When it counts, count on Unibloc®.

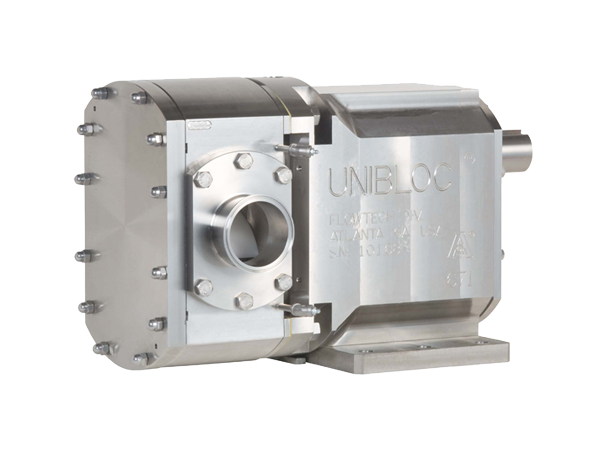

Unibloc brand pumps provide exceptional craftsmanship and an uncompromising commitment to easy maintenance and high reliability. Unibloc’s precision-engineered hygienic pumps have been found in the most demanding applications in the food and beverage, meat and poultry, pharmaceutical, and other critical industries to take on the toughest jobs. Its patented designs provide customers with quick and simple, easy to clean-in-place (CIP) or clean-out-of-place (COP) pumps that fight downtime, achieve a lower cost of operation and meet deadlines with confidence.

