Flotronic®– Pioneering the One-Nut® Sanitary Air-Operated Double-Diaphragm Plus

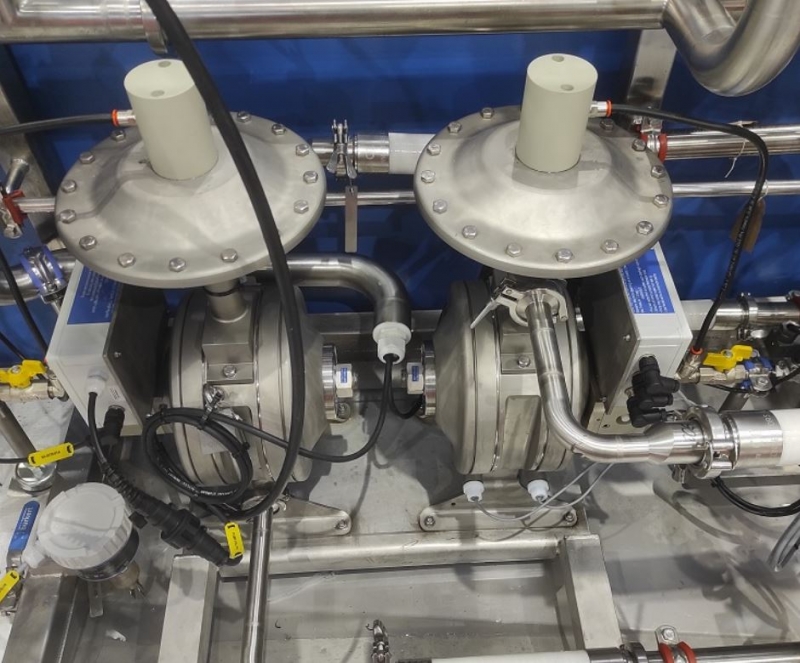

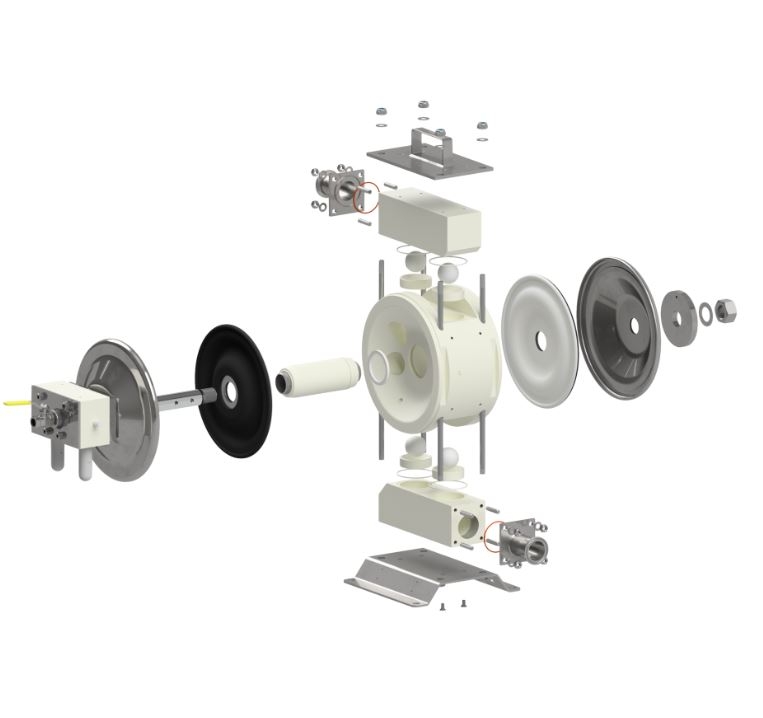

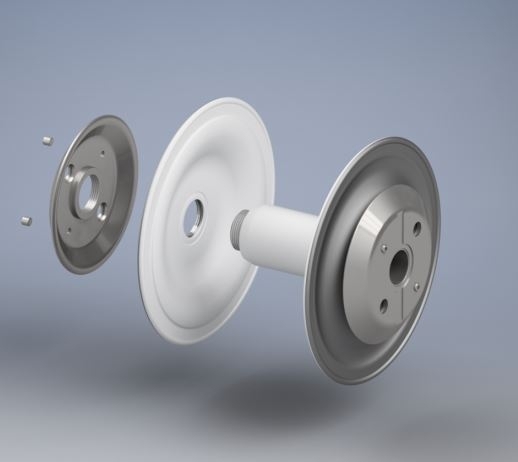

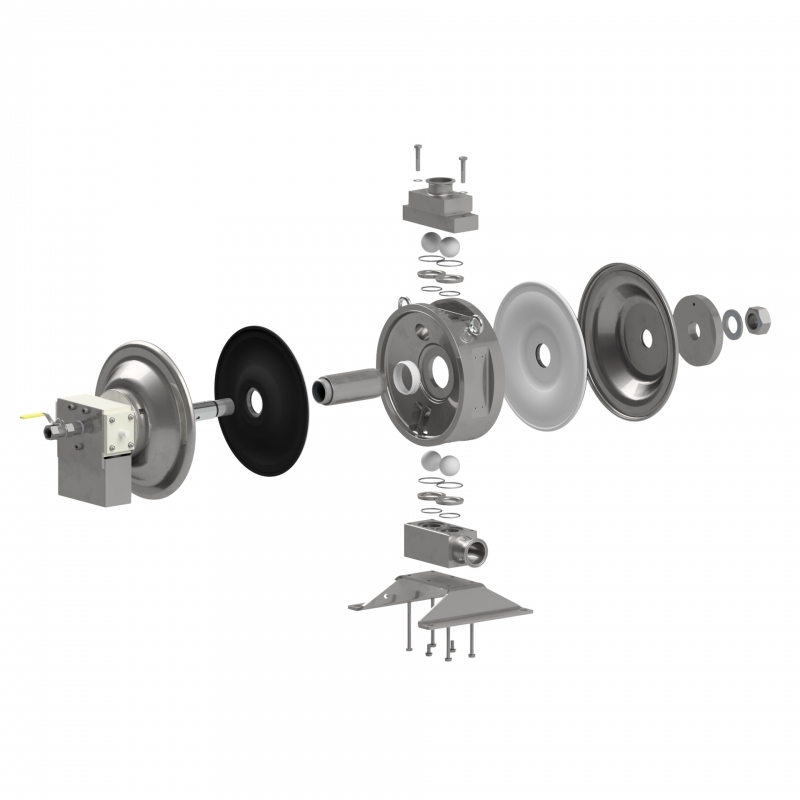

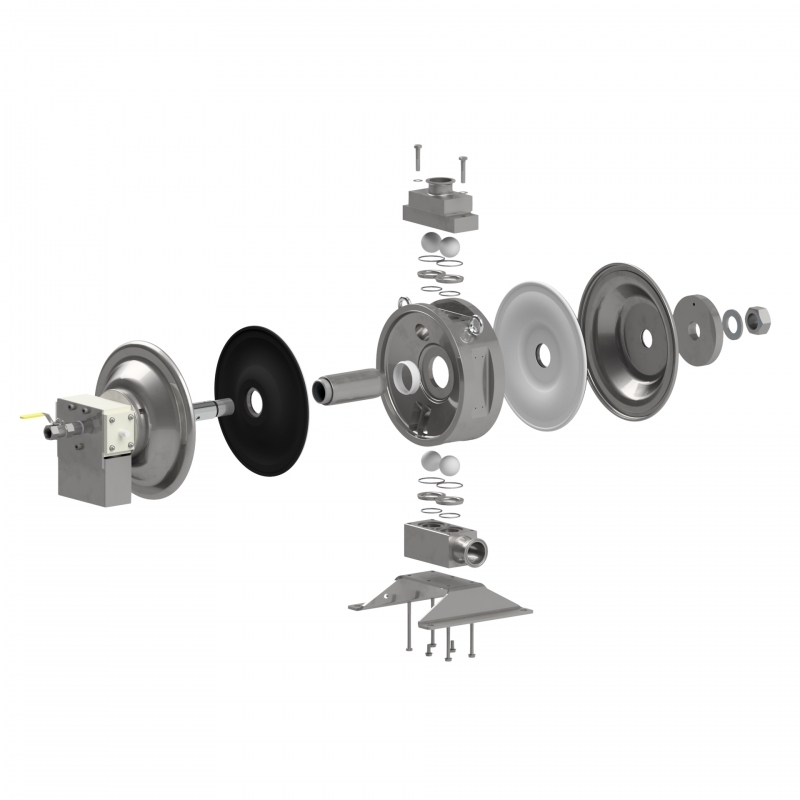

Flotronic® has made its name by developing its unique product, the One-Nut® Air-Operated Double-Diaphragm Plus (AODD+™). This pioneering design offers swift disassembly without disconnecting the pump from the process pipework.

Flotronic® One-Nut pumps can transfer a wide range of materials of varying degrees of viscosity and solids content. They can pump chemicals, adhesives, cosmetics, drinks, dyes, foodstuff, paints, pharmaceuticals and solvents. Our clients’ products are extremely diverse, ranging from industrial acids to hand creams and various food products.

