- 200 series

- 300 series

- 400 series

- 500 series

- 600 series

- Unibloc® UltraLobe™

200 series

300 series

400 series

500 series

600 series

Unibloc® UltraLobe™

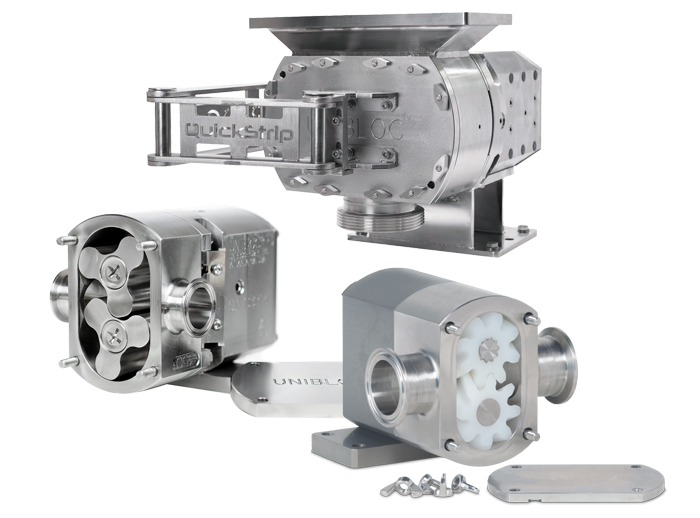

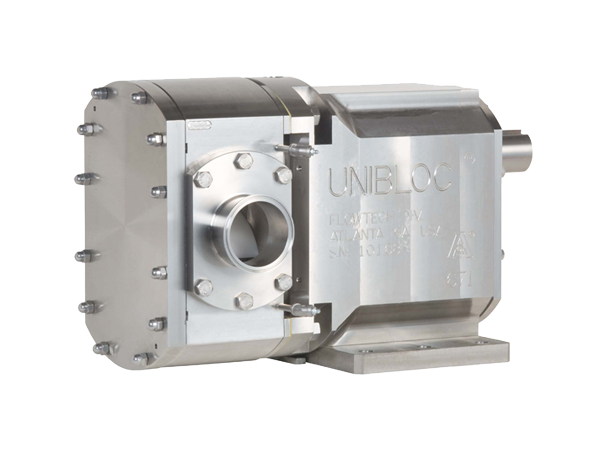

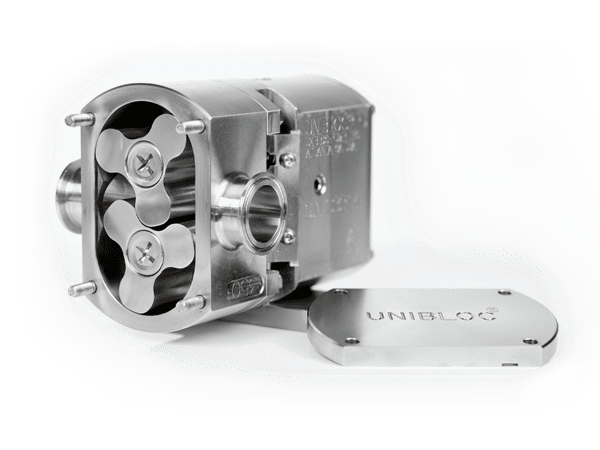

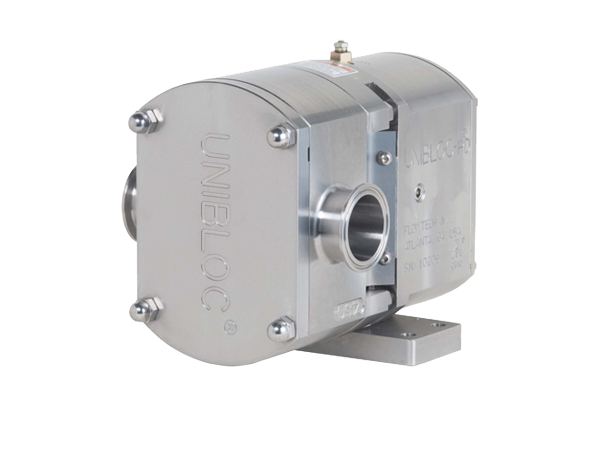

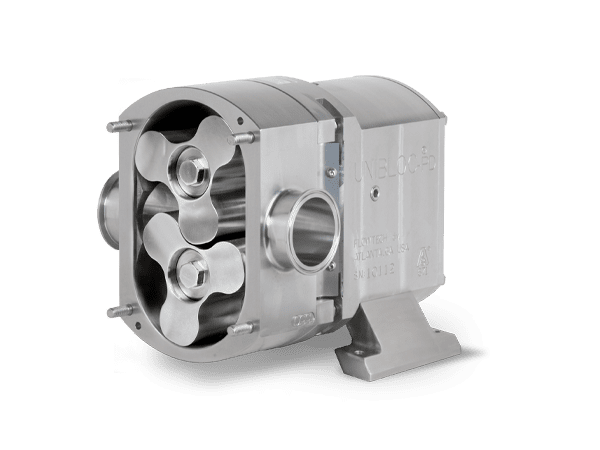

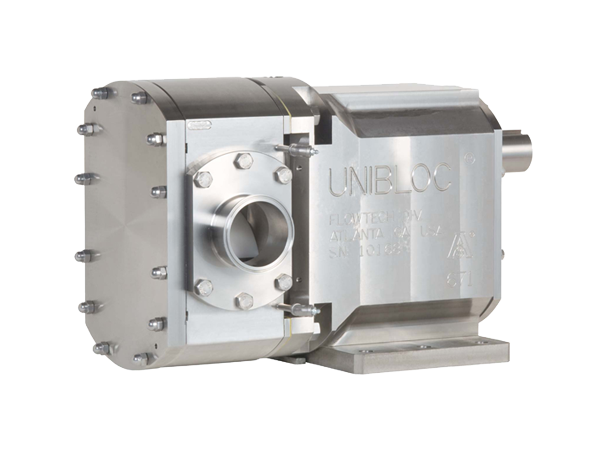

Unibloc® Lobe Pumps

A fully machined gearbox at its core, this lobe pump sets the highest industry standards for performance, providing sanitary solutions for a variety of applications.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

Key Features

- Ultra-hygienic design

- Patented rotor for low product shear

- QuickStrip® design for meticulous cleaning

Unibloc’s lobe positive displacement (PD) pumps set the bar with their dynamic gearbox foundation. These PD pumps offer a solid basis for consistency and precision and provide the broadest selection of sanitary pumping solutions.

Designed for the most rigorous processing and cleaning situations, Unibloc Pump is the leader in 3A sanitary applications.

