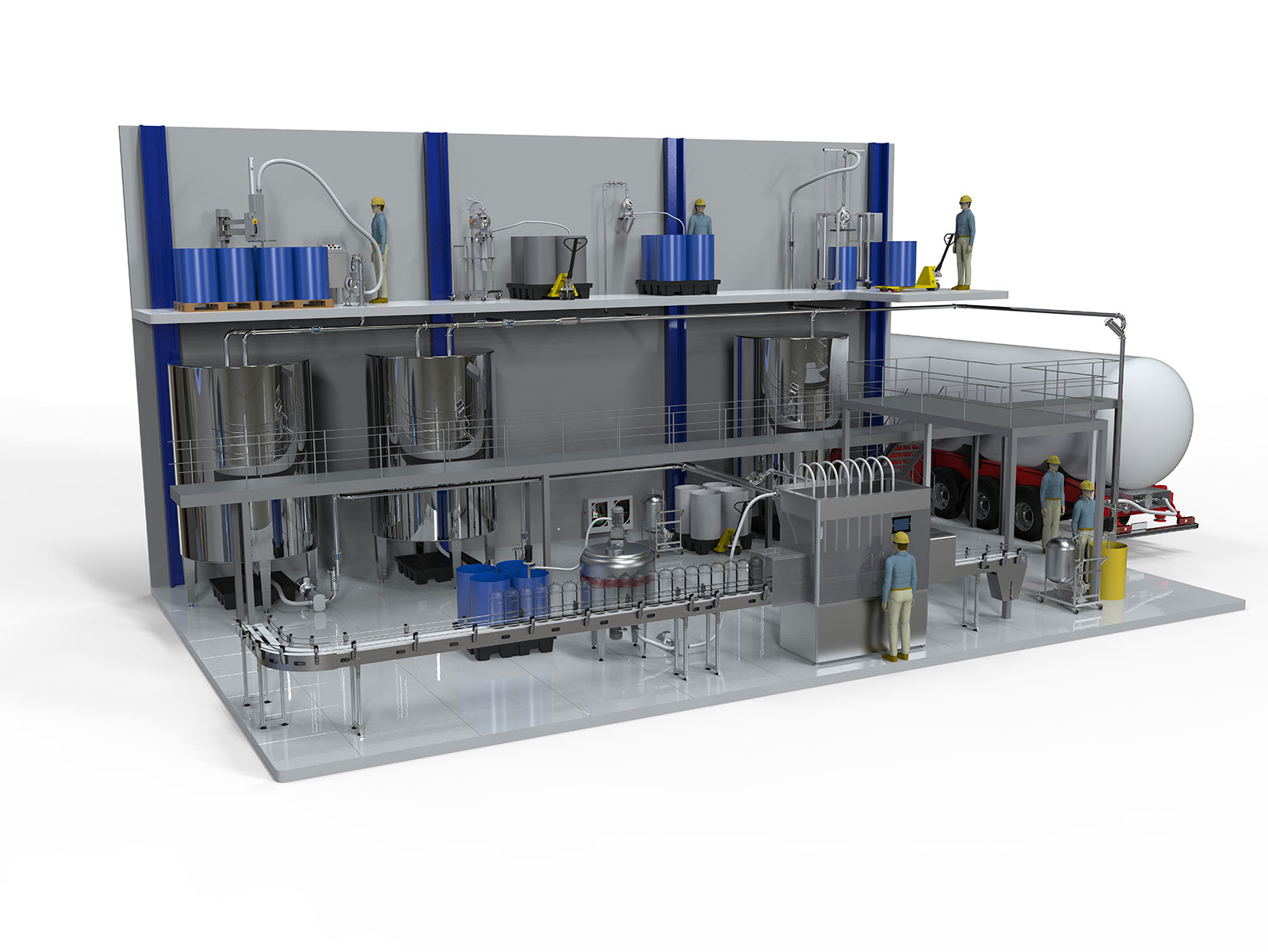

Unibloc Interactive Plant Graphic

The Interactive Processing Plant

Unibloc Hygienic Technologies Has You Covered from the Loading Dock through Processing

Select a marker on the image to learn more.