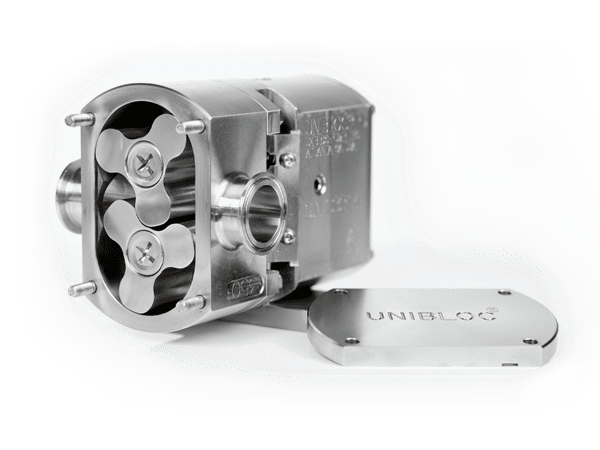

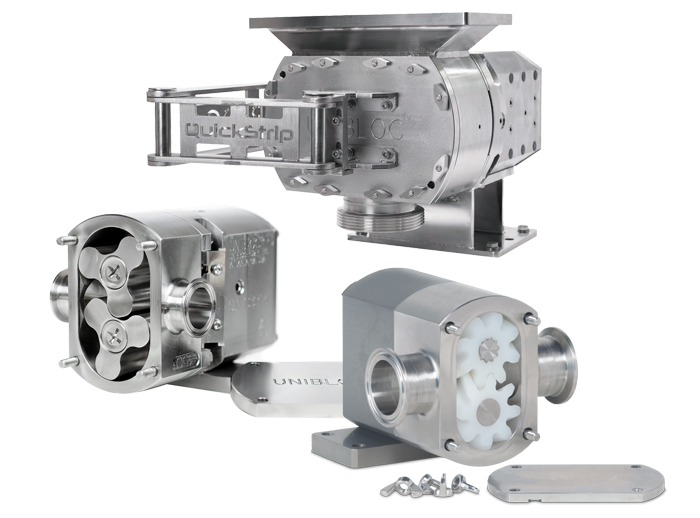

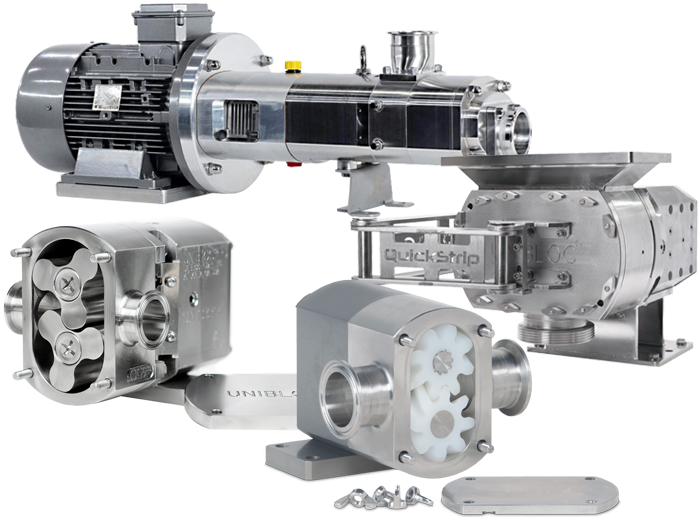

A fully machined gearbox at its core, this lobe pump sets the highest industry standards for performance, providing sanitary solutions for a variety of applications.

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications.

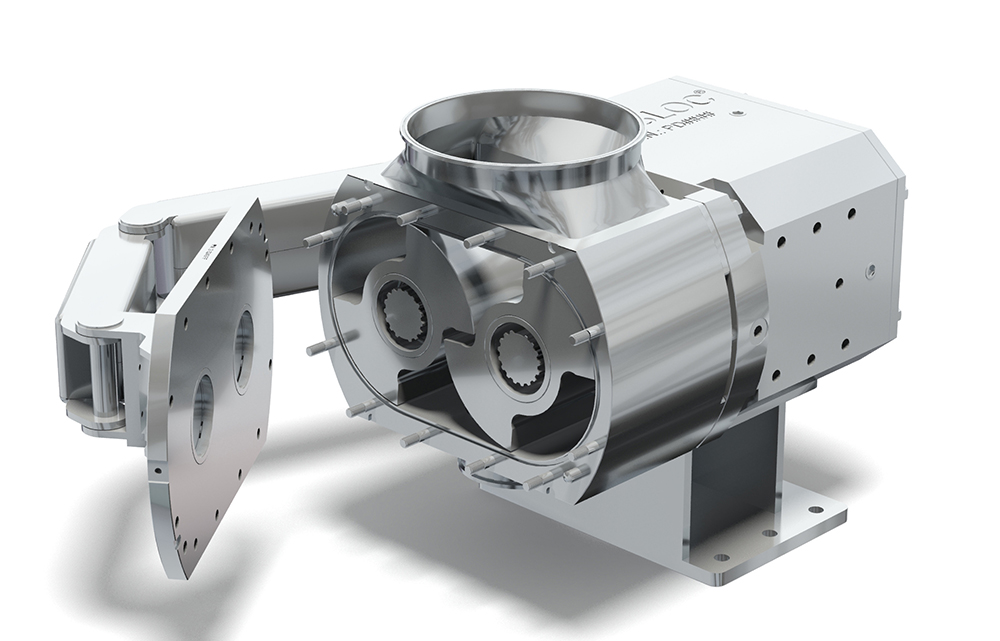

Unibloc® Twin Screw Hygienic Pumps

Finally, a Twin Screw Hygienic pump that delivers what ordinary twin screw pumps can’t: Less downtime. Less complexity. More performance.

For restricted spaces and hygienic applications, the Unibloc® Compac® coupled pump solution is ideal. Offered in two versions – Compac Direct and Compac Flex – offering an innovative design, easy mounting, perfect pump motor alignment, smooth and quiet operation, and a small footprint.

Looking for bigger and better? The Unibloc® UltraLobe™ FoodFirst® 700 Series Pumps answer that quest with a lobe pump that possesses all the qualities of our popular QuickStrip® FoodFirst 600 Series—and delivers more. Double or triple your throughput in a similar footprint to the 600 series. Maximize the ROI of every square foot of your plant space while preserving safety

Pumping tasks are simplified and streamlined thanks to our unique pumping solution. The compact, tabletop design of every LABTOP includes a Unibloc pump, motor, and controller housed in a stainless-steel canopy with bi-directional flow for added versatility.

