Hygienic Pumps

Precision-engineered hygienic pumps, AODD pumps, drum pumps and more, from across our Unibloc, Flotronic and Hygenitec brands. All UHT hygienic pump products are built with the highest quality construction for proven reliability in the most demanding environments.

Unibloc®

The housings and bases of our positive displacement pumps are made of stainless steel. We cast one piece that includes flanges to minimize the number of parts that need FDA approval.

Hygenitec™

Providing a safe and hygienic solution for transferring ingredients from drums and intermediate bulk containers (IBCs). Constructed from stainless steel and designed with Tri-Clamp® fittings, these pumps can be disassembled quickly for cleaning.

Unibloc®

A completely hygienic, easy-to-clean pump is critical for pharmaceutical, biotech, and cannabis oil (CBD) applications. Our patented LABTOP pump series is simple and efficient with its “plug and go” design. This mobile solution is the perfect hygienic pump for filtration, chromatography, pilot applications, R&D and more.

Unibloc®

Designed for confined space applications in the food and beverage industries. Innovative, with easy mounting, pump motor alignment, smooth and quiet operation, and a small footprint.

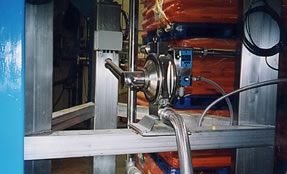

Flotronic®

Our barrel unloading systems combine our unique One-Nut hygienic/sanitary style AODD pump with our barrel unloading skid - allowing you to pump highly viscous materials at increased flow rates.

Flotronic®

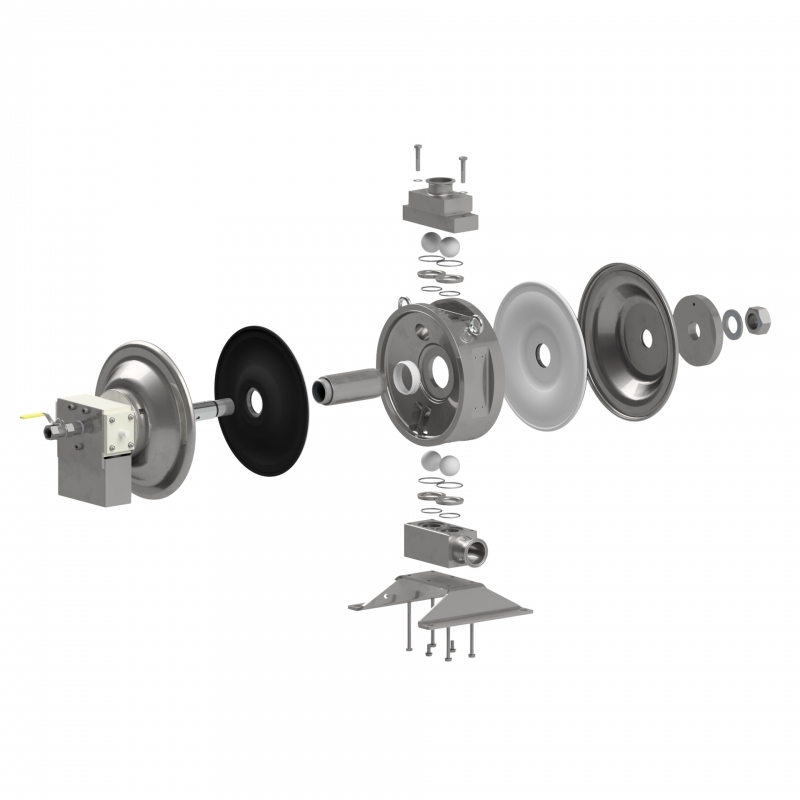

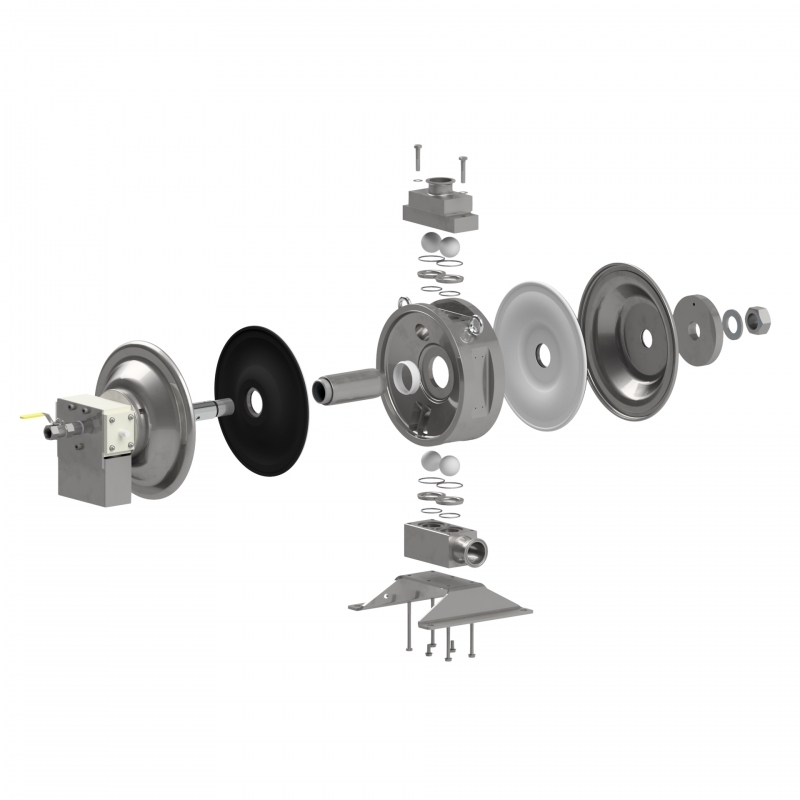

One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut Pump meets your application requirements.