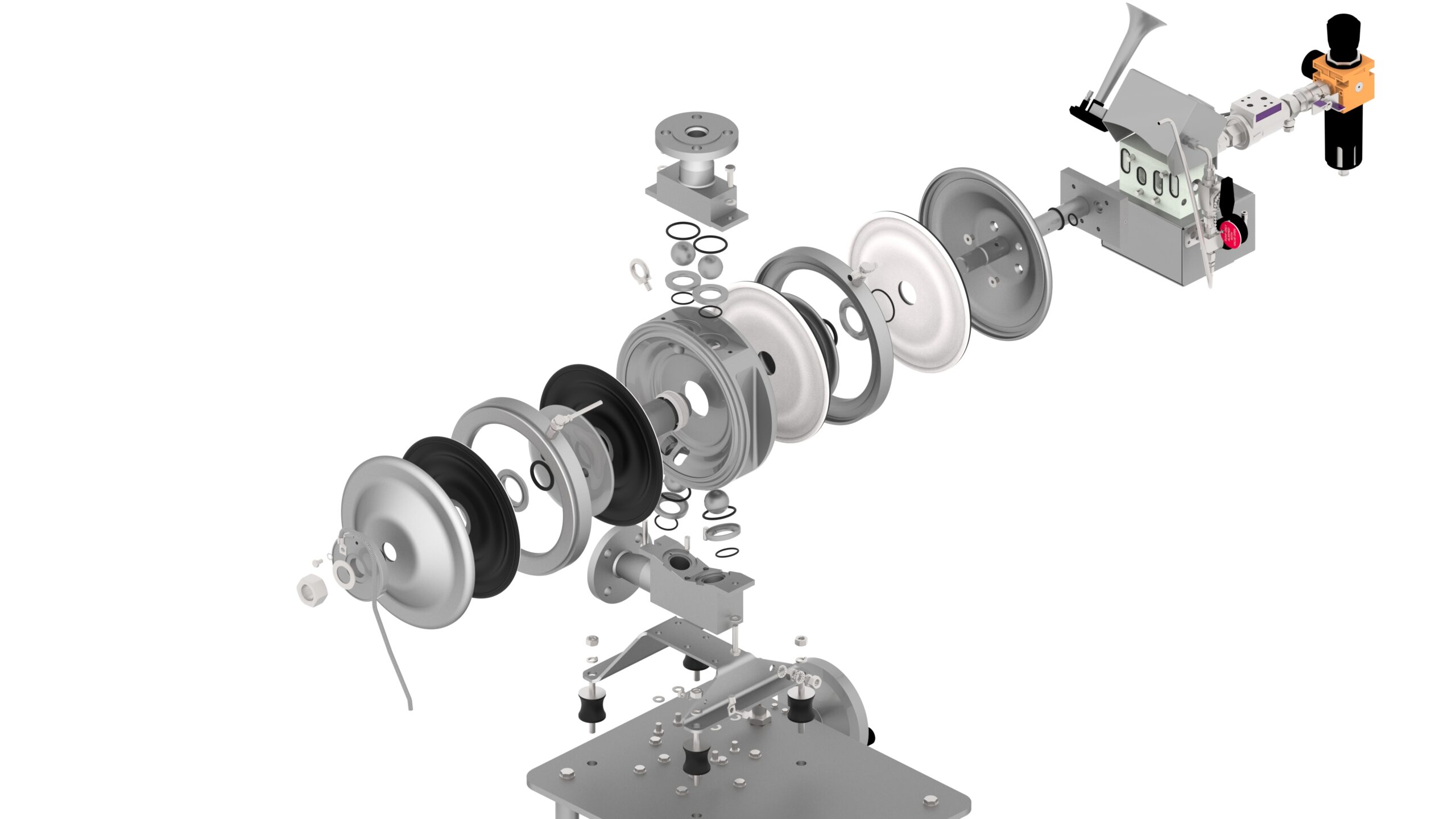

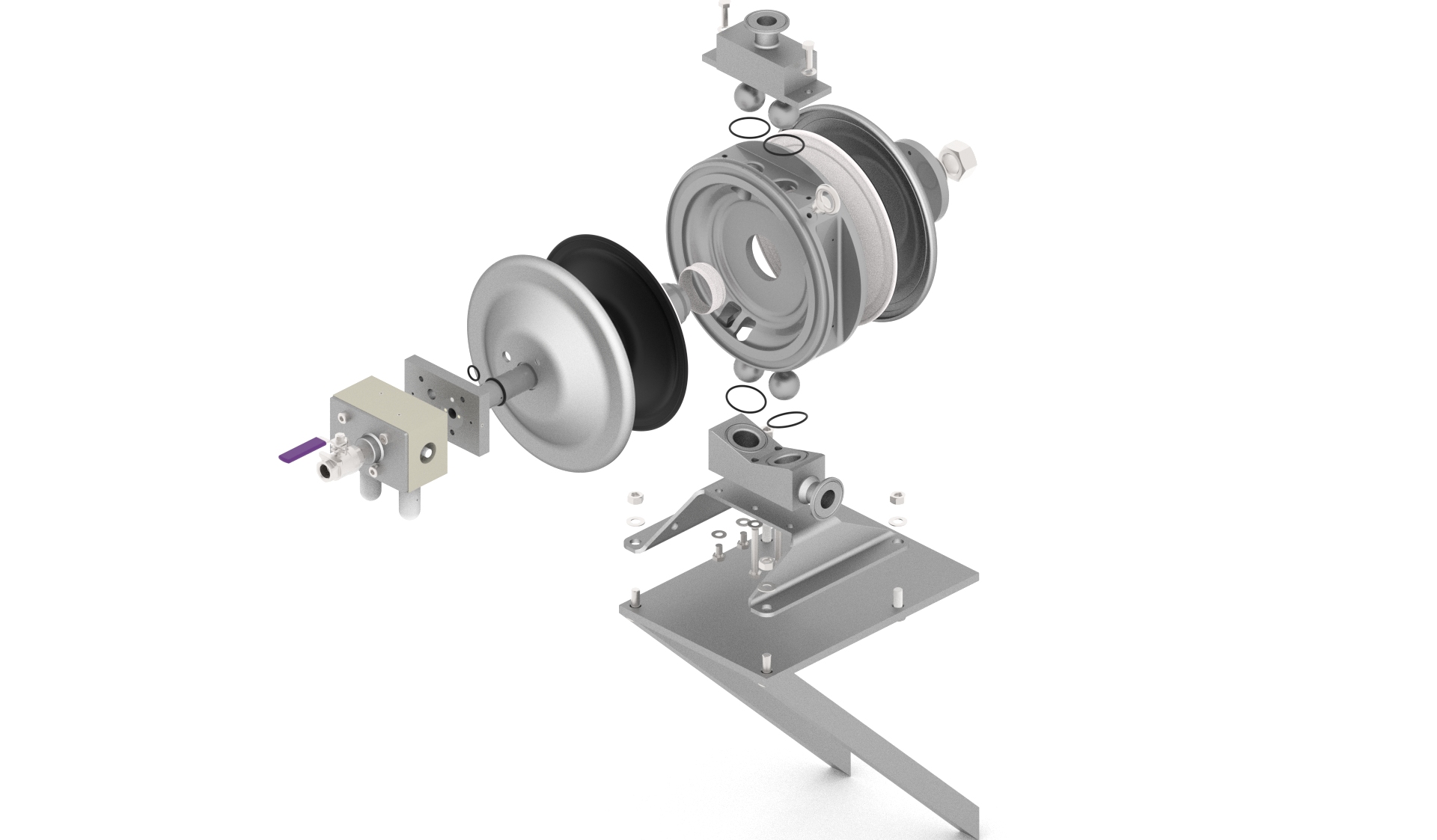

On the production floor, a 12-inch Flotronic® 3A sanitary slim pump occupies a small footprint as it moves product through the boom arm unloading system to the vessel on the level below. Designed to accommodate clean in place (CIP), the pump’s proprietary One-Nut® technology facilitates easy maintenance for food and pharmaceutical applications with stringent sanitary requirements.

A 10-inch slim Flotronic® One-Nut® sanitary slim pump offers production flexibility as a mobile solution when mounted on an adjustable rolling cart. Here it was positioned to empty a drum to the vessel below. Equipped with a Guardian alarm system, it supplies instantaneous protection to shut down the pump and contain the media in case a diaphragm ruptures.

A wall-mounted 10-inch slim Flotronic® pump frees up space for extra production in several ways; the wall mount frees up valuable floor space, its slim profile occupies minimal space, and it allows the plant design to place product pipework against the wall.

The Flotronic® Barrel Unloading Systems incorporate our unique One-Nut® hygienic/sanitary air-operated double diaphragm (AODD) pump with a barrel unloading skid. It can raise or lower the pump for easy changeouts and enables up to 99% recovery of highly viscous materials at increased flow rates.