The Unibloc transport oil cooler is a safe, robust centrifugal fan designed for maximum performance during the long haul.

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Precision Engineered for the Toughest Hygienic Pumping Jobs

Unibloc brand pumps have defined quality in positive displacement pumps with innovations that have quickly become industry standards in demanding food and hygienic applications:

- Seamless pump housings fully machined from solid steel

- QuickStrip® – tool-free disassembly and one-way re-assembly

- FoodFirst pump designs that feature the industry’s first patented Safety Swing Arm

Quick Links

Frequently Asked Questions

What is the flow rate of a Unibloc® pump?

Unibloc® pumps deliver flow rates ranging from 5 to 1,200 gallons per minute, depending on the model and series selected. The maximum flow rate of a Unibloc pump depends on the specific application, involving factors such as product viscosity, temperature, and internal friction of the system. Flow rate capabilities vary by pump type: our gear pumps excel in lower, controlled flows, while our Unibloc rotary lobe pumps provide high-volume transfer, even for delicate items like strawberries or large items such as chicken breasts. Our engineering team can help you select the right Unibloc pump configuration to match your exact flow rate needs while lowering your total cost of ownership.

How to calculate the maximum flow rate of a Unibloc pump?

Calculating the maximum flow rate of a Unibloc pump involves understanding displacement volume and operating speed. Start by identifying your pump's displacement per revolution, which is specified in our technical documentation for each model. Multiply this displacement by the maximum recommended RPM for your pump series to determine the theoretical maximum flow. However, actual flow rates depend on several factors: product viscosity, system pressure, temperature, and suction conditions, all of which affect performance. For viscous products, flow rates may decrease as the pump works against greater resistance. Our engineering team recommends operating Unibloc pumps within 80-85% of maximum capacity for optimal efficiency and longevity. This approach balances productivity with reduced wear on components.

Contact our application engineers with your specific product characteristics and processing requirements, and we'll calculate the ideal flow rate and pump configuration for your operation, ensuring reliable performance and minimizing total cost of ownership.

What is the total cost of ownership for a Unibloc pump?

The total cost of ownership for Unibloc pumps is significantly lower than competitive alternatives, thanks to our QuickStrip® technology. While initial purchase price matters, smart operators also consider maintenance costs, downtime expenses, energy consumption, and service life. Our patented QuickStrip design reduces maintenance time by up to 67%—technicians can strip and clean a lobe pump in 20 minutes versus an hour for traditional designs. Tool-free disassembly and one-way reassembly eliminate costly errors and speed up cleaning cycles. Our Safety Swing Arm reduces injury risk and workers’ compensation costs. Fewer parts mean fewer replacements and lower inventory costs. When downtime may cost thousands of dollars per hour, Unibloc pumps’ proven reliability and cost-saving design deliver substantial TCO savings that far exceed any initial price difference.

From the Blog

View BlogTwin Screw vs. Lobe Pump? Which Pump is the Better Choice for Suspended Solids?

As food processors respond to rising consumer demand for protein-enriched products, from high-protein yogurts to enhanced dairy beverages, production lines face increasing challenges with thick, viscous formulations. With the food processing automation market approaching $40 billion by 2030, the industry seeks equipment capable of handling complex products without compromising throughput or quality.

Read BlogComparing Hygienic Pump Technology Pros and Cons: A Process Engineer’s Guide

In hygienic processing environments, pump selection plays a far greater role than simply moving product from point A to point B. The pump directly influences product integrity, ensuring easy cleaning, reducing food safety risks, minimizing maintenance efforts, and lowering total cost of ownership. For process engineers working in food, beverage, personal care, or pharmaceutical applications, understanding which hygienic pump technology is best designed for each application is essential to building reliable, repeatable processes.

Read BlogChallenging Pump Applications, Meet Your Match

The ultimate guide to knowing when to use twin screw pump technology —don’t let viscosity slow you down

Read Blog