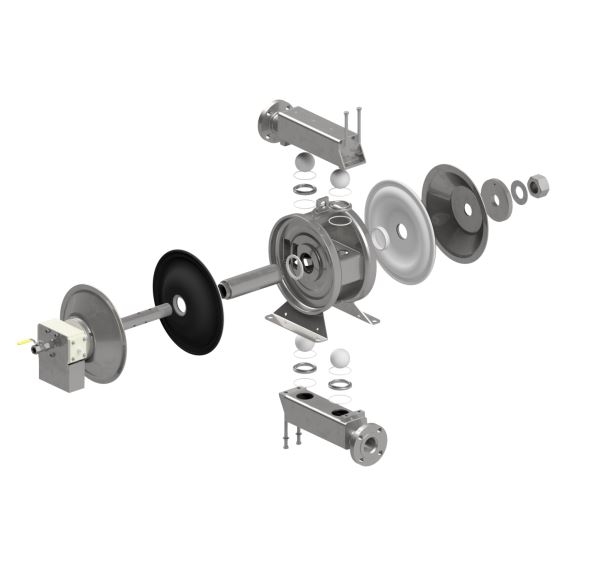

Flotronic® 710 Series Stainless Steel Pump

Fabricated 316L stainless steel or Hastelloy® on all wetted metal parts offers unrivaled versatility. These FDA compliant Air-Operated Double-Diaphragm Pumps are used extensively throughout the industry.

To Get Your Solution Started:

Request A Quote or Call +1‑770‑218‑8900

Book A Meeting

Key Features

- Compact design ideal when space is limited

- Outside surfaces can be easily cleaned

- A range of ½” to 3” connections, with 10”, 14” diameter diaphragms, providing in-line adaptability

- Screwed, hygienic or flanged connections to suit particular applications

- Ease of maintenance through Flotronic Pumps’ ‘One-Nut’ technology

- Readily accessible ball valves

- Pump air-valve easy to maintain when in-line

- A choice of materials, 316L Stainless Steel, and Hastelloy®

- ATEX Directive compliant up to Gas Group IIC

- Surface finish to customer specification available with a range of polished options

- Optional hot water/steam jacket

- With environmental protection in mind, Diaphragm Rupture Protection and fully pneumatic alarm systems are available

- Optional high temperature diaphragm allows for a 135°C (275°F) maximum operating temperature

- Self-priming 3.6m/12ft dry and 8m/26ft wet.

- Flow Rates up to 680 ltr/min.

This range of Air-Operated Double-Diaphragm pumps fabricated with FDA approved 316L stainless steel or Hastelloy® on all wetted metal parts gives our customers unrivaled versatility. Flotronic’s 710 range of diaphragm pumps can be used in a wide range of industries for any liquid transfer, including to pump chemicals, cosmetic, paints and coatings, pharmaceutical, adhesive, food and beverage applications.

They have proved particularly effective in the pumping of high viscous products such as cosmetics and foodstuffs including dairy products and mayonnaise.

Brochures

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

You may have tried an AODD. But that's nothing like a Flotronic® AODD+

Learn Why

Flotronic’s 710 pumps may be more compact than competitor AODD pumps, but they’re just as capable - offering all the benefits for which Flotronic pumps are renowned, including Flotronic’s innovative, easy-maintenance, ‘One Nut’ design of Air-Operated Diaphragm Pump which allows pump maintenance in a matter of minutes.

PERFORMANCE TO MATCH ANY REQUIREMENTS, ALL OF WHICH HELP YOU TO:

- Transfer an extensive variety of materials efficiently across a range of industries

- Reduce down time and cleaning costs.

- Ideal for applications such as chemical, cosmetics and personal care, paints, pharmaceutical, adhesive, hygienic, food and beverage.

Complementary Products

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut pump meets your application requirements.

Hygenitec strainers are precision-engineered to pharmaceutical-grade standards and are available in 316L stainless steel or Hastelloy, with in-line cleaning capabilities.

Y-strainers include an in-line system that allows workers to clean the strainer without removing it from the piping, assuring safety while also giving bi-directional flow and 360-degree equipment mounting choices.

Precision machined from solid stock, our butterfly valves accommodate a multitude of applications. A snap to install and maintain, these valves can be tailored with elastomer options and fully actuated versions to meet your individual demands.

Our SimpleSet design has made Hygenitec pressure relief valves the premier choice for over 25 years. Our hygienic pressure relief valves are fully adjustable with a multitude of pressure choices, combining versatility with an easy-to-operate design.

Check valves from Hygenitec are designed to guarantee effective, positive sealing. Our time-tested design featuring fully machined stainless housing and seamless ports confirms our commitment to sanitary design.

The two solid glass viewports on opposing sides of our 316L stainless steel Bulls-Eye sight glass enable the flexibility to position the equipment as needed.

Hygenitec in-line sight glasses are designed with a glass tube securely positioned between two flanges, with double-nut tensioning to prevent over-tightening, and an electropolished stainless steel protector around the tube as well as a standard sanitary Tri-Clamp connection.