Hygenitec™

Customize your sanitary drum pump with a selection of accessories, including discharge spouts, pump hangers, discharge hose, and Tri-Clamp® fittings.

Hygenitec™

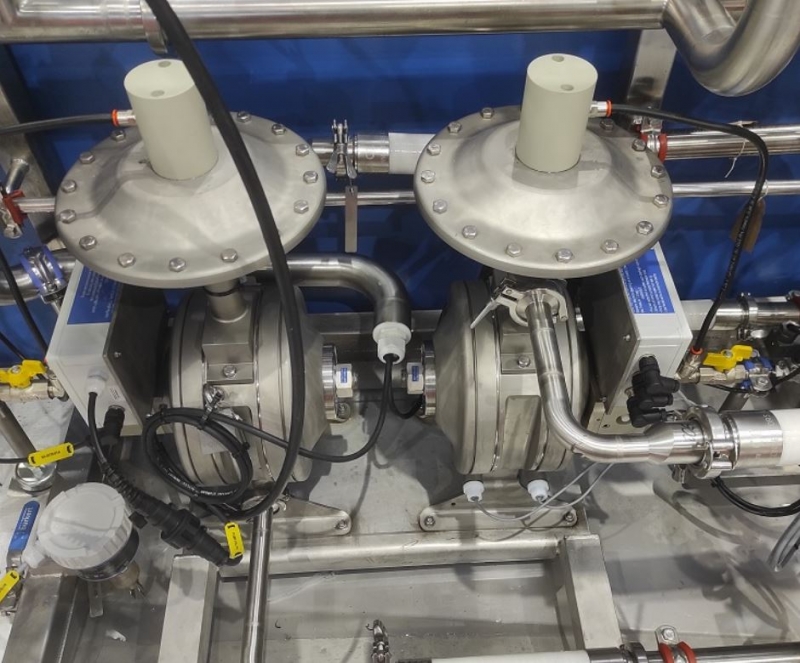

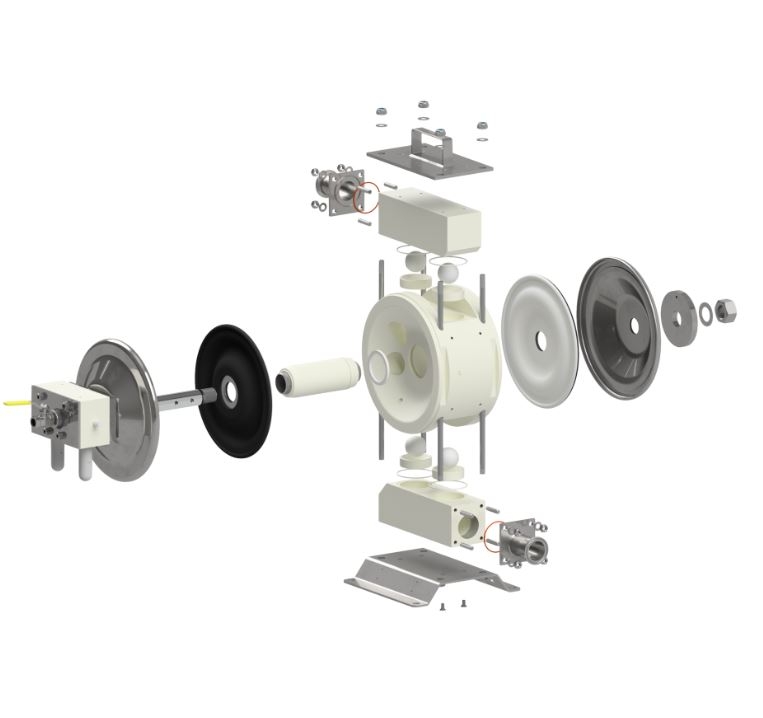

Air-Operated Double-Diaphragm Plus Pumps

Our hygienic range of diaphragm pumps offers a versatile and robust answer to your liquid transfer needs. These pumps are fully drainable, machined from solid materials of stainless steel or Hastelloy® and are perfect for hygienic applications.

Frequently Asked Questions

A sanitary positive displacement (PD) pump moves fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms, or vanes.

Although there are quite a few pump options, the majority can be placed into two categories: reciprocating and rotary.