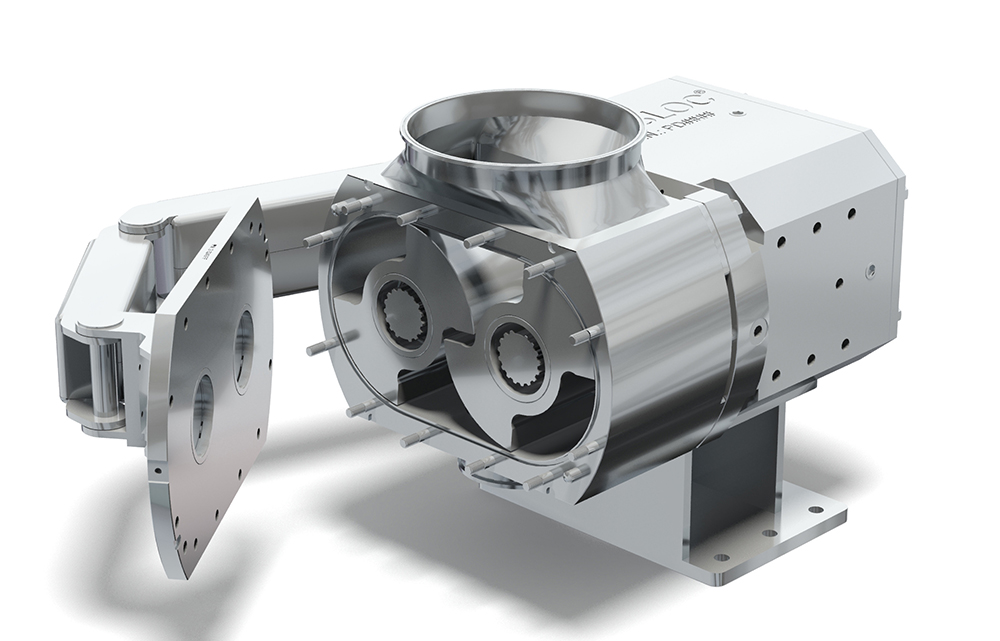

Patented Rotor Design

- Low-product shear and excellent displacement

- Tight, no-contact tolerances and optional non-galling alloy rotors mitigate the risk of foreign material and wear

QuickStrip® Design

- Engineered to meet FDA’s meticulous daily cleaning requirements

- Tool-free access to pump head and seals

- Available in both Lobe and Gear style pumps

- One-way assembly ensures accuracy and mitigates damage from foreign materials

- Optional front-loaded seal design – access to seals without detaching the pump head

Brochures

Manuals

Performance Curves

Parts Lists

2D Drawings

3D Models (STEP)

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

ULTRA-HYGIENIC DESIGN

Our seamless design and porosity-free guarantee exist for every pump we produce for the industry’s cleanest CIP/SIP capable pump. The sleek design eliminates any pinches or gaps that could build up material or conceal hazardous microorganisms. The gearbox has a non-stick exterior for easier cleaning.

