that includes flanges to minimize the number of parts that need FDA approval.

Innovation and engineering drive our product development and creatively solve challenges faced by the food processing, beverage, and pharmaceutical industries.

We offer a variety of precision engineered, high-quality food-grade gear pumps that fit a variety of applications in a multitude of industries. We are not the largest sanitary pump manufacturer out there, but we are the premier food product pump manufacturer with the most willing, ready and able staff to meet the toughest industry demands.

What Makes a Pump Food Grade?

Sanitary food grade pumps are designed to transfer consumable products between processes without exposing them to the mechanisms of the pump or other external exposure. Thanks to smooth pumping, these standard food-grade pumps gently transfer products without disrupting their consistency.

Food Grade Pumps aren’t limited to just the food industry. These high-quality pumps are designed to adhere to strict hygienic standards for use in the Pharmaceutical, Food, Beverage, and Cosmetics industries. The sanitary pumps we offer at Unibloc Pump are capable of handling a range of different applications. Find out below what sets Food Grade Pumps apart from the rest!

There are strict standards for food grade pumps, so not just the seals need to be sanitary, but the whole pump as well. The pump is constructed from Stainless Steel AISI 316L and finished with a high-grade finish.

When you purchase a pump, a certification from the FDA or EHEDG will confirm it was created to hygienic standards. In light of this, it’s important to emphasize that FDA-approved seals can be on the pumps but the rest of the pump is not, thus making the pumps unhygienic and not suitable for use in food-grade applications.

What is a Food Grade Pump?

Fluid is moved mechanically by cyclically enclosing and moving a fixed volume through the system using a positive displacement (PD) pump. This cyclic pumping can be achieved by pistons, screws, gears, rollers, or diaphragms.

There are a number of pump options, but most of them can be grouped into two categories: reciprocating and rotary.

Reciprocating Positive Displacement pumps are driven by cyclical strokes of a piston, plunger, or diaphragm. As opposed to reciprocating pumps, rotary positive displacement pumps move fluids with the continuous motion of gears, rather than the backward and forwards motion of reciprocating pumps. A liquid seal is formed between the rotating element and the pump casing, creating suction at the pump inlet. The pump draws fluid into the teeth of the rotating cogs or gears and transports it to the discharge. A gear pump is the simplest example of a rotary positive displacement pump.