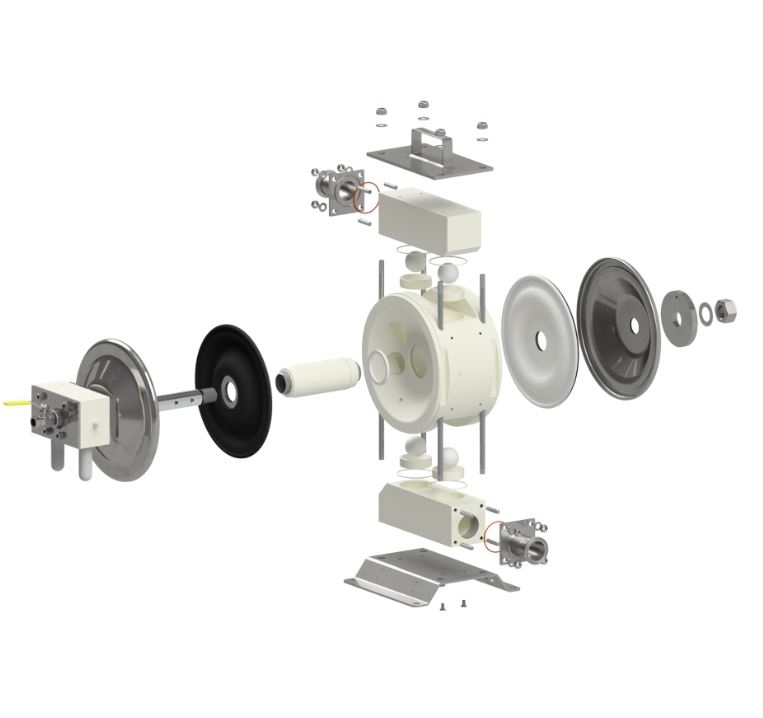

Flotronic® Good Food Pump- Food Grade AODD Pump

Double Diaphragm Pump ideal for pumping your food products, especially on high viscosity low shear applications. Designed for ‘quick strip’ which is tool free or the pumps can be ‘cleaned in place’ (CIP), manufactured throughout from FDA compliant approved materials. The 'Good Food' pump gives food industry customers very specific benefits.

A compact and self-draining Diaphragm Pump available in FDA approved 316L stainless steel, aluminium, Duplex 22, and Hastelloy®; used in an array of industries.

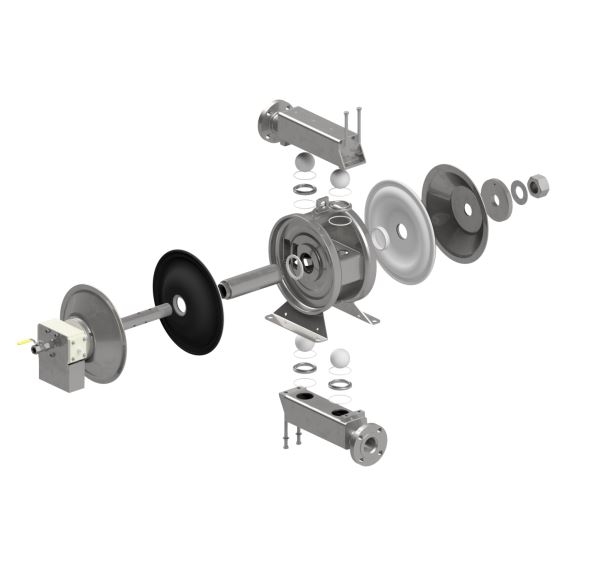

Flotronic® 710 Series Stainless Steel Pump

Fabricated 316L stainless steel or Hastelloy® on all wetted metal parts offers unrivaled versatility. These FDA compliant Air-Operated Double-Diaphragm Pumps are used extensively throughout the industry.

Flotronic® Sanitary AODD+ Pump

Designed with 3A in mind using FDA, USP Class VI and (EC) 1935/2004 approved materials; our range of Sanitary Diaphragm Pumps help maintain and improve hygienic conditions on your site.

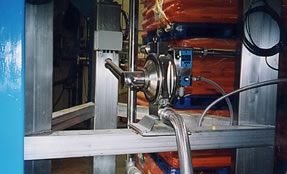

Flotronic® Barrel Unloading System

The Flotronic Barrel Unloading System combines our unique One Nut Sanitary Air-Operated Double-Diaphragm Pump with our Barrel Unloading Skid; perfect for high viscosities.

FDA Compliant PTFE AODD Pump machined from a solid block of Virgin or anti-static PTFE, housed completely inside a stainless steel casing, providing safe transfer of your hazardous liquids.

The Minichem is a totally unique design of FDA Compliant PTFE Double Diaphragm Pump machined from one solid block of PTFE, removing the need for separate manifolds.

Flotronic® 500 Series Plastic Pump

Unique Polypropylene / PVC plastic Double Diaphragm Pump design normally used for pumping / transferring solvents, acid or chemicals, often as a low cost option to stainless steel.