A Reciprocating Positive Displacement pump works by the cyclical strokes of either a piston, plunger, or diaphragm. Rotary positive displacement pumps use the continuous motion of gears to move fluids, rather than the backwards and forwards motion of reciprocating pumps. The rotating element develops a liquid seal with the pump casing and creates suction at the pump inlet. Fluid is drawn into the pump and then enclosed within the teeth of its rotating cogs or gears and transferred to the discharge. The simplest example of a rotary positive displacement pump is the gear pump.

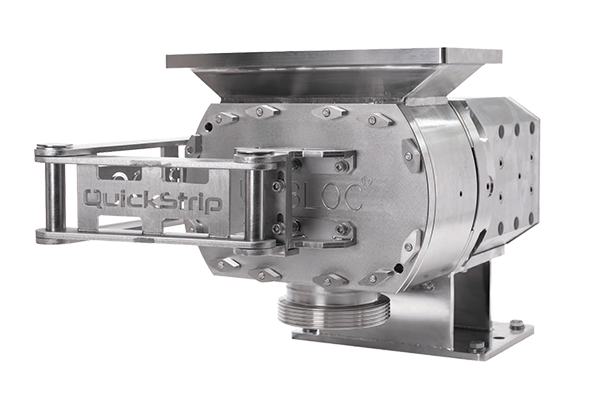

Hygienic pumps require a maintenance frequency that is based on application demands, product characteristics, and sanitation protocols. In food processing environments, daily clean-out-of-place (COP) or clean-in-place (CIP) procedures are standard, with deeper preventive maintenance typically performed weekly, monthly, or quarterly. Unibloc® hygienic pumps feature QuickStrip® technology that transforms maintenance on lobe pumps from a lengthy procedure into a rapid 20-minute task.

- The pumps feature tool-free disassembly and minimized parts to simplify maintenance. Pump seals are front-loaded and easily accessible, making seal replacement a snap.

- Parts are designed for one-way re-assembly. This eliminates worker errors that could lead to hygienic failures or foreign objects.

- When it comes to AODD pumps, only UHT offers the Flotronic®One-Nut® design that slashes maintenance from hours to minutes. This innovation eliminates extra pipework and enables a worker to access the pump internals by removing one large nut.

Industry standards and regulations mandate rigorous sanitation. With Unibloc Hygienic Technologies’ hygienic pumps, your team spends less time cleaning while maintaining the strict hygienic standards your operation demands.

Preventive maintenance for hygienic pumps involves scheduled inspections, cleaning, and component replacement. Regular preventive maintenance extends pump life, reduces emergency repairs, and prevents unexpected downtime that costs thousands per hour. Inspections include checking seals, examining wear components, verifying proper clearances, and ensuring all product-contact surfaces meet hygienic standards.

Unibloc® Hygienic Technologies’ hygienic lobe pumps with QuickStrip® technology make preventive maintenance remarkably efficient. Workers can replace seals without disassembling the rotor housing, preserving critical tolerances and preventing reassembly errors. With fewer parts to inspect and tool-free access, our Unibloc hygienic pumps transform preventive maintenance from a dreaded task into a quick, routine procedure that keeps your operation running safely and efficiently.

Maintenance schedules for hygienic pumps vary by application intensity, but typically they include daily sanitation, weekly inspections, and quarterly preventive service. Costs accumulate through labor hours, replacement parts, and production downtime—making efficient maintenance essential for controlling total cost of ownership.

Unibloc® Hygienic Technologies’ hygienic pumps dramatically reduce these expenses through intelligent design. The Unibloc QuickStrip® technology cuts maintenance time by up to 67%, meaning a 20-minute procedure instead of an hour. This time savings translates directly to labor cost reductions and faster return to production. It’s a similar story with our Flotronic® AODD+™ pumps, which can be disassembled, cleaned, and returned to service in 15 minutes versus 2 hours for traditional AODD pumps. It’s proven: our hygienic pumps deliver lower operating costs and better ROI over their lifespan.

From the Blog

View BlogChallenging Pump Applications, Meet Your Match

The ultimate guide to knowing when to use twin screw pump technology —don’t let viscosity slow you down

Read Blog6 Ways to Keep Hygienic Pumps Running Strong

Stop losing sleep over pump downtime, seal leaks, and maintenance headaches with these proven pump longevity strategies. The pressure is real—and it's not just in your pipes. Picture this: It's 2 AM, and your phone rings. Another pump leak. Another line shutdown. Another night of scrambling to keep production on track while costs spiral and your team burns out. Sound familiar?

Read BlogUnibloc® CleanPlus™ Industrial Pumps Are Lobe at First Sight

In the world of cosmetic, personal care, pharmaceutical, and chemical product processing, finding the perfect pump can feel like searching for your soulmate—you'll know it when you see it. Most industrial pumps demand constant attention, causing heartbreak when they inevitably let you down. At Unibloc® Hygienic Technologies, we've been listening. Introducing Unibloc® CleanPlus: a relationship designed to last, eliminate drama, and deliver the reliability you’ve been searching for. Our Unibloc CleanPlus line of hygienic lobe pumps offers smooth, dependable performance that keeps your operation running like a dream.

Read Blog