New Machining Technology to Boost Output 50-60%

KENNESAW, GA — (December 8, 2022) — Unibloc Hygienic Technologies, Inc. (UHT), a global leader in hygienic positive displacement pumps, AODD pumps, drum pumps, and other flow control products, has expanded production capacity at its Bolney, UK facility with a significant investment in additional machining technology. The investment continues UHT’s ongoing strategy of increasing production capacity to reduce production lead times and improve customer service.

UHT recently commissioned a new Matsuura H. Plus-405 PC12 horizontal CNC machining center. The Matsuura is a 12-pallet, four-axis machining center offering the capacity to replace three older machines with one, while increasing productivity. UHT selected this technology for its remote monitoring capabilities and advanced automation. The machine can run 24/7, allowing the facility to increase its capacity by 50-60% while occupying the same plant footprint as the previous machines.

“Our Bolney workforce consists of highly skilled CNC machinists,” said Chris Stevens, UHT CEO. “Adding this machine helps leverage their experience and knowledge while automating repetitive processes that are highly detailed and time-consuming. We selected the 12-pallet machine for its ability to stack work runs and then run autonomously. We will use the Matsuura to machine shorter-run custom parts during the daytime shift and then machine longer production runs during evenings and weekends.”

Councillor Howard Mundin, the Mayor of Haywards Heath Town Council and Councillor Victoria Hawken, the Vice-Chair of Bolney Parish Council, attended a ribbon cutting ceremony on December 7th.

“I’d like to congratulate Unibloc and their great local workforce on this major investment,” said Mayor Mundin. “It’s wonderful to see a progressive business like Unibloc, a pillar in our community, continuing to contribute to the area’s economic growth and technical development.”

UHT also recently invested in two new state-of-the-art lathes for the Bolney facility, with anticipated deliveries in January and June of 2023. The new equipment increases machining accuracy, speed, and reliability.

“Our ongoing investments enable us to adhere to a strategy of constant improvement that overcomes supply chain challenges and provides quick deliveries. Our focus centers on customer responsiveness coupled with the assurance they will receive the highest quality hygienic flow control equipment,” said Stevens. “Building our in-house machining capabilities helps us better serve our customers with great quality and industry-leading lead times.”

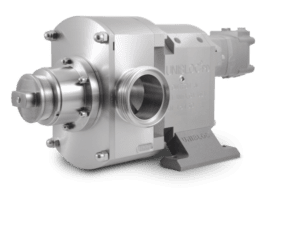

The Bolney facility is known as the location where the Flotronic ‘One-Nut’ Pump was pioneered, featuring a single-nut diaphragm design. This design significantly reduces process downtime by simplifying pump assembly/disassembly and providing savings in operating costs, along with best-in-class performance. The Flotronic One-Nut pump serves more than 1,000 companies worldwide, including iconic brands in food and beverage, consumer product goods, cosmetics, pharmaceuticals, and other critical process manufacturing operations. The workforce in Bolney has expanded by 15% in the last year and as capacity increases, the company anticipates adding more staff.

Click here for a high resolution image of the machine.

About Unibloc Hygienic Technologies

An industry leader in flow control technology and performance, Unibloc Hygienic Technologies offers precision-engineered positive displacement pumps, AODD pumps, drum pumps, and other highly engineered products for demanding hygienic flow control applications. UHT serves a variety of hygienic industries, including food, beverage, bakery/confection, meat and poultry, brewery, pharmaceutical, and transportation, under the Unibloc, Flotronic, Standard Pump, and Hygenitec subsidiary brands. UHT’s highly efficient, easy-to-maintain products help customers fight downtime, achieve a lower cost of operation, and meet deadlines with confidence. Learn more at www.unibloctech.com.

Founded in 1984, UNIBLOC-PUMP, has been a pioneer in the industry worldwide for Sanitary Pumps, Strainers and Valves. Our goal is to continue to offer the highest quality and newest innovations for a growing market. As our company grows we have kept customer satisfaction and business success in the forefront of our decision making.

Founded in 1984, UNIBLOC-PUMP, has been a pioneer in the industry worldwide for Sanitary Pumps, Strainers and Valves. Our goal is to continue to offer the highest quality and newest innovations for a growing market. As our company grows we have kept customer satisfaction and business success in the forefront of our decision making.