Bakery and Confection Pumps

Our precision-engineered positive displacement pumps are made to handle a variety of materials and simplify large-scale processing without sacrificing quality.High-quality pumps are vital while working in bakery and confectionary processes. We understand professionals like you need pumping solutions that provide low-shear and consistent throughput to keep the processing line moving. The confectionery industry utilizes highly specialized and temperamental ingredients pumped safely and consistently. Abrasive additives and solid particles are common examples of substances that have a high viscosity and are particularly difficult to process. Selecting high-quality equipment to pump these components is essential. It is also vital to select equipment that complies with FDA regulations and global hygienic process standards, a crucial consideration in the baking and confectionery industries.

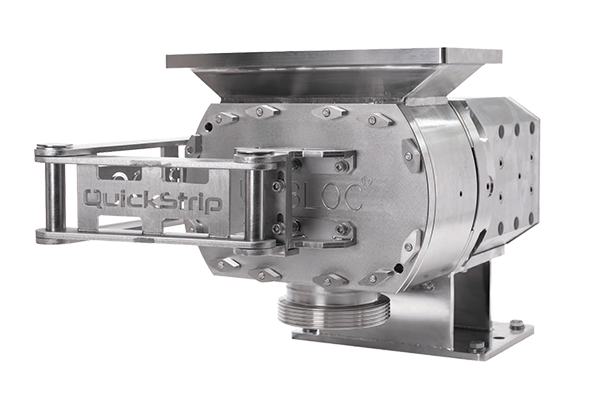

Our engineers work with bakery, snack food, chocolate, candy and confection aficionados to create hygienic pump system solutions for enhanced reliability, high performance and easy maintenance. The biggest challenge with chocolate is its abrasive nature due to sugar content. Chocolate tends to damage seals, so using a seal-free pump (AODD pump technology) is a good option – especially when the pumps are equipped with One Piece PTFE Faced Bonded diaphragms (Flotronic One-Nut AODD+ units) that are resistant to abrasion and have excellent heat deflection capabilities.

With hardened stainless-steel rotor options designed to handle abrasive and acidic applications, our lobe pumps have high clearance options to reduce shear, which allows for improved protection against over pressurization. Our pumps typically provide 5-35% more flow than other pump brands, allowing us to run slower for significantly improved life expectancies, reducing downtime and increasing your return on investment.

Features and Benefits

- Compact design down to 3/8″ for low/high accuracy applications

- Flat, crevice-free front cover that eliminates product dead zones

- Pump assemblies with 8″ capable of up to 500 gpm for high flow applications

- 5-35% more flow per revolution than the majority of our competitors

- Handles viscosities up to 1M cps

- Front-loaded shaft seal options

- Hardened wear sleeves

- Hardened stainless steel rotors for abrasive applications

- Metal and X-ray detectable plastic rotors for nightly hygienic applications

- FDA compliant

- 3A certified

- USP available

- Clean-in-place (CIP) capable

- Abrasive, viscous, temperature dependent products

- Modified pumps for the abrasion, learned through application experience

- Jacketed versions of the stainless-steel ranges

- Unique inside out design

- Jacketed options, especially good on chocolates and abrasive sugar applications

- Barrel unloading system for the higher viscosities

From the Blog

Innovative QuickStrip FoodFirst pump now available in all standard sizes

Unibloc Pump a US based Provider of Sanitary Flow Control Solutions Acquires Flotronic Pumps

Upcoming Events

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Explore Solutions

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

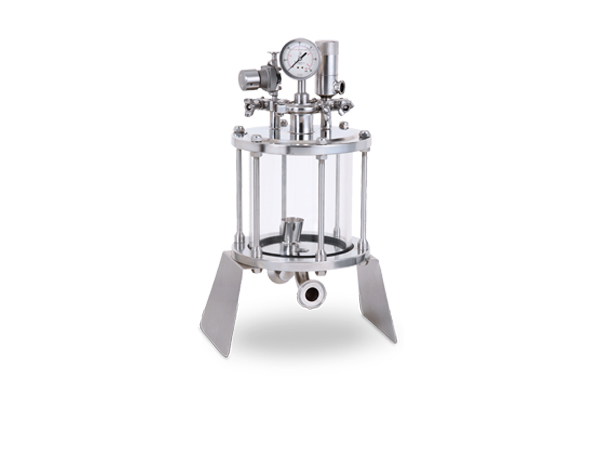

Providing a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBCs). Constructed from stainless steel and designed with Tri-Clamp® fittings, these pumps can be disassembled quickly for cleaning.

Designed for confined space applications in the food and beverage industries. Innovative, with easy mounting, pump motor alignment, smooth and quiet operation, and a small footprint.

Our barrel unloading systems combine our unique One-Nut hygienic/sanitary style AODD pump with our barrel unloading skid - allowing you to pump highly viscous materials at increased flow rates.

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut Pump meets your application requirements.

Customize your sanitary drum pump with a selection of accessories, including discharge spouts, pump hangers, discharge hose, and Tri-Clamp® fittings.

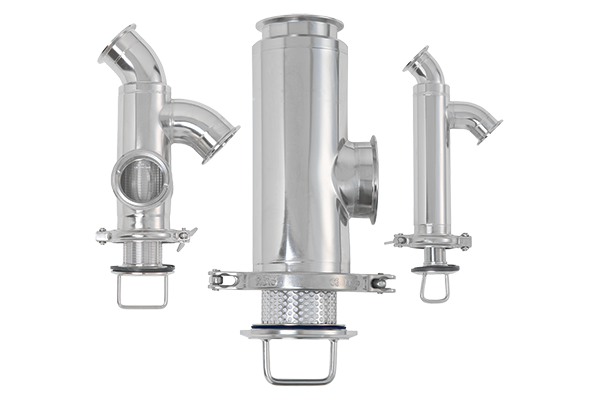

Engineered to remove pockets of air during the critical chromatography processes, our hygienic bubble traps feature an ultra-clean and installation-friendly design. We offer a wide array of sizes and port configurations.

Sanitary sight glasses, available in various sizes, glass materials and pressure ranges, give you extra efficiency and protection while supervising your active process.

Renowned for their durability and ease of cleaning, we proudly offer the widest selection of sanitary strainers in both standard and high capacity configurations.

View a complete selection of sanitary valves including pressure relief valves, check valves and butterfly valves.

Air-Operated Double-Diaphragm Plus Pumps

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs. These pumps are fully drainable, machined from solid materials of stainless steel or Hastelloy® and are perfect for hygienic applications.