Hygenitec™ Poultry Processing AODD Pump

The Poultry Processing pump was designed to transfer chicken tenders, disjointed wings, giblets and waste products. The pump features a unique Flap Check design which protects the integrity of the product. Available in vertical or horizontal configurations.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Key Features

- Flap Check Design

- Polished 316SS Wetted Components

- Tri-Clamp ® Intake / Discharge

- Choice of diaphragms

Looking For A New Approach? Look to our AODD+! Learn More

Hygenitec’s Poultry Processing AODD Pump can handle solids up to 3.8” (96.5mm). The pump features SS316 components, Tri-clamp® intake / discharge, and a choice of diaphragms. These pumps are designed to be quickly disassembled / assembled for pump maintenance and cleaning. Available with or without manifolds.

Applications

- Chicken

- Breasts

- Legs

- Feet

- Livers

- Hearts

- Necks

Brochures

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Models / Series

SPCP30SSE (3″)

- Transfers solids up to 2.46” (62.5 mm)

- Overmolded EPDM Diaphragms

SPCP30SSS (3″)

- Transfers solids up to 2.46” (62.5 mm)

- Santoprene Diaphragms

SPCP30SST (3")

- Transfers solids up to 2.46” (62.5 mm)

- Overmolded PTFE Diaphragms

SPCP40SSE (4″)

- Transfers solids up to 3.8” (96.5 mm)

- Overmolded EPDM Diaphragms

SPCP40SSS (4″)

- Transfers solids up to 3.8” (96.5 mm)

- Santoprene Diaphragms

SPCP40SST (4″)

- Transfers solids up to 3.8” (96.5 mm)

- Overmolded PTFE Diaphragms

SPCPNM30SSE (3″)

- Transfers solids up to 2.46” (62.5 mm)

- Overmolded EPDM Diaphragms

SPCPNM30SSS (3″)

- Transfers solids up to 2.46” (62.5 mm)

- Santoprene Diaphragms

SPCPNM30SST (3")

- Transfers solids up to 2.46” (62.5 mm)

- Overmolded PTFE Diaphragms

SPCPNM40SSE (4″)

- Transfers solids up to 3.8” (96.5 mm)

- Overmolded EPDM Diaphragms

SPCPNM40SSS (4″)

- Transfers solids up to 3.8” (96.5 mm)

- Santoprene Diaphragms

SPCPNM40SST (4″)

- Transfers solids up to 3.8” (96.5 mm)

- Overmolded PTFE Diaphragms

Pumping of flammable or combustible liquids can generate a static electric discharge, causing fire or explosion resulting in injury or death. Read and understand operating instructions before starting this unit. Follow all federal, state and local safety codes including NFPA 30 - NFPA77. Prior to connecting to air supply, install bond and ground wires and check continuity of each wire. A meter reading of one ohm or less is required for safe liquid transfer. Use only approved metallic pump tube, explosion proof or air motor, metallic drum and receiving vessel when pumping flammables. Air motors are not recognized under any current Underwriter’s Laboratory listing program. Consult a qualified engineer for suitability for use in a hazardous area or on flammables.

Complementary Products

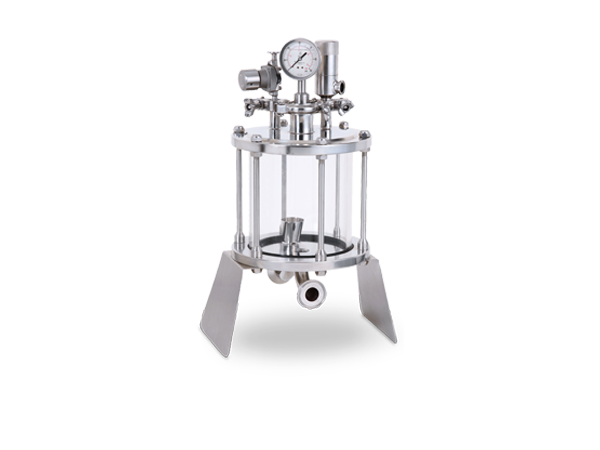

Bubble traps from Hygenitec have an ultra-clean, easy-to-install design that removes air pockets during vital processes. We offer a wide array of sizes and port configurations.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.

The two solid glass viewports on opposing sides of our 316L stainless steel Bulls-Eye sight glass enable the flexibility to position the equipment as needed.

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.