- Compac Cart

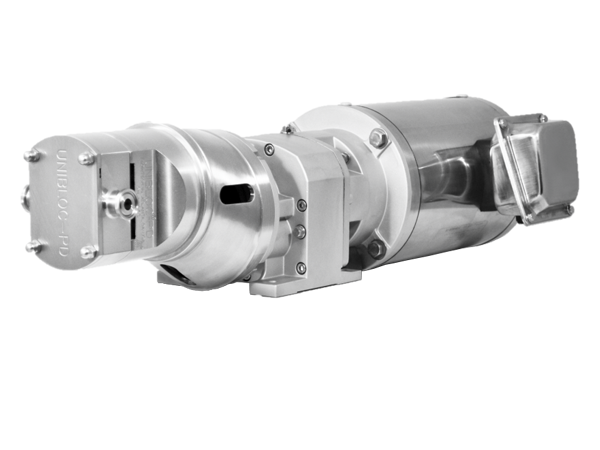

- Compac Flex Horizontal

- Compac Direct

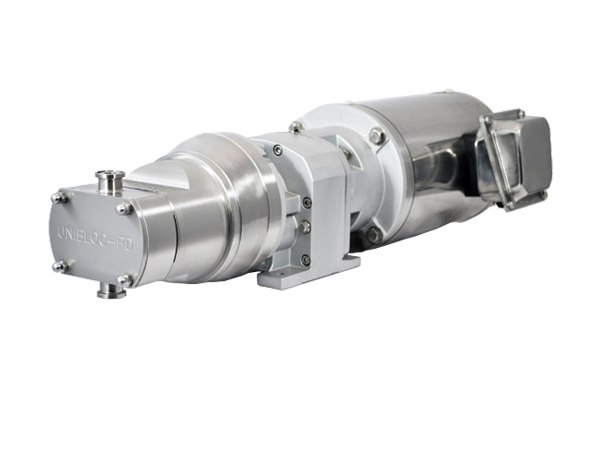

- Compac Flex Vertical

Compac Cart

Compac Flex Horizontal

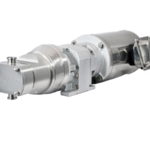

Compac Direct

Compac Flex Vertical

Unibloc® Compac Pumps

For restricted spaces and hygienic applications, the Unibloc® Compac® coupled pump solution is ideal. Offered in two versions – Compac Direct and Compac Flex – offering an innovative design, easy mounting, perfect pump motor alignment, smooth and quiet operation, and a small footprint.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

Key Features

- Horizontal or vertical mounting versatility

- Eliminates pump and motor alignment issues

- Quiet, low decibel operation

- Safe design with no accessible moving parts

Our Compac series of coupled pump solutions can be utilized for a wide range of applications in many industries. The innovative, patented design delivers a simplified, user-friendly pump system. From the unique, straightforward Compac Direct to the versatile Compac Flex, we offer lobe and gear pump solutions tailored to your specific needs.

HIGH PERFORMANCE AND EFFICIENCY IN A SMALL FOOTPRINT

With just four bolts for mounting the entire pump and motor assembly, the Compac design is ideal for OEMs seeking a small footprint to incorporate in their designs. Minimum assembly work is required, with just a few tools for easy mounting and integration. In addition, the Compac Series operates at high efficiencies.

FLEXIBLE OUTPUT AND MOUNTING APPLICATIONS – HORIZONTAL OR VERTICAL

The Compac Flex is designed with the pump mounted to a gear reducer on the motor, so the pump can be fine-tuned from 1200 RPM down to 60 RPM, whatever the application requires. And, the unit operates in either horizontal or vertical positions, making it even more flexible for the customer on the plant floor or for integrating the Compac Series into whatever the OEM might require. Simply remove the four bolts, turn it 90°, and mount with far fewer components than competitive pump designs.

ELIMINATES PUMP AND MOTOR ALIGNMENT ISSUES

The Compac Series avoids the bearing and pump failures associated with improper motor-pump alignment. The unit’s stainless-steel flange connects to the gear reducer for a perfect pump and motor alignment every time.

SAFE DESIGN WITH NO ACCESSIBLE MOVING PARTS

The Compac design considers more than just functionality, durability and versatility, but also safety. All moving parts are housed within the flange to prevent access to moving parts. No coupling guard is required with a Compac Series.

Brochures

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Complementary Products

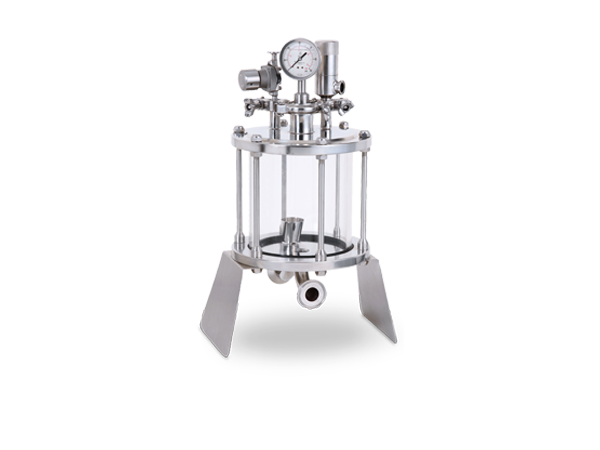

Bubble traps from Hygenitec have an ultra-clean, easy-to-install design that removes air pockets during vital processes. We offer a wide array of sizes and port configurations.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.

The two solid glass viewports on opposing sides of our 316L stainless steel Bulls-Eye sight glass enable the flexibility to position the equipment as needed.

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.