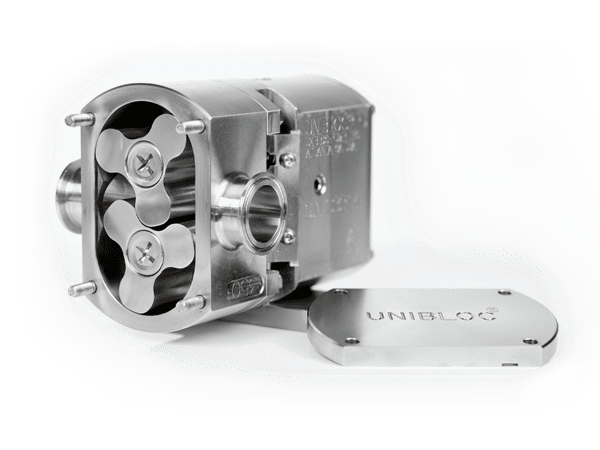

A premier choice for viscous materials in 3A sanitary applications, our gear pump series features precision engineered spiral cut gears for smooth, efficient and quiet operations. Our patented QuickStrip® Design allows tool-free access to pump heads and seals, reducing downtime and labor required for maintenance and sanitation.

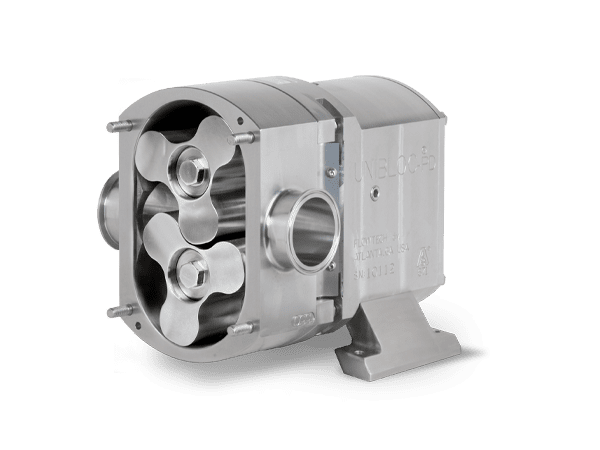

The two vessels contain a Unibloc PD550-Series Rotary Lobe Pump, which sets the industry standard for high performance sanitary pumps. It delivers smooth, low-shear performance that maintains product integrity for a wide range of challenging applications. Pumping pipework travels under the walkway into the back of the filling machine. Unibloc 550 pumps incorporate QuickStrip® technology with patented swing-arm design to cut maintenance time.

Tank transport professionals count on Unibloc Hygienic Technologies to provide rugged and reliable chemical and food-grade pumps. For over 35 years, Unibloc has refined our Road Tanker pumps to deliver dependability and longevity expected by trusted fleets.

Our Hygenitec sanitary drum pumps supplies a safe, efficient and hygienic method to transfer ingredients from drums and intermediate bulk containers (IBCs) to the next processing station.

We supply the strongest precision-built gear pumps in the industry, with every pump head comprised of solid 316L stainless steel. Here a gear pump is transferring product from the mixing vessel into the hopper. Spiral cut gears offer smooth, quiet operation. Our QuickStrip® design with one-way assembly mitigates damage from foreign materials for longer, durable service.

Sanitary in-line sight glasses are available in assorted sizes, glass material selection and pressure ranges, to allow safety and security while allowing visual supervision of the active process. Our double nut tensioning securely positions the sight glass without over-tightening.

In-line L Strainers are precision engineered to pharmaceutical-grade standards for operations that demand high sanitation levels. Available in 316L stainless steel or Hastelloy, in standard sizes or our high-capacity series, for higher flow rates, products with greater viscosities or companies looking for a solution for minimal pressure drop. Strainer customization allows a choice of strainer sizes and mesh options, with custom drain ports.

Our high-capacity hygienic Y-strainers are available in a wide array of line size options, from 0.75” to 6.0 inches. An in-line system allows workers to clean the strainer without removing it from the piping. Achieve desired versatility and volume with its bi-directional flow. The 360-degree equipment mounting choices help conserve space and allow greater flexibility.

Safely transfer corrosive chemicals such as those used in CIP and/or COP processes from drums, IBCs and Tote tanks with a Standard Industrial Drum Pump.

Our sanitary pressure relief valve features a straightforward, hygienic SimpleSet design which allows for easy pressure adjustment. Valves are available in a range of sizes and adjustable to pressures ranging from 10-200 psi. CIP design enables easy cleaning.

Unibloc truck pumps offer a reliable, food-grade pump engineered for rigorous daily loading/unloading. Easy to maintain. Industry's most dependable durable O-lip shaft seals prevent leaks.