Hygenitec™ In-Line Sight Glasses

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

Key Features

- Double nut tensioning prevents over-tightening of the glass

- Electropolished stainless steel grid around the tube

- 304 or 316L stainless steel

- O-ring elastomers available in EPDM, Silicone of Viton

- 316L cone shaped strainer cartridge available in multiple mesh sizes – 3″ and up

- Polish up to 15 Ra and/or electropolishing

- Hastelloy-C and AL6XN material

- Elastomers of USP Class VI material

- Borosilicate glass available for temperatures 150 degrees F up to 550 degrees F

- Acrylic glass available

- Optional drain available

- Material test report available

The in-line sight glass consists of a glass tube compressed between two flanges, with a double nut tensioning to prevent over-tightening of the glass. It includes an electropolished stainless-steel grid around the tube as a safety precaution, and the standard sanitary connection of a Tri-Clamp. The in-line sight glass is ideal for efficient viewing while supervising your active process.

Brochures

Technical Specifications

2D Drawings

3D Models (STEP)

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Complementary Products

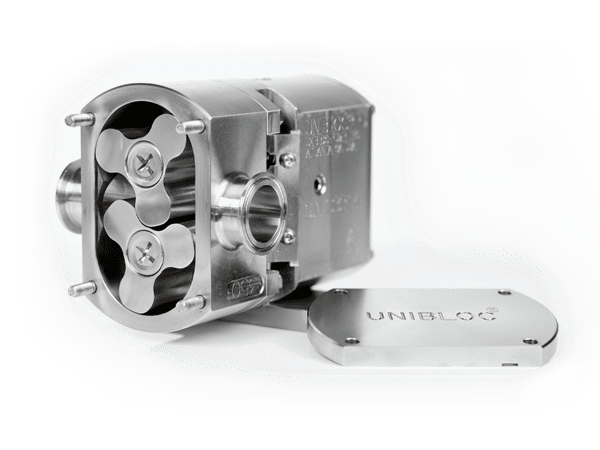

A fully machined gearbox at its core, this lobe pump sets the highest industry standards for performance, providing sanitary solutions for a variety of applications.

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications.

Designed with 3A in mind using FDA, USP Class VI and (EC) 1935/2004 approved materials; our range of Sanitary Diaphragm Pumps help maintain and improve hygienic conditions on your site.

710 Series Stainless Steel Pump

Fabricated 316L stainless steel or Hastelloy® on all wetted metal parts offers unrivaled versatility. These FDA compliant Air-Operated Double-Diaphragm Pumps are used extensively throughout the industry.

A compact and self-draining Diaphragm Pump available in FDA approved 316L stainless steel, aluminium, Duplex 22, and Hastelloy®; used in an array of industries.

Good Food Pump- Food Grade AODD Pump

Double Diaphragm Pump ideal for pumping your food products, especially on high viscosity low shear applications. Designed for ‘quick strip’ which is tool free or the pumps can be ‘cleaned in place’ (CIP), manufactured throughout from FDA compliant approved materials. The 'Good Food' pump gives food industry customers very specific benefits.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.