Hygenitec™ – Hygienic Flow Control Products Customers Rely Upon

Our newest brand of flow control products – Hygenitec™ – offers customers precision-engineered hygienic pumps, valves, strainers, bubble traps, sight glasses, and other process components. Our Hygenitec product line provides a wide range of flow management solutions that ensure top performance from your process system and are designed to help you fight downtime. As with all of our product lines, each Hygenitec product meets the daily demands of any production process line and is built on quality, precision, and innovation.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.

Hygenitec™ Pressure Relief Valves

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Our In-line strainers showcase simplicity with clean design and direct flow. They easily support tight or narrow spaces. Zero dead leg and fewer parts promote ease in disassembly and cleaning.

Hygenitec™ Bulls-Eye Sight Glasses

The two solid glass viewports on opposing sides of our 316L stainless steel Bulls-Eye sight glass enable the flexibility to position the equipment as needed.

Hygenitec™ In-Line Sight Glasses

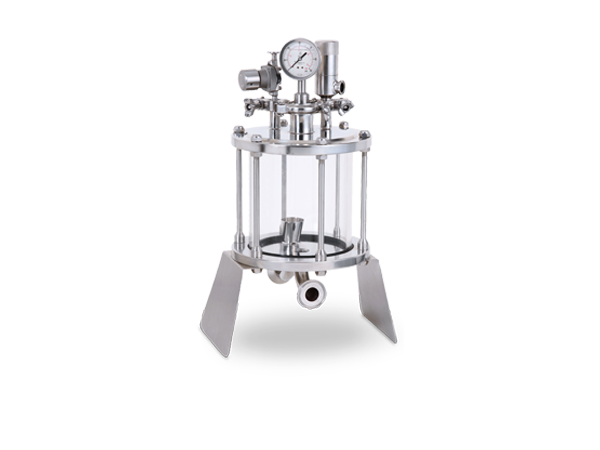

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.

Bubble traps from Hygenitec have an ultra-clean, easy-to-install design that removes air pockets during vital processes. We offer a wide array of sizes and port configurations.

Sanitary Drum Pumps provide a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBC’s).

A wide variety of hygienic pump tubes to support all of your liquid transfer needs for both low and high viscosity applications. The pump tubes adhere to stringent safety standards set forth by 3A and the FDA.

Hygenitec™ Drum Pump Accessories

Customize your sanitary pump with a selection of accessories including Discharge Spouts, Pump Hangers, Discharge Hose and Tri-Clamp® fittings.

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

A Wide Variety of Hygienic Flow Management Solutions

With a reputation for providing exceptional craftsmanship and an uncompromising commitment to quality, our Hygenitec product line tackles the toughest jobs while providing a superior product:

- Check valves and pressure relief valves designed for a variety of applications and crafted for easy maintenance

- Sight Glasses to provide clear views into your process

- Bubble Traps built with electropolished 316L stainless steel material and a wide variety of sizes and port configurations to fit your application

- Strainers designed with pharmaceutical grade quality with industrial strength durability

- Drum Pumps are constructed from stainless steel to provide safe and hygienic solutions for transferring ingredients from drums and intermediate bulk containers

- Oil Coolers for transport operations to ensure maximum performance during the long haul

Our Hygenitec line offers the exceptional service and support that comes standard with every Unibloc product line, including comprehensive documentation, material test reports, and surface finish certification, so our customers can count on Hygenitec’s rigorous quality control.

Quick Links

From the Blog

View BlogTwin Screw vs. Lobe Pump? Which Pump is the Better Choice for Suspended Solids?

As food processors respond to rising consumer demand for protein-enriched products, from high-protein yogurts to enhanced dairy beverages, production lines face increasing challenges with thick, viscous formulations. With the food processing automation market approaching $40 billion by 2030, the industry seeks equipment capable of handling complex products without compromising throughput or quality.

Read BlogComparing Hygienic Pump Technology Pros and Cons: A Process Engineer’s Guide

In hygienic processing environments, pump selection plays a far greater role than simply moving product from point A to point B. The pump directly influences product integrity, ensuring easy cleaning, reducing food safety risks, minimizing maintenance efforts, and lowering total cost of ownership. For process engineers working in food, beverage, personal care, or pharmaceutical applications, understanding which hygienic pump technology is best designed for each application is essential to building reliable, repeatable processes.

Read BlogChallenging Pump Applications, Meet Your Match

The ultimate guide to knowing when to use twin screw pump technology —don’t let viscosity slow you down

Read Blog