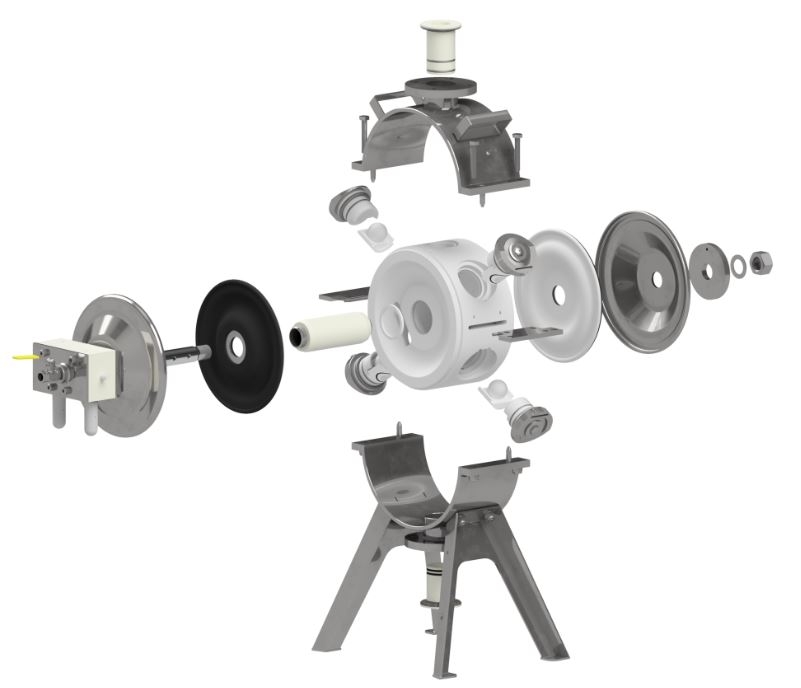

- Exploded View

- Exploded View - Full

- Chemflo PTFE Pump

Exploded View

Exploded View - Full

Chemflo PTFE Pump

Flotronic® Chemflo PTFE Pump

FDA Compliant PTFE AODD Pump machined from a solid block of Virgin or anti-static PTFE, housed completely inside a stainless steel casing, providing safe transfer of your hazardous liquids.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

Key Features

- Self-priming, suction lifts (3.6m/12ft dry and 8m/26ft wet)

- Can run dry

- Able to stop/re-start against closed/open valve without pressure relief or damage

- Ease of maintenance through Flotronic Pumps’ ‘One-Nut’ fast stripdown technology

- Easy air valve maintenance when pump is in-line

- A range of ½” to 3” connections

- ATEX Directive compliant up to Gas Group IIC

- Optional diaphragm rupture detection system with instant pump shut-down alarm facility to keep product contamination-free

- Optional high temperature diaphragm allows for a 135ºC (275ºF) maximum operating temperature

- Air valves available in Polypropylene, PTFE and Stainless Steel

- A range of connections include ANSI/DIN/BS flanges with PTFE raised face as standard. Other connections can be supplied on request

- Latest designs eliminate the costly internal air mechanisms normally associated with Double Diaphragm Pumps – and with no requirement for lubrication

- Material certification available on request (eg: 2.2 on wetted components).

THE IMPRESSIVE FEATURES AND BENEFITS OF THE CHEMFLO RANGE HELP YOU TO:

- Maintain levels of safety in hazardous environments and operations

- Reduce down time and cleaning costs

- Keep operations running and cost-efficient

Brochures

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

You may have tried an AODD. But that's nothing like a Flotronic® AODD+

Learn Why

CHEMFLO PUMPS – WHEN THE SAFE TRANSFER OF YOUR HAZARDOUS LIQUIDS IS PARAMOUNT.

The Chemflo range of PTFE Air-Operated Double-Diaphragm pumps have been specifically designed to handle your hazardous materials including aggressive chemicals. Crucial to the design is an outer Stainless Steel housing which supports and protects the main PTFE pump body which is machined from a solid block of PTFE / Teflon, through a range of pressure and temperature variations. This ensures a perfect seal is retained under all conditions.

Diaphragms are PTFE or TFM faced with Nitrile or EPDM backing, Balls and seats are all manufactured from USP Class VI and FDA approved PTFE or TFM.

All making the PTFE Chemflo Ideal for chemical, pharmaceutical and similar industries.

Flotronic’s unique One-Nut concept is particularly useful given the Chemflo’s likely applications. The One-Nut design of double diaphragm pump is a fast maintenance, fast Strip-down concept that turns the conventional pump inside out. Fluid passes between the diaphragms directly through the centre of the pump with air pressure operating on the outside. The pump is held together by one nut on the side opposite the external air valve.

‘One-Nut’ allows in-line inspection/replacement of diaphragms in less than 15 minutes. The outer metal housing is a further reason for the Chemflo’s extensive use in the chemical and pharmaceutical industries. Others include the Chemflo’s ability, as an Air-Operated Double-Diaphragm pump, to self-prime, dry-run, dead-head and handle solids.

Like all Flotronic pumps, the Chemflo can be customised to suit any application or location. With environmental protection in mind, Diaphragm Rupture Protection and fully pneumatic Alarm Systems can be fitted.

A range of accessories is also available including Pneumatic Pulsation Dampers and Batch Control Counters.

An optional 2 or 4 wheeled trolley with guide handle makes the Chemflo easily transportable.

APPLICATIONS:

- Chemical, pharmaceutical and similar industries

- Pilot plants (often in sampling lines)

- As emergency pumps for hazardous chemical recovery.

Complementary Products

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut pump meets your application requirements.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

The two solid glass viewports on opposing sides of our 316L stainless steel Bulls-Eye sight glass enable the flexibility to position the equipment as needed.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.