- GP 300

- GP 275 with Gearbox

- GP with Compac®

- GP 275

GP 300

GP 275 with Gearbox

GP with Compac®

GP 275

Unibloc® Gear Pumps

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

Key Features

- Ultra-hygienic design

- Precision-built bearing housing

- Compact design

- Smooth, quiet operation

- QuickStrip® design for meticulous cleaning

SAFER MATERIALS, ADVANCED ENGINEERING

Unibloc Pump gear positive displacement (PD) pumps set the bar with their dynamic gearbox foundation. These PD pumps offer a solid basis for consistency and precision and provide the broadest selection of sanitary pumping solutions.

Designed for the most rigorous processing and cleaning situations, Unibloc Pump is the leader in 3A sanitary applications.

Bearing Housing

- Strongest precision-built in the industry

- Available in both 316L stainless steel and anodized aluminum

- Solid 316L stainless steel comprises every pump head

Compact Design – Short/Stout Shafts

- Remove refraction at high pressures – leading to better productivity, improved current, and lengthier life cycle

- Reinforced jacket shafts are available for increased durability

Spiral Cut Gears

- Pulsation-free flow – smooth, quiet operation

- Compatible with servomechanical equipment – offering flow rates to precise specs

QuickStrip® Design

- Engineered to meet FDA’s meticulous daily cleaning requirements

- Tool-free access to pump head and seals

- Available in both Lobe and Gear style pumps

- One-way assembly ensures accuracy and mitigates damage from foreign materials

- Optional front-loaded seal design – access to seals without detaching the pump head

Brochures

Manuals

Performance Curves

Parts Lists

2D Drawings

3D Models (STEP)

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

ULTRA-HYGIENIC DESIGN

Our seamless design and porosity-free guarantee exist for every pump we produce for the industry’s cleanest CIP/SIP capable pump. The sleek design eliminates any pinches or gaps that could build up material or conceal hazardous microorganisms. The gearbox has a non-stick exterior for easier cleaning.

SANITARY PUMP APPLICATION SOLUTIONS

- Best for viscous material, such as fats, oils, and glycerin, that aid in smooth gear operation

- Versatile Seal Mount (VSM) technology allows seals to mount on any pump head with no modifications – simplifying operations with multiple applications

- Offered in an assortment of industry-specific materials and designs

- Rotor material options: stainless steel alloy, Polyflex® plastic metal detectable, and DuraCore® composite designs

- Gear material alternatives: Teflon/Stainless, Teflon, and various plastics

Frequently Asked Questions

Gear pumps excel in applications requiring precise, consistent flow and that need excellent viscosity handling. These positive displacement pumps deliver smooth, pulse-free flow ideal for metering, transfer, and processing applications across food, pharmaceutical, and personal care product operations. Key advantages include simple, rugged construction with few moving parts, self-priming capability that handles air entrainment, and moderate suction lift. Unlike centrifugal pumps that lose efficiency with viscous products, gear pumps maintain performance across diverse applications.

Unibloc® Hygienic Technologies (UHT) gear pumps handle viscosities ranging from water-thin to highly viscous while maintaining accurate flow rates. Their compact footprint conserves valuable floor space, while their quiet operation improves the working environment. Unibloc gear pumps combine these inherent advantages with our commitment to easy maintenance and product safety. Whether you're transferring cooking oil, pumping chocolate, or handling pharmaceutical ingredients, our pumps are proven to outperform.

Gear pumps require maintenance at a frequency based on operating conditions, product characteristics, and application demands. In hygienic processing environments, daily cleaning and sanitation are standard, with comprehensive preventive maintenance typically scheduled monthly or quarterly, depending on run hours and product abrasiveness.

Unibloc® Hygienic Technologies gear pumps are designed to be the easiest gear pumps to service, reducing maintenance times. Our patented QuickStrip® technology allows technicians to quickly access pump components without tools. Minimal parts, easy-to-access seals, and an easy-to-clean design all cut maintenance time significantly.

Regular inspection of gears, seals, and clearances prevents unexpected failures, and with Unibloc gear pumps, the inspections are straightforward and fast. The robust construction and fewer moving parts translate to longer periods between major overhauls. This reliability and ease of maintenance reduce total cost of ownership while maintaining the hygienic standards critical to your operation.

Gear pumps typically deliver 3 to 7 years of reliable service, although properly maintained Unibloc® Hygienic Technologies pumps usually exceed these expectations significantly. Life expectancy depends on operating conditions, maintenance quality, and design robustness. Common failure modes include rotor wear from abrasive products, seal degradation from chemical exposure or temperature extremes, bearing failure from inadequate lubrication, and housing damage from improper maintenance or foreign material. Cavitation, running dry, and exceeding pressure ratings accelerate wear dramatically.

Unibloc® gear pumps are engineered to combat these failure modes through superior design and materials. Our pump housings are machined from solid 316L stainless-steel, providing exceptional strength and wear resistance compared to cast alternatives. This robust construction resists damage during aggressive CIP procedures and daily sanitation. By addressing root causes of pump failure through intelligent engineering, Unibloc gear pumps deliver extended service life and reliable performance.

Complementary Products

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications.

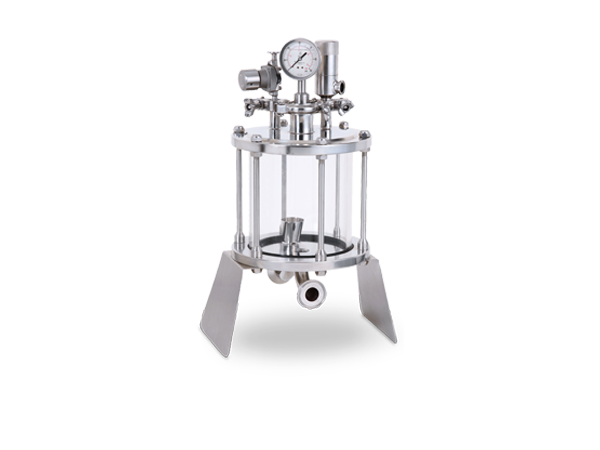

Bubble traps from Hygenitec have an ultra-clean, easy-to-install design that removes air pockets during vital processes. We offer a wide array of sizes and port configurations.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.

The two solid glass viewports on opposing sides of our 316L stainless steel Bulls-Eye sight glass enable the flexibility to position the equipment as needed.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.