Flotronic® One-Nut Double Diaphragm Pump Accessories

A wide range of additional accessories and customization options to ensure your Flotronic® One-Nut pump meets your application requirements.

Looking to quickly compare the features and benefits of different pump styles, to find the right one for your application? The Unibloc comparison chart is a great place to start.

Hygienic Pump Comparison Chart

Supplying Sanitary AODD+™ Pumps to Industries Worldwide

The pioneering sanitary One-Nut Air-Operated Double-Diaphragm Plus (AODD+) pumps changed the industry by providing:

-

- Reduced downtime through simplified assembly/disassembly

- Savings in easier maintenance and increased performance

- Best-in-class, when Clean-in-place is a requirement

- Easy / quick maintenance

- Self-draining

- 60% less product left in the pump than any competitor AODD pump, for reduced waste and more efficient cleaning

- Ability to CIP or SIP (steam in place) at up to 7Bar / 100 psi

UHT engineers can provide bespoke pumping solutions to meet your needs, with applications experts working together with you to put the right solution into your production facility.

Quick Links

A Flotronic AODD+ payback is far faster than a traditional AODD!

Discover how quickly you can recover your costs—use our AODD Maintenance Payback Calculator to see your return in just a few clicks!

Frequently Asked Questions

What is a diaphragm pump used for?

Diaphragm (AODD) pumps excel in transferring sensitive food products, pharmaceuticals, and cosmetics where gentle handling is crucial. They're ideal for viscous fluids, shear-sensitive materials, and products containing solids. Common applications include transferring yogurt, sauces, purees, and slurries. Their ability to run dry and self-prime makes them particularly valuable in batch processing operations.

What are the advantages of a diaphragm pump?

Diaphragm (AODD) pumps offer numerous significant advantages that make them particularly valuable in various industrial applications. Their key benefits include the ability to run dry without damage, excellent handling of viscous fluids and solid-containing materials, and consistent flow rates regardless of discharge pressure. They excel at gentle product handling, making them ideal for shear-sensitive materials, while their self-priming capability and simple maintenance requirements contribute to reliable operations. Additionally, their design allows for easy cleaning and maintenance, and they can operate without electrical components, making them both versatile and dependable for a wide range of pumping applications.

What is a food grade pump?

The term "food grade" specifically indicates compliance with FDA 21 CFR 177 and similar global standards. Food grade pumps must meet FDA, 3A, and EHEDG standards for material compatibility and cleanability. Food grade compliance requires non-contaminating materials on gaskets and seal, stainless-steel construction, polished surface finish, sanitary connections, and a crevice free design. Some pump manufacturers mill pump housings out of a single billet of steel to avoid seams and welds that could harbor bacteria.

What type of pump is used in the food industry?

At least six types of hygienic pumps are commonly used in the food industry, including AODD pumps, lobe pumps, gear pumps, screw pumps, progressive cavity pumps, and centrifugal pumps. To be FDA-compliant, the materials of construction must be food grade. The best pump for foodstuffs depends on the product viscosity, product sensitivity to shear, size of entrained solids, requirements of the application (priming, deadheading, pulsation), ease of cleaning and . Key types include:

- AODD pumps for viscous, self-priming applications.

- Lobe pumps for viscous products.

- Gear pumps for filling applications.

- Centrifugal pumps for high-volume, low-viscosity transfer.

Which pumps are generally used for heavy solids?

AODD pumps lead in handling heavy solids due to their large flow paths and gentle operation. Other suitable options include:

- Progressive cavity pumps for abrasive slurries.

- Peristaltic pumps for concentrated solids.

- Heavy-duty centrifugal pumps with specialized impellers.

- These pumps can handle particle sizes up to 75% of the pump's inlet size.

From the Blog

View BlogTwin Screw vs. Lobe Pump? Which Pump is the Better Choice for Suspended Solids?

As food processors respond to rising consumer demand for protein-enriched products, from high-protein yogurts to enhanced dairy beverages, production lines face increasing challenges with thick, viscous formulations. With the food processing automation market approaching $40 billion by 2030, the industry seeks equipment capable of handling complex products without compromising throughput or quality.

Read BlogComparing Hygienic Pump Technology Pros and Cons: A Process Engineer’s Guide

In hygienic processing environments, pump selection plays a far greater role than simply moving product from point A to point B. The pump directly influences product integrity, ensuring easy cleaning, reducing food safety risks, minimizing maintenance efforts, and lowering total cost of ownership. For process engineers working in food, beverage, personal care, or pharmaceutical applications, understanding which hygienic pump technology is best designed for each application is essential to building reliable, repeatable processes.

Read BlogChallenging Pump Applications, Meet Your Match

The ultimate guide to knowing when to use twin screw pump technology —don’t let viscosity slow you down

Read Blog