SANITARY PUMP APPLICATION SOLUTIONS

- Ideal for high pressure, high-temperature applications, and low shear or abrasive products

- Versatile Seal Mount (VSM) technology allows seals to mount on any pump head with no modifications – simplifying operations with multiple applications

- Offered in an assortment of industry-specific materials and designs

- Rotor material options: stainless steel alloy, Polyflex® plastic metal detectable, and DuraCore® composite designs.

Frequently Asked Questions

Lobe pump life expectancy typically ranges from 5 to 12 years, depending on application severity, maintenance quality, and design robustness. Factors affecting longevity include product abrasiveness, operating pressure, temperature extremes, CIP chemical exposure, and maintenance consistency.

Unibloc® lobe pumps are engineered to exceed these expectations through our design philosophy and QuickStrip® technology.

- Our pumps feature a fully machined gearbox core that sets industry standards for durability and performance.

- Precision-machining from a solid billet of 316L stainless-steel provides superior strength compared to cast alternatives, resisting wear from aggressive sanitation and harsh processing conditions.

- QuickStrip® technology enables efficient preventive maintenance that extends pump life—technicians can inspect and replace wear components quickly, preventing minor issues from becoming major failures.

- Front-access seal replacement preserves critical tolerances that affect performance and longevity.

- Our one-way reassembly system prevents installation errors that accelerate wear.

- Fewer parts and simplified design reduce failure points.

When properly maintained, Unibloc lobe pumps are proven to deliver extended service life that minimizes total cost of ownership while maintaining the hygienic performance and reliability your operation demands.

Lobe pump limitations include relatively high initial cost compared to centrifugal pumps, lower efficiency with low-viscosity products, pulsating flow that may require dampening, and flow rates and head pressures lower than those of twin-screw pumps. However, Unibloc® Hygienic Technologies engineers have addressed many lobe pump limitations through innovative design.

Our lobe pumps feature optimized rotor profiles that minimize pulsation and improve efficiency. QuickStrip® technology dramatically reduces maintenance costs, improving total cost of ownership despite higher initial investment. Features like the patented Safety Swing Arm that enhance worker safety—lowering exposure to injury costs.

When gentle product handling, high pressure and flow with viscous products, self-priming capability, and hygienic design are priorities, Unibloc lobe pumps overcome traditional limitations to deliver superior performance and lower total cost of ownership.

Lobe pump flow rates vary widely based on rotor size, operating speed, and pressure conditions, with Unibloc® Hygienic Technologies models delivering from 3 to 500 gallons (11 to 19000 liters) per minute across our product range. Our mid-range PD350 model delivers up to 40 GPM (152 LPM) suitable for a broad range of applications, and our Unibloc® UltraLobe™ 700 Series provides high-volume flow up to 1170 GPM (4429 LPM) for demanding large-scale applications. Actual flow rates depend on product viscosity, system pressure, temperature, and pump speed.

Unlike centrifugal pumps that lose efficiency with viscous products, lobe pumps maintain consistent flow across wide viscosity ranges—making them ideal for everything from water-thin beverages to thick sauces and creams. Our engineering team can help you select the appropriate lobe pump size and configuration to achieve your target flow rate.

Complementary Products

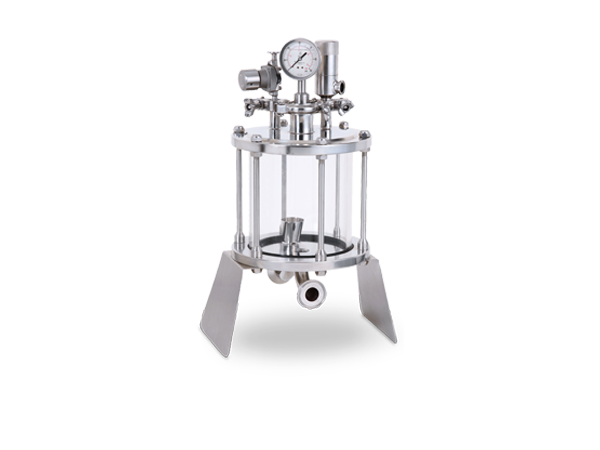

Bubble traps from Hygenitec have an ultra-clean, easy-to-install design that removes air pockets during vital processes. We offer a wide array of sizes and port configurations.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.

The two solid glass viewports on opposing sides of our 316L stainless steel Bulls-Eye sight glass enable the flexibility to position the equipment as needed.

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.

The Unibloc transport oil cooler is a safe, robust centrifugal fan designed for maximum performance during